01

Earthmoving and material handling

Hydraulic cylinders – power and precision for every industry

Our expertise covers a wide range of applications – from the demanding conditions of mining to the high‑precision requirements of of maritime applications. Delivering robust and reliable cylinders is at the core of our work. At the same time, we stay closely aligned with technological developments and invest in advanced pre‑development projects to help shape future innovations. This enables us to create solutions that meet current market needs while supporting long‑term goals such as reducing emissions and driving digital transformation.

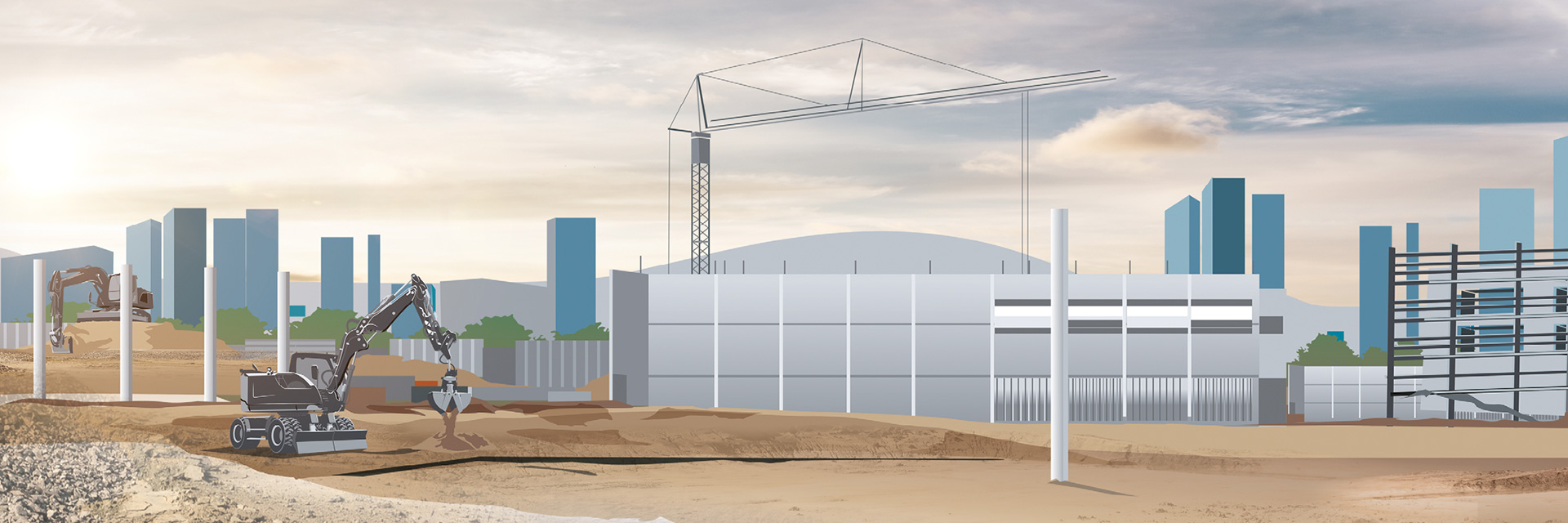

Earth moving and material handling

Hydraulic cylinders for earthmoving applications

On construction sites around the world, mobile machinery operates under extreme conditions such as dust, dirt, water and cold. Liebherr provides robust, reliable and application‑specific hydraulic cylinders designed for continuous, long‑term use.

Mobile and crawler excavators face frequent load changes, which pose a particular challenge. Liebherr’s proven components withstand these stresses with ease, increasing both efficiency and operational safety.

The 380‑bar series is ideally suited for highly dynamic mobile applications. With 40 basic variants and numerous options, it offers maximum flexibility for a wide range of construction machines.

The versatile Liebherr A 918 mobile excavator is used primarily on urban construction sites and in landscaping. Its powerful hydraulic cylinders enable precise movements during continuous operation.

Wheel loaders are high‑performance machines for material handling. Our hydraulic cylinders convert hydraulic pressure into motion and control the lifting, lowering and tilting of the bucket.

Telehandlers are agile machines for lifting and moving loads at varying heights. Our hydraulic cylinders control the extension of the telescopic boom as well as the precise lifting and tilting of the load.

Dump trucks are robust transport vehicles used in mining and on large construction sites. Our hydraulic cylinders powerfully raise and lower the dump body to unload material safely and efficiently.

