Applications

Crawler cranes are the construction industry's heavyweights, effortlessly navigating every terrain. The preferred choice for heavy-duty projects in construction and beyond, crawler cranes bring the power and finesse needed to get the job done.

01/06

01/05

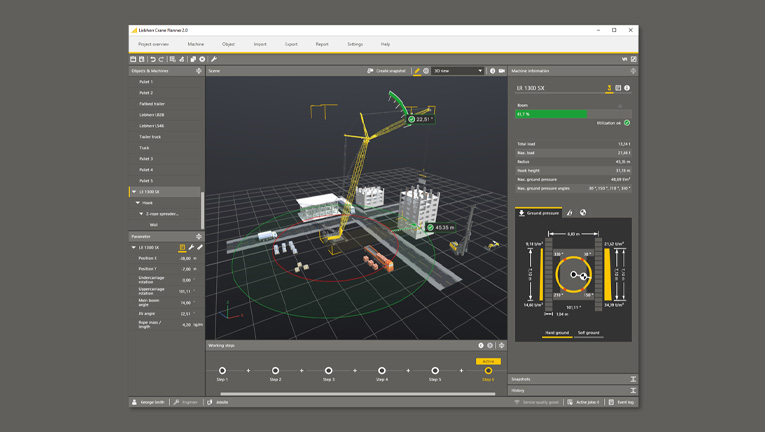

Advanced technologies

01/03