T 284

The last word in productivity

The Liebherr T 284 mining truck is the successor of Liebherr’s popular T 282 C. It continues to be the lightest and most capable ultra-class mining truck that also happens to reduce fuel consumption on site, helping customers to meet production targets with fewer trucks, or in less time.

Payload class - 363.00 t

363.00 t

Gross vehicle weight (GVW) - 605.00 t

605.00 t

Gross power - 2,720 kW

2,720 kW

T 284 highlights:

Lower cost per tonne

Advanced technology

Proven reliability

Technical data

| Payload class | 363.00 t |

| Gross vehicle weight (GVW) | 605.00 t |

| Empty vehicle weight (EVW) | 242.00 t |

| Engine model | MTU 20V4000 C22 |

| Gross power | 2,720 kW |

| Engine model (option A) | Liebherr D9816 |

| Gross power (option A) | 2,700 kW |

| Engine model (option B) | MTU 20V4000 C23L |

| Gross power (option B) | 3,000 kW |

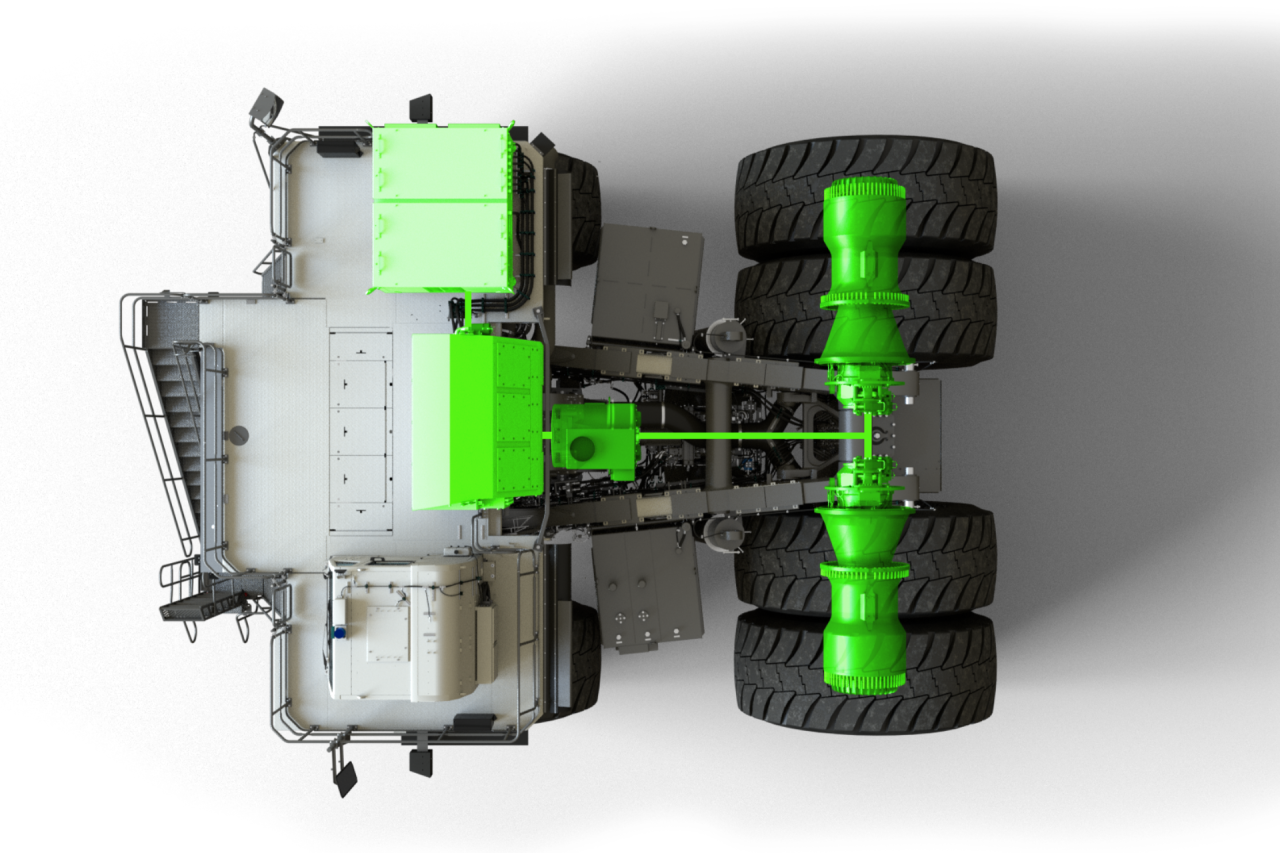

| Drive system | Liebherr Litronic Plus AC drive system with IGBT technology |

| Max speed | 64 km/h |

| Tire sizes - standard | 59/80R63 |

| Tire sizes - optional | 56/80R63 |

Downloads

Videos

T 284 product video

Machine gallery

Innovative design and technologies powering the T 284

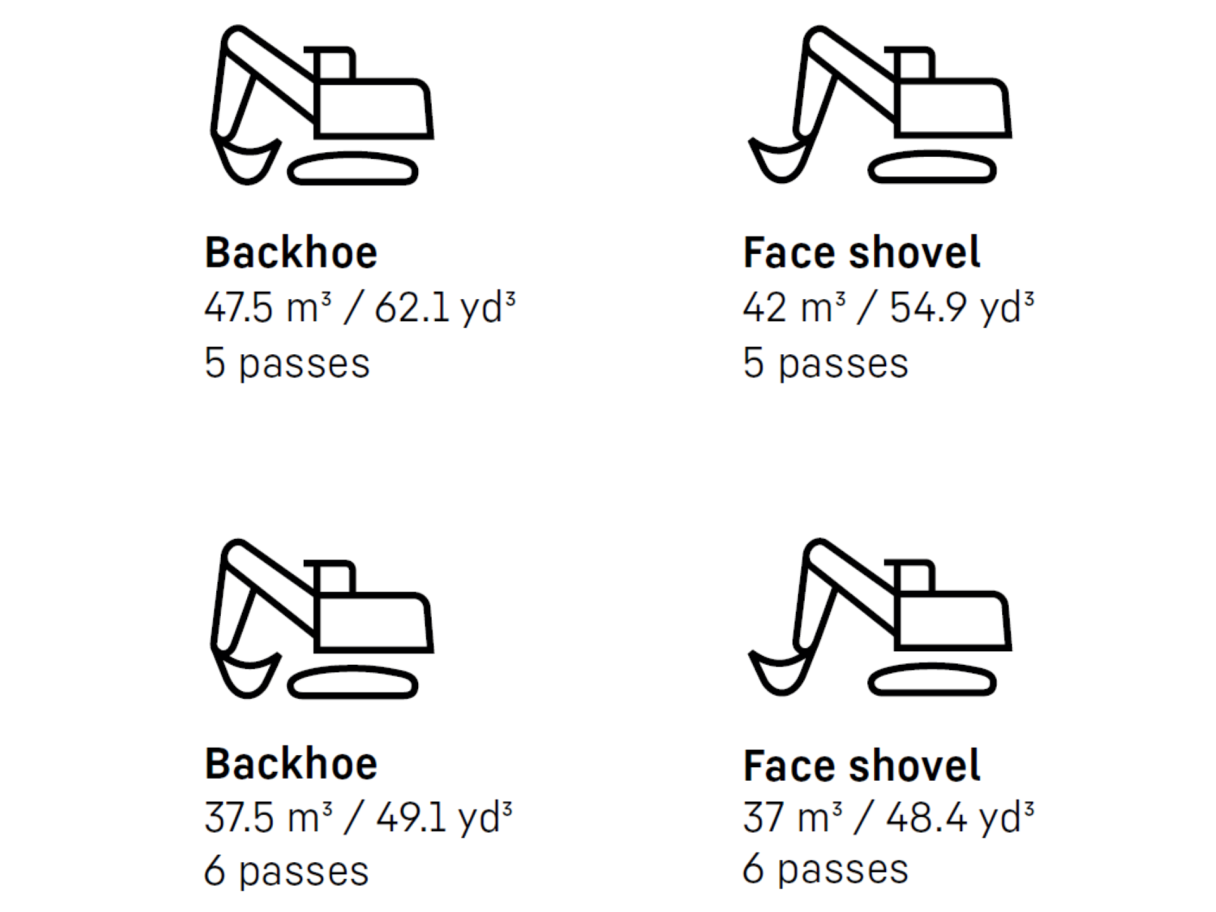

Truck excavator match*

*Site-specific factors like loose material density, bucket size, fill factors, truck body size and payload capacity will influence pass match. Contact your local Liebherr sales and service company or sales partner for analysis of your site.

The perfect Liebherr pairing

The T 284 is the perfect match for the R 9600 and R 9800 excavator. With these combinations, you can discover the seamless synergy between our cutting-edge excavators and high-performance mining trucks that sets new standards for excellence in the industry.