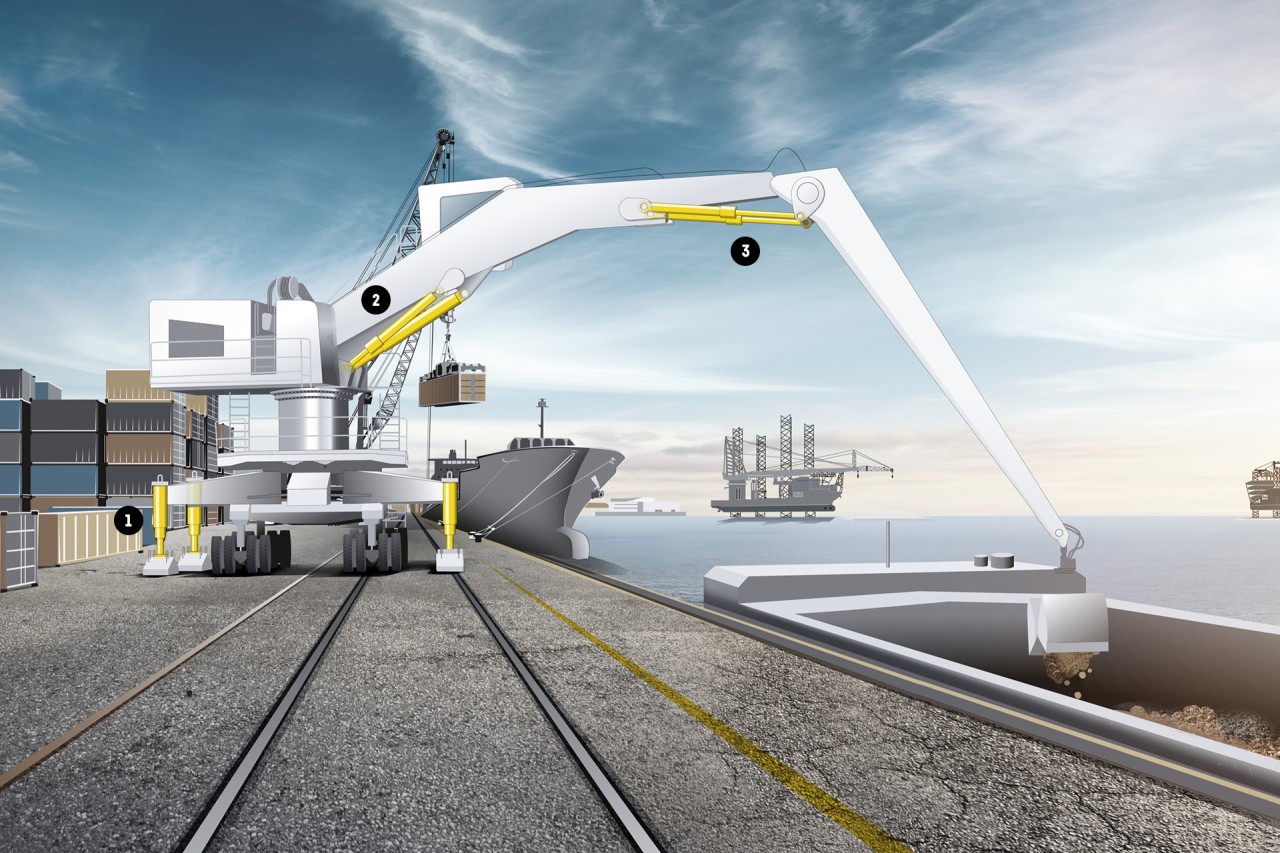

Mobile and crawler cranes

Mobile and crawler cranes

Powerful, precise movements are essential in crane technology. Our hydraulic cylinders for mobile cranes ensure stable and controlled motion, even when handling heavy loads, contributing to the safety and efficiency of crane operations. Their robust design guarantees long service life under extreme conditions.

The lightweight cylinders combine the advantages of high‑strength materials with an optimised weight design.

