5 minutes - magazine 02 | 2025

Once upon a time, 40 years ago ...

In the spring of 1984, the town of Bad Wimpfen in Baden-Württemberg was shaken by a catastrophic fire. A lightning strike destroyed the entire roof of the Blue Tower, which had stood since around 1170 as the western keep of the royal palace.

A year later, specialists were hard at work installing a new roof on the spa townʼs famous landmark. A Liebherr LTM 1160 from the company Wiesbauer played a key role in this operation.

Rising 58 metres above the historic centre of Bad Wimpfen, the Blue Tower presented a challenging worksite, with narrow access roads and confined spaces. Fortunately, the LTM 1160 was both compact and manoeuvrable. Once the six-axle machine – the most powerful all-terrain crane on the market at that time – was positioned, the crane operator and crew began the setup process. The sliding beams and support cylinders were extended individually or in unison. The operation demanded both experience and a meticulous approach to ensure the safety of personnel, crane and load at all times. It took around 45 minutes to get the six-axle machine ready for use.

Once the new 16-tonne roof structure was prepared for lifting, the crane’s slewing platform was rotated into position, and the telescopic boom – already fitted with a lattice jib – was extended to a lifting height of 50 metres. On the LTM 1160, the individual sections of the telescopic boom were locked together via a pneumatic-mechanical system, providing exceptional structural stability and torsional rigidity.

The crane driver guided the hoist gear upwards with precision. Throughout the process, the electronic load moment limiter monitored every phase of the lift. Digital displays provided real-time information on the actual load weight, working radius and boom length.

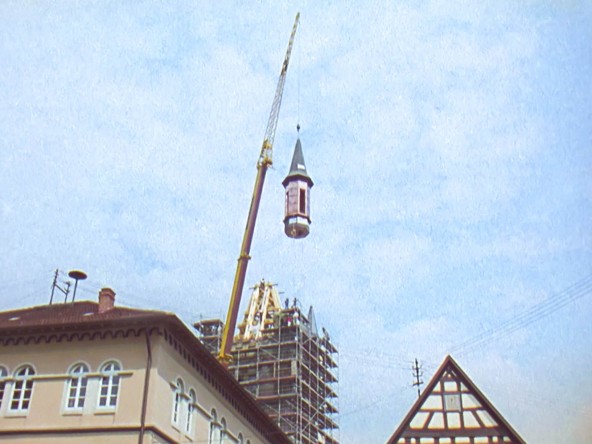

In 1985, a crane assembly operation of this complexity was anything but routine, and many local residents gathered to witness the spectacle, capturing it on film and camera. Mayor Klaus Czernuska commented: “Last year, we initiated all the preparations for the reconstruction. And today, on 8 May, we’re finally able to complete the entire roof installation. The spire is being lifted at the same time – it’s a very important day for our town, because the Blue Tower is the symbol of Bad Wimpfen.”

Thanks to the crane’s clear instrumentation and ergonomic armrest controls, the operator was able to focus entirely on the task at hand. As the roof structure moved out of view, he received precise radio instructions from the assembly supervisor, allowing the load to be slewed into position with millimetre accuracy.

The new roof was already the third in the towerʼs long history. Following a Gothic construction and a Baroque dome, the town had opted for a faithful reconstruction of the original Romanesque-style roof truss. The carpenters’ craftsmanship played a decisive role in ensuring that the structure was a perfect fit. After withstanding the lift without any distortion, the timber framework was guided precisely into its anchoring points via radio. The previous year’s fire had also severely damaged the roofs of the four corner turrets, which now had to be replaced. To install the 3.3-tonne pointed roofs, the crane was fitted with a 20-metre folding jib attached to its 44-metre telescopic boom. Modern crane technology significantly eased the job for the specialists – the mobile crane’s electrohydraulic control system enabled smooth, finely tuned movements throughout the operation.

The bell tower, with its slate-covered spire and 800-kilogram bell, weighed over seven tonnes. It, too, was lifted into place at a height of 64 metres. On the night of the fire, the bell broke free as its mountings gave way in the heat, causing damage as it crashed down inside the tower.

Thanks to cutting-edge crane technology – and above all to the outstanding teamwork between crane operator and carpenters – the complex tower installation was completed in just one day. “At last, we have our Blue Tower back – and now everyone in Wimpfen can sleep soundly again,” said a delighted Mayor Klaus Czernuska.

“Construction sites keep getting more challenging and complex,” one of the carpenters said. “Especially when working on old buildings or large structures, we increasingly rely on technical equipment. We’ve been working with Liebherr cranes for years. They lift our timber structures into place with millimetre precision. We’ve always been satisfied and never had any issues.”

This article was published in the UpLoad magazine 02 | 2025.