Point Pilot makes it possible to save up to three hook positions, which can be repeatedly and accurately accessed as required.

Route Pilot allows the crane operator to define two separate routes that can be travelled both forwards and back again. Even stopping along the route is possible.

Positioning Pilot

Positioning Pilot allows the crane to approach stored points semi-automatically and also to move along pre-plotted routes. All semi-automated crane travel movements are sway-free thanks to the battery-powered IMU sensor system on the hook block. Point Pilot and Route Pilot functions make up this assistant.

Positioning Pilot is most useful for repetitive, monotonous lifting tasks. Examples here are concreting work and lorry unloading processes, where the crane hook is moved back and forth several times between two locations. The semi-automated approaching of stored points and travelling along mapped routes speeds up workflows on site, reduces crane operator workload and increases safety thanks to predefined movement.

Use examples

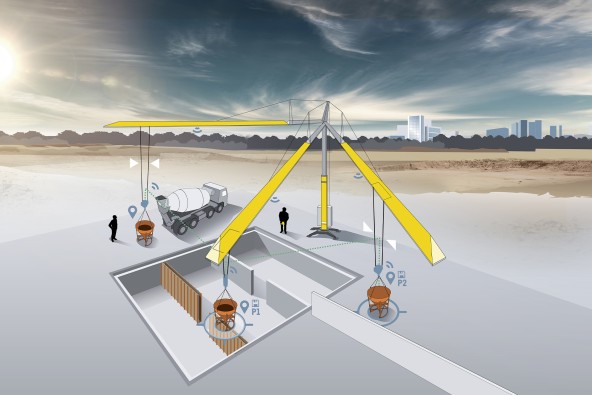

Repeat movements and set target positions for concreting work

Time is of the essence with concreting work, plus the crane often has to travel the same route over and over to transport the concrete bucket from the truck mixer to the installation site and back again. The truck mixer’s unloading position is also usually fixed due to the limited space available.

Solution: Route Pilot

The assistant allows a route to be mapped for these repetitive movements. The crane can then travel the route semi-automatically, which in turn speeds up the workflow and reduces the crane operator’s workload while the predefined route also increases safety.

Solution: Point Pilot

The assistant can store the truck mixer’s fixed unloading point and a point of choice near the work area as targets, and guide the crane to them semi-automatically. This allows the concrete bucket to be transported safely and efficiently between the respective points, speeding up the construction process and increasing safety at the same time.

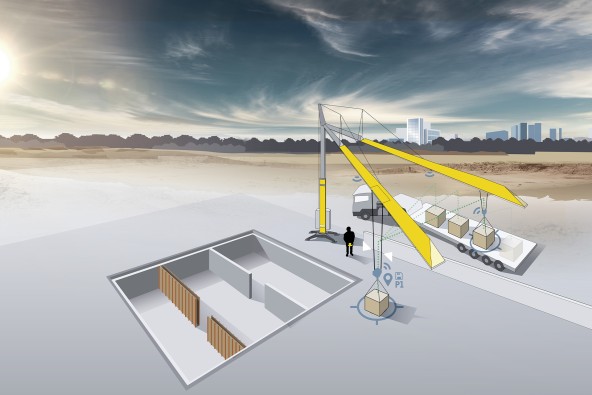

Efficient unloading processes on construction sites with regular deliveries and for storage yard cranes

Construction sites that receive regular deliveries of materials often require them to be unloaded quickly and transported to specified locations. These processes are repeated on a daily or weekly basis and require precise operation to keep efficiency high.

Solution: Route Pilot

The crane operator plots the route from the unloading point to the storage area just once. This route can then be travelled semi-automatically and repeatedly in both directions, which minimises the risk of damage, increases convenience and speeds up the work process.

Solution: Point Pilot

The assistant can store the usual unloading positions and storage zones and approach them automatically, which speeds up the unloading process and reduces the effort needed by the operator. The automatic lifting of the load to a safe height also assures safety during unloading.