Advantages of our integrated valve technology – directly inside the support cylinder:

- Less pressure loss and increased energy efficiency

- Compact design

- Reduced piping

- Effective reduction of potential error sources

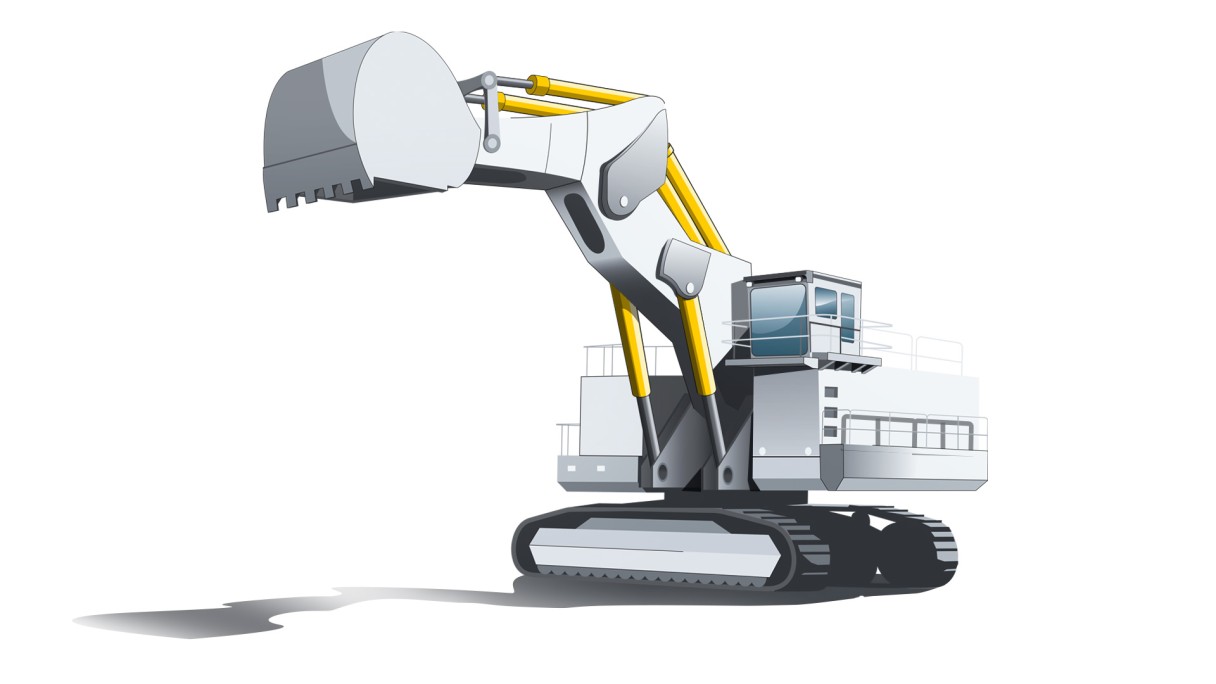

Mining

Hydraulic cylinders for mining

In continuous operation under the toughest conditions – hydraulic cylinders for mining excavators must withstand extremely high static and dynamic forces. These requirements are met through a robust, longevity‑focused design and a specialised selection of materials based on decades of experience. For example, Liebherr manufactures the piston rod from a single high‑strength forged piece.

By reducing weight, particularly in the bucket and stick cylinders of a mining excavator, efficiency can be significantly increased. Depending on customer requirements, Liebherr offers various weight‑saving concepts even for highly dynamic applications, such as the use of carbon‑fibre‑reinforced plastic (CFRP).

