BAT 350

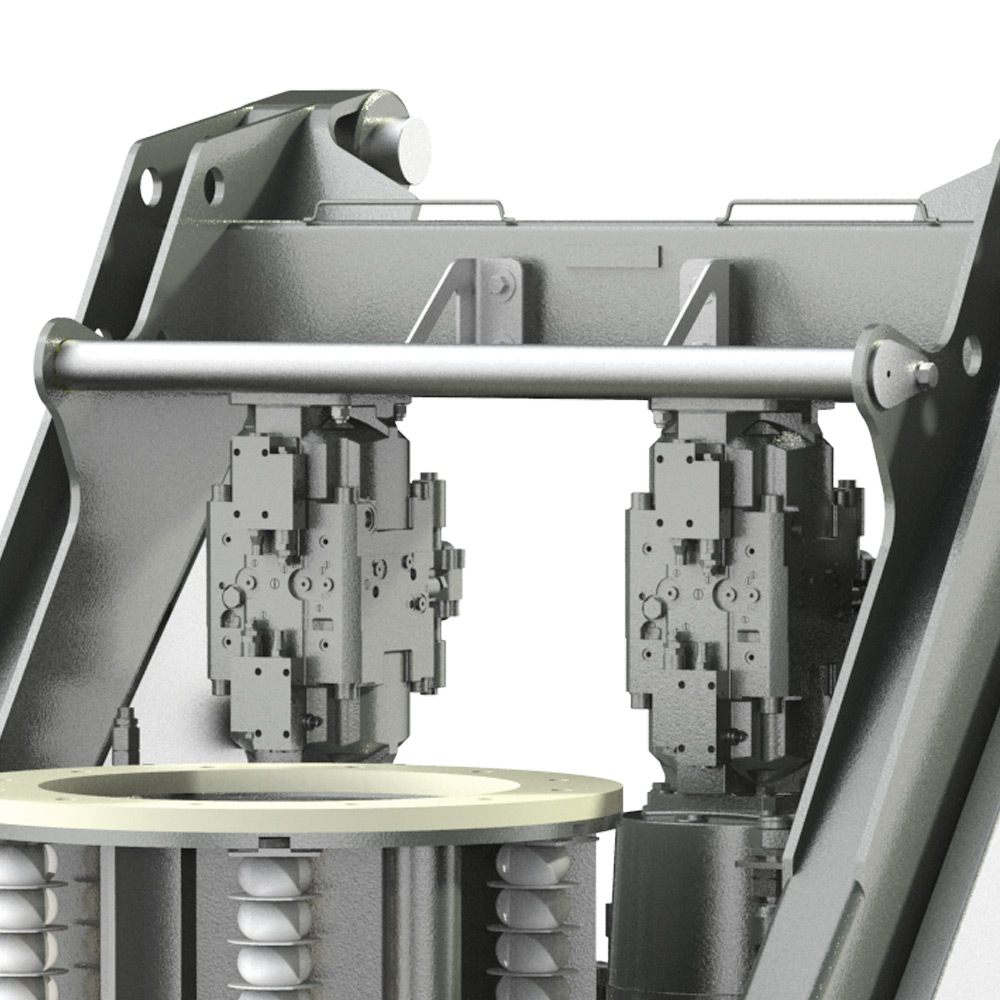

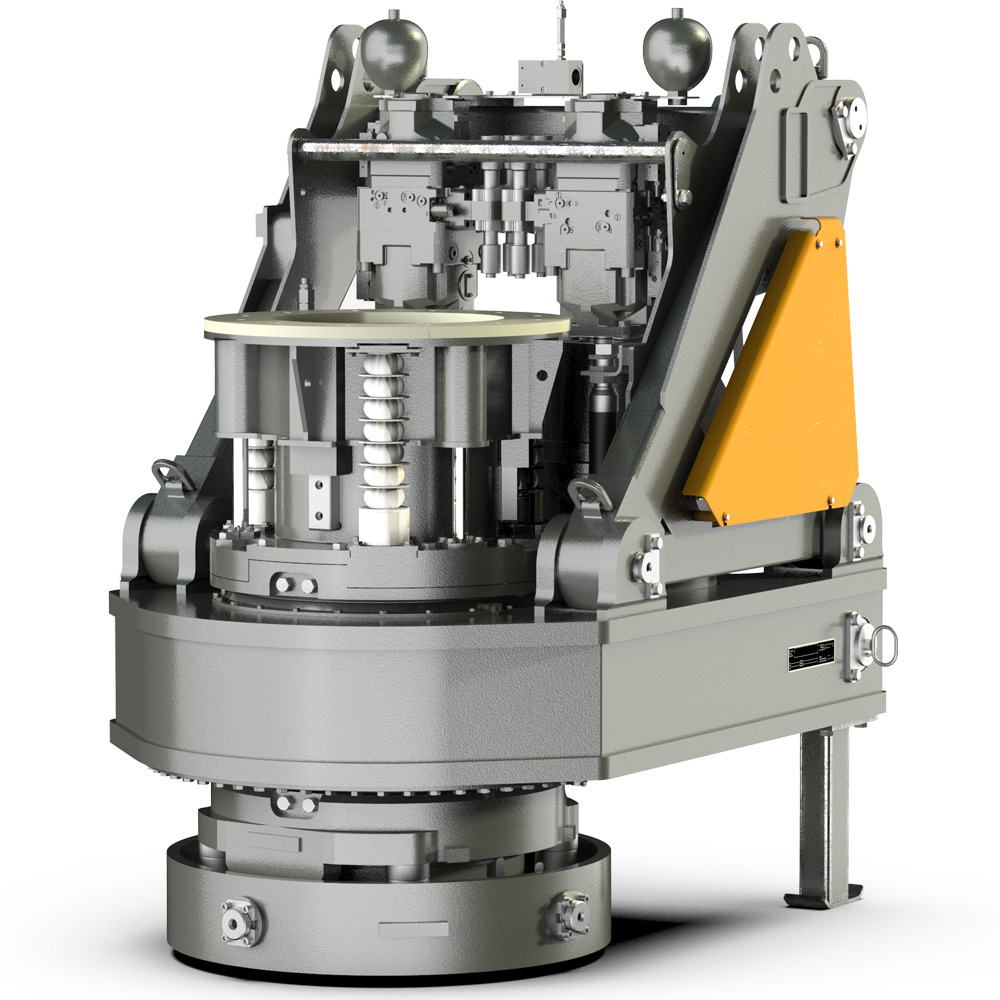

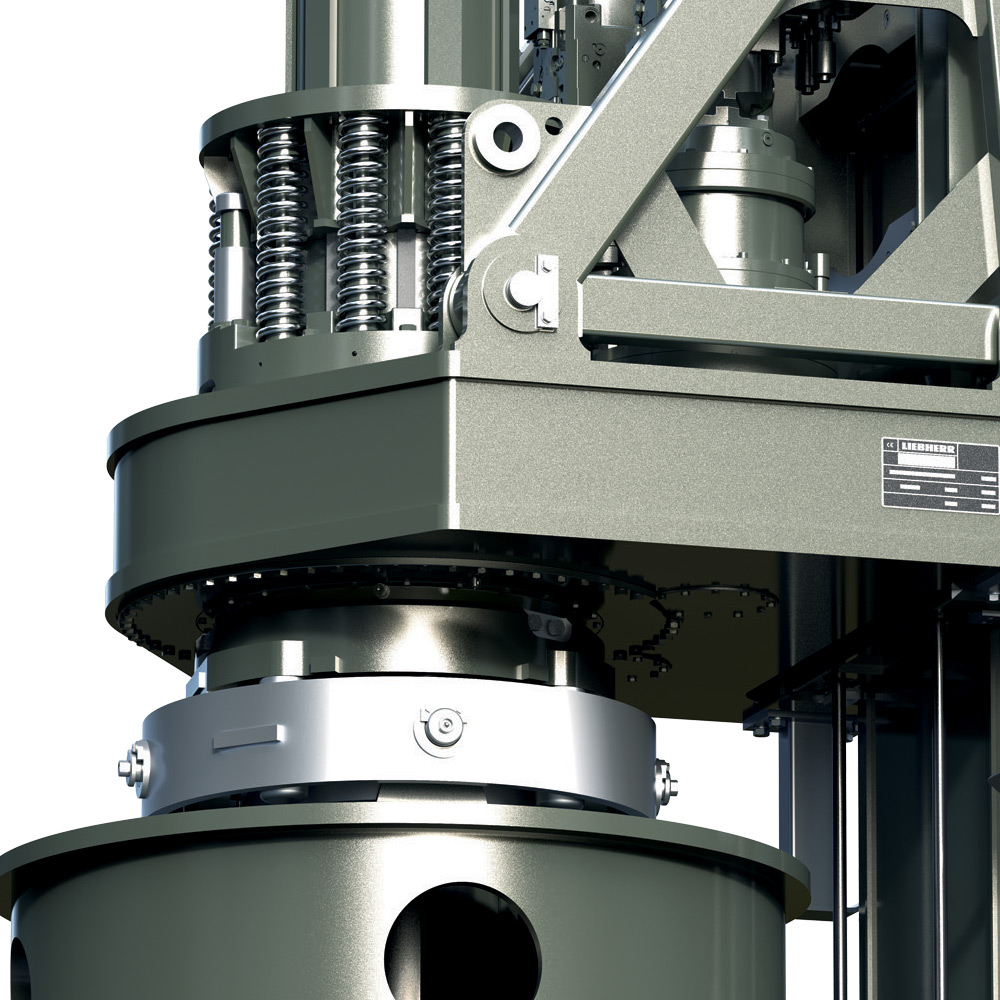

Rotary drive (BAT series)

The powerful rotary drive delivers the required torque for common drilling applications such as Kelly, continuous flight auger or full displacement drilling. Considerable advantages are the automatic torque regulation as well as four electronically adjustable speed ranges. The rotary drive is powered by the on-board hydraulics of the LB 35 carrier machine.

Torque - 347 kNm

347 kNm

Speed - 46 U/min

46 U/min