For this pile driving method a vibrator brings the piling element into harmonious longitudinal oscillation. This oscillation is transferred from the piling element to the directly adjacent soil. Thus, the friction along the piling element is significantly reduced during the pile driving process. Due to the weight of the vibrator or pushing with the help of the crowd system the piling element can be installed in the ground. The piling elements can also be extracted following the same principle.

When using high-frequency vibrators with variable static moment, noise and vibrations levels are especially low. Subsequently, it is also possible to carry out vibrating work directly next to sensitive buildings. If the vibrator is guided on a leader, crowd forces can be transferred.

Video vibrating

Machines

Animation video: LRB 16 / LRB 18

One of the most common types of application for the LRB 16 / LRB 18 is the installation of slurry walls.

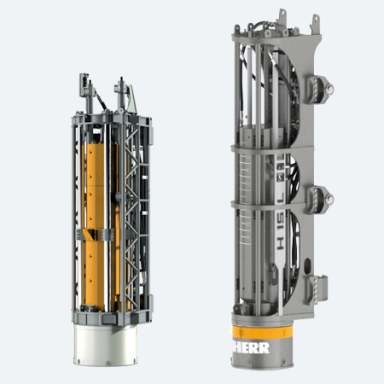

LV 20 vibrator slim design

The Liebherr vibrator LV 20 achieves a static moment of up to 20 kgm. The maximum centrifugal force amounts to 1160 kN. Thanks to the use of new materials it is subject to low wear. In addition a new cooling system significantly increases its service life.