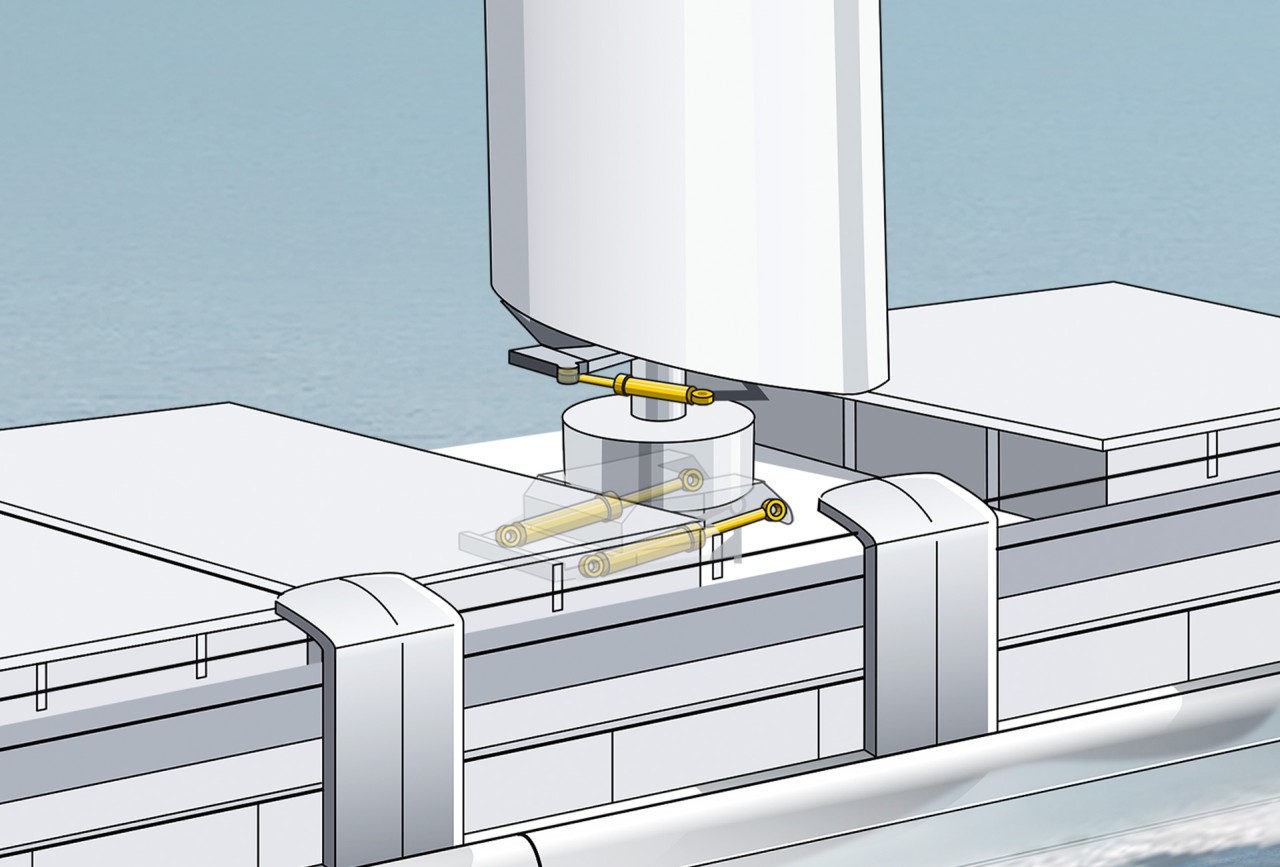

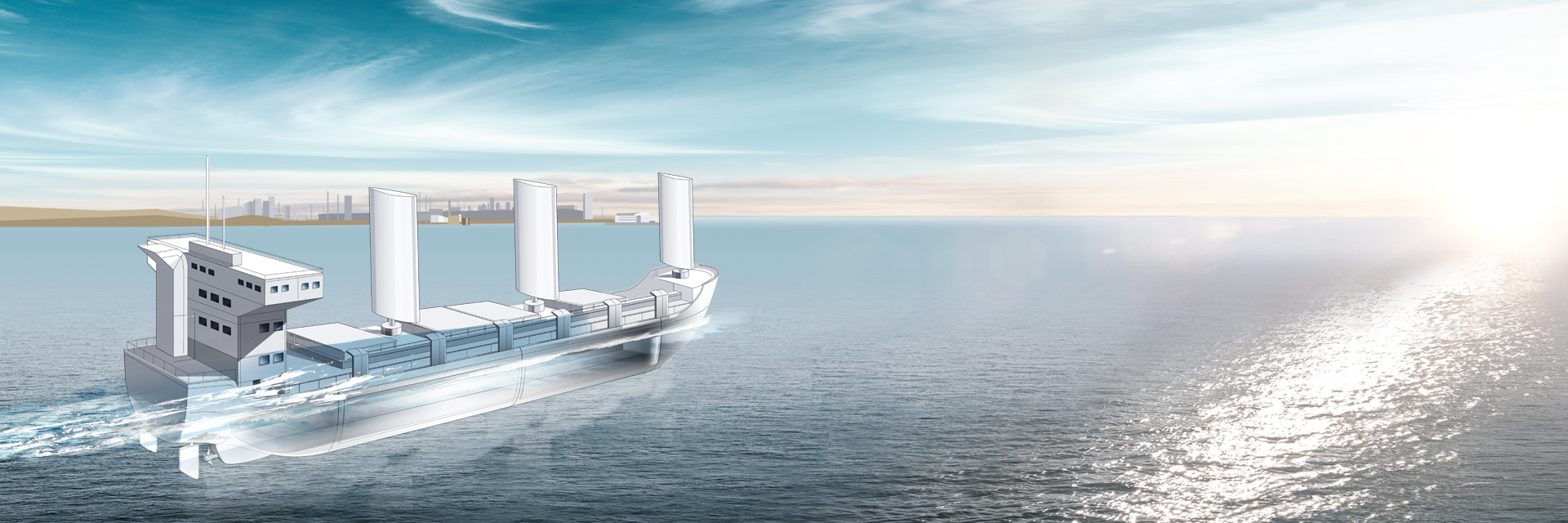

Maritime applications

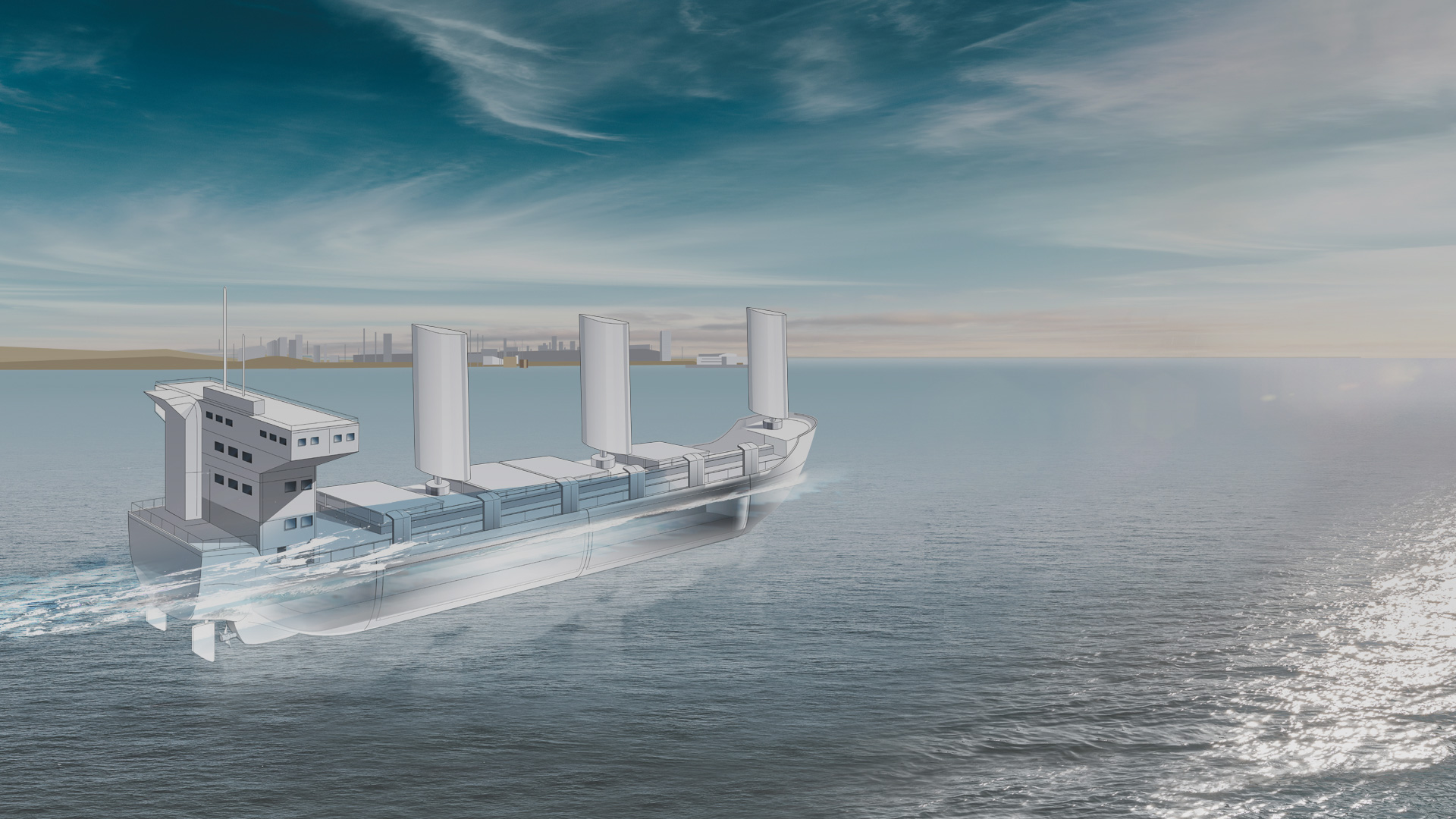

Hydraulic cylinders for maritime applications

Liebherr manufactures offshore‑certified, corrosion‑resistant and durable hydraulic cylinders for cargo vessels. They are responsible for lifting and lowering the sail mast as well as extending and retracting the two‑part wing sails.