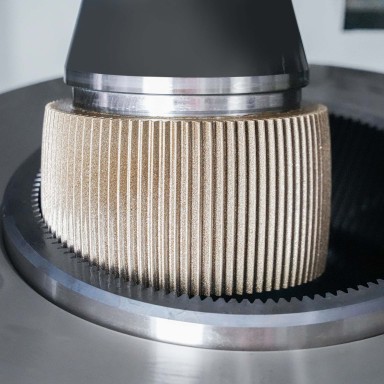

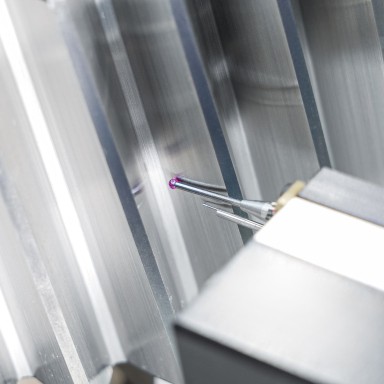

Gear Seminar in Brazil

In November 2024 Liebherr Brasil LTDA held one of its renowned Gear Seminars on gear technology in Guaratinguetá, Brazil. Industry experts were in the spotlight as their presentations focused on grinding, soft machining and measuring technologies. The program provided the wide range of participants with well-grounded technical knowledge and practical know-how, and showcased the expertise and services available at the Brazilian site. The accompanying program offered space for knowledge sharing and direct networking.