Hard skiving: An alternative to grinding or honing

The hard skiving process opens up new possibilities in hard-fine machining internal gears and splines, which, when processes like grinding or honing are used, are difficult, unproductive or impossible to achieve. It can even out hardening distortion in a targeted fashion, stands out for its high flexibility, long tool life and economic efficiency, and can be used by simply changing the tool on the Liebherr-Verzahntechnik GmbH gear skiving machines.

Hard-fine machining gears is gradually becoming an indispensable process, especially in e-mobility, due to greater demands on service life, load capacities and noise levels. In some component geometries, conventional methods like honing or profile grinding are reaching their limits, either in terms of component size or productivity.

The hard skiving option for complex geometries

Based on the kinematics of gear skiving, hard skiving opens up a cost-effective solution for hard-fine machining, even for geometrically challenging components. These include internal gears with large diameters or wide tooth widths, especially if there is heavy heat treat distortion, and splines. The service lives of hard skiving tools are similar to those used in soft machining. This will now give users another, cost-effective machining option to specifically compensate for hardening distortions on such components.

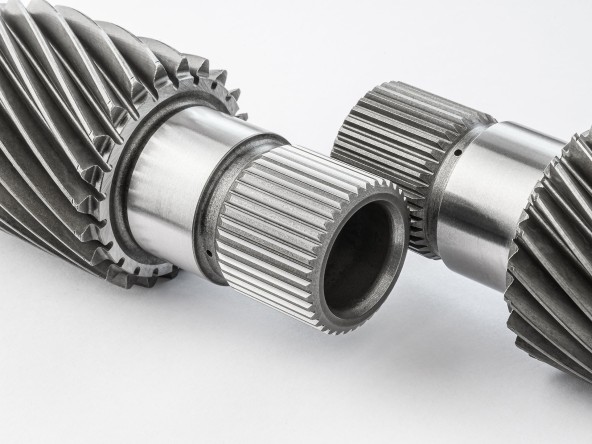

Hard-skived spline (before and after machining)

Balance between quality and economic efficiency

Hard skiving offers an effective balance between attainable quality and economic efficiency for challenging internal gears, even in small and medium series production, for example in e-mobility, aviation, defense technology or in special machine manufacturing. Typical applications are, for example, planetary gears for commercial vehicles for which the increased load capacity is the first priority, but maximum smooth running or noise reduction are secondary. The attainable surface quality is slightly below that of grinding, but fully fulfills the requirements of many industrial applications. Hard skiving enables targeted quality correcting after hardening, even for splines.

Integration on gear skiving machines

Soft and hard machining can be combined by simple tool changes on gear skiving machines in the LK series. The method is suitable for both dry and wet machining. During a customer trial with an internal gear, hard skiving performed after hardening reduced the reject rate from up to 30% to almost zero.

Liebherr – experienced technology partner

The increasing number of trial requests emphasizes the high level of interest in hard skiving applications. Dr. Oliver Winkel, Head of Application technology, explains: “Many customers still lack experience in this technology, there are barely any publications and literature on the subject. To build up the know-how required, it is essential to collaborate closely with experienced technology partners. We offer experience over many years, in machines, tools and technology alike.” Ben Sheen, Engineering Specialist at the Eaton Mobility Group, says: “The trials with Liebherr produced prototype parts, the basis of which gives us a strong decision making capability.” This shows: Hard skiving has established itself as a practical addition to conventional methods, especially where flexibility, economic efficiency and functional quality are required.