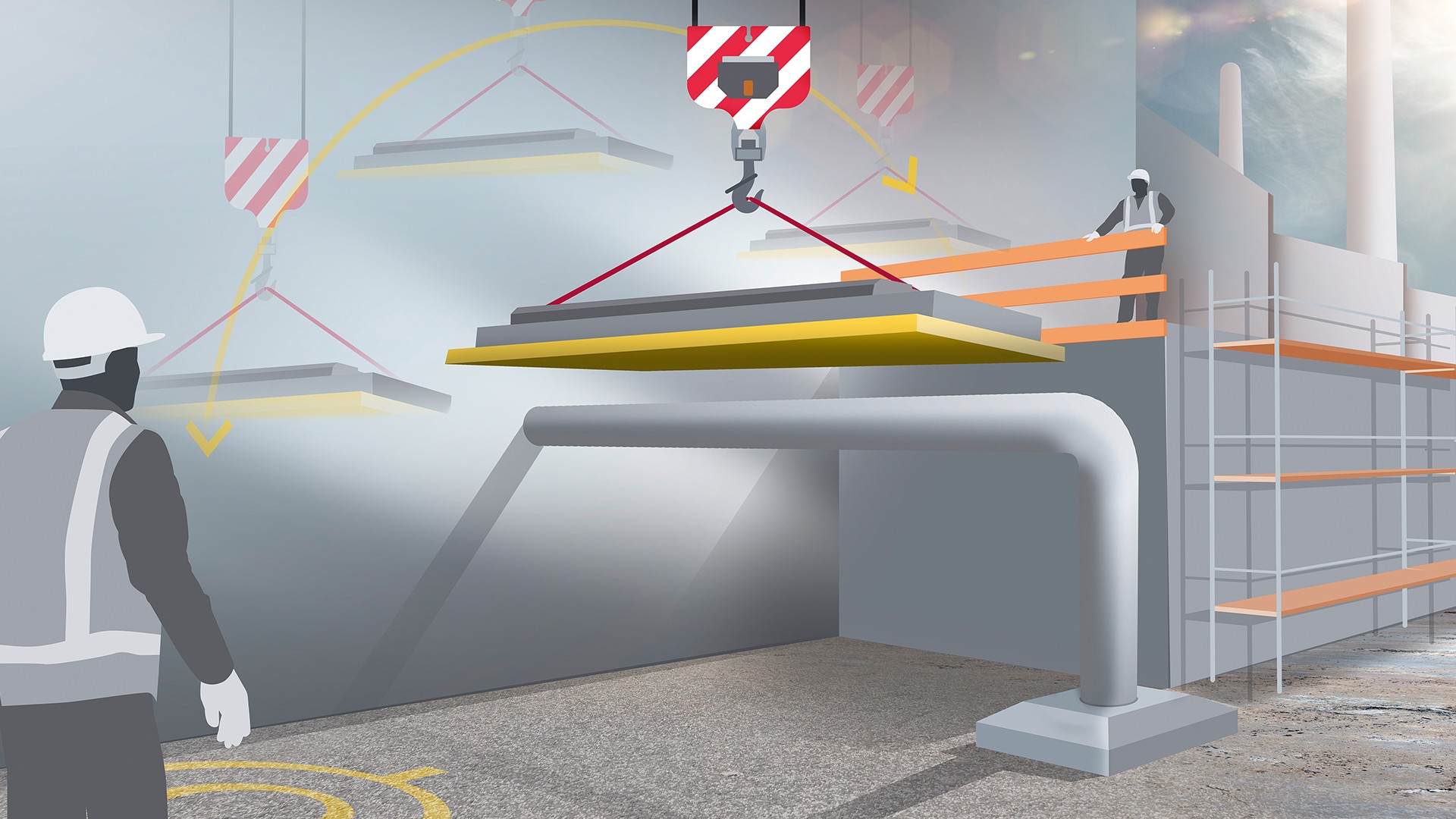

Safe transport of components when working near obstacles

Construction projects that take place near obstacles like buildings, scaffolding or other cranes carry a high risk of the load colliding during transport. It is therefore essential that loads are moved at a safe height to avoid accidents.

Solution: Point Pilot

The assistant ensures that the load is always positioned at a safe height before it is moved in either slewing or trolley direction. This minimises the risk of collisions and increases safety when working in complex environments.

Precise lifting of sensitive loads in tight environments

In confined construction site areas, e.g. the interior of large buildings or metro and tunnel sites, sensitive loads like glass fronts, prefabricated concrete parts and tunnel half-shells need to be transported without colliding with obstacles.

Solution: Route Pilot

The assistant maps out the ideal route for transporting these sensitive loads for precise and safe movement. This route can then be travelled semi-automatically and as many times as needed, which minimises the risk of damage and speeds up the work process.

Safe carrying out of lifting tasks in sensitive environments

In environments where special safety precautions apply, such as on chemical or nuclear power plant construction sites, lifting operations have to be carried out in a particularly precise and controlled manner to minimise the risk of accidents.

Solution: Route Pilot

The assistant maps out the safest route for the hook to avoid obstacles and sensitive areas. This route can then be travelled semi-automatically, increasing both safety and reliability of lifting operations in these sensitive environments.

Other assistance systems

Notes on use:

- The crane operator is responsible for lifting and moving the load safely. The assistance systems are there to provide support. Liebherr recommends that crane operators undergo crane operator training.

- The assistance systems are not always useful in all lifting situations, e.g. in confined areas, which is why they can be activated and deactivated at any time.