LTM 1100-5.3

Mobile crane

LTM 1100-5.3 - The master of all roads.

A mobile crane that takes the combination of mobility, economy and performance to a whole new level – the LTM 1100-5.3 has a powerful, 62 metre (203 ft) telescopic boom and can carry up to 16.9 tonnes (37,250 lb) of ballast on public roads with an axle load of just 12 tonnes (26,450 lb). The crane is also suitable for economical global mobility as it can travel with an axle load of just 9 tonnes (19,840 lb). This is why we are launching the new LTM 1100-5.3 with the slogan “The master of all roads”. It is the second crane in Liebherr’s mobile crane portfolio to feature the new LICCON3 control system.

Max. load capacity - 100 t

100 t

Telescopic boom - 62 m

62 m

Max. hoist height - 76 m

76 m

Max. radius - 64 m

64 m

Number of axles - 5

5

What's inside

Suitable for global mobility:

Economical:

Large working range:

LICCON3:

Wear-free manoeuvring:

Variable support:

Technical data

| Max. load capacity | 100 t |

| at radius | 3.00 m |

| Telescopic boom from | 13.00 m |

| Telescopic boom up to | 62.00 m |

| Lattice jib from | 2.00 m |

| Lattice jib up to | 16.00 m |

| Drive engine/make | Liebherr |

| Drive engine | 6-Zylinder-Diesel |

| Drive engine/power | 400 kW |

| Number of axles | 5 |

| Drive/Steering standard | 10 x 6 x 10 |

| Drive/Steering option | 10 x 8 x 10 |

| Driving speed | 85.00 km/h |

| Total ballast | 22.50 t |

Downloads

Videos

The master of all roads

LTM 1100-5.3 - Streamlined, strong, aiming high

Boom/jib combinations

Boom/jib combinations

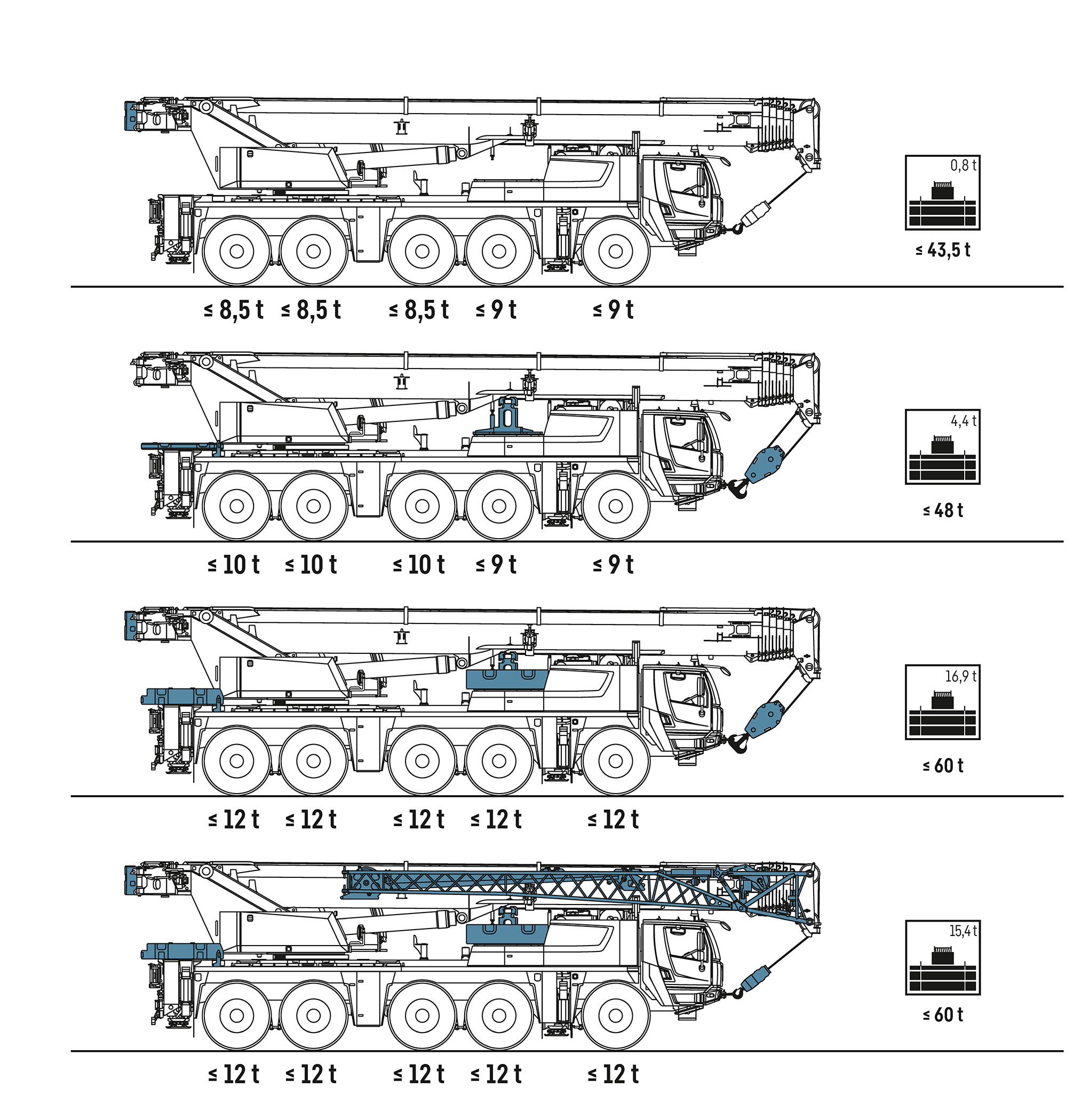

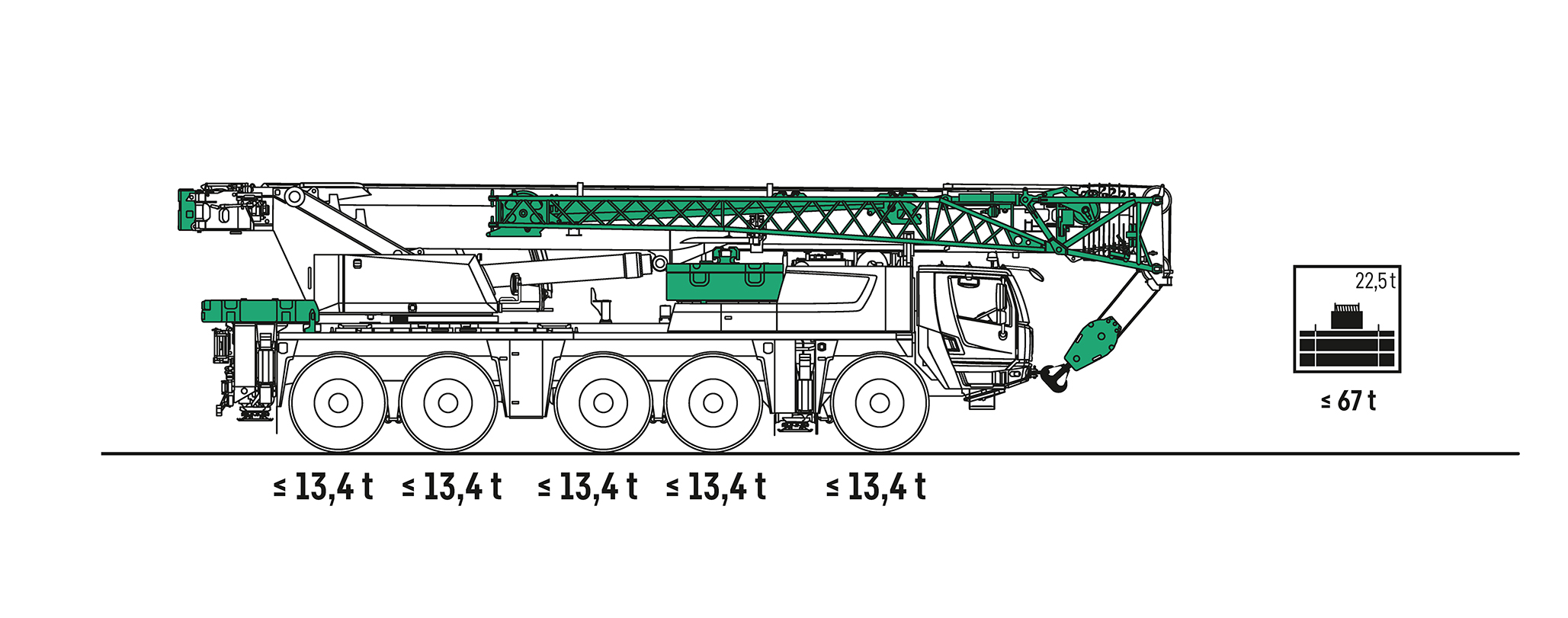

Driving conditions

On-road driving

Jobsite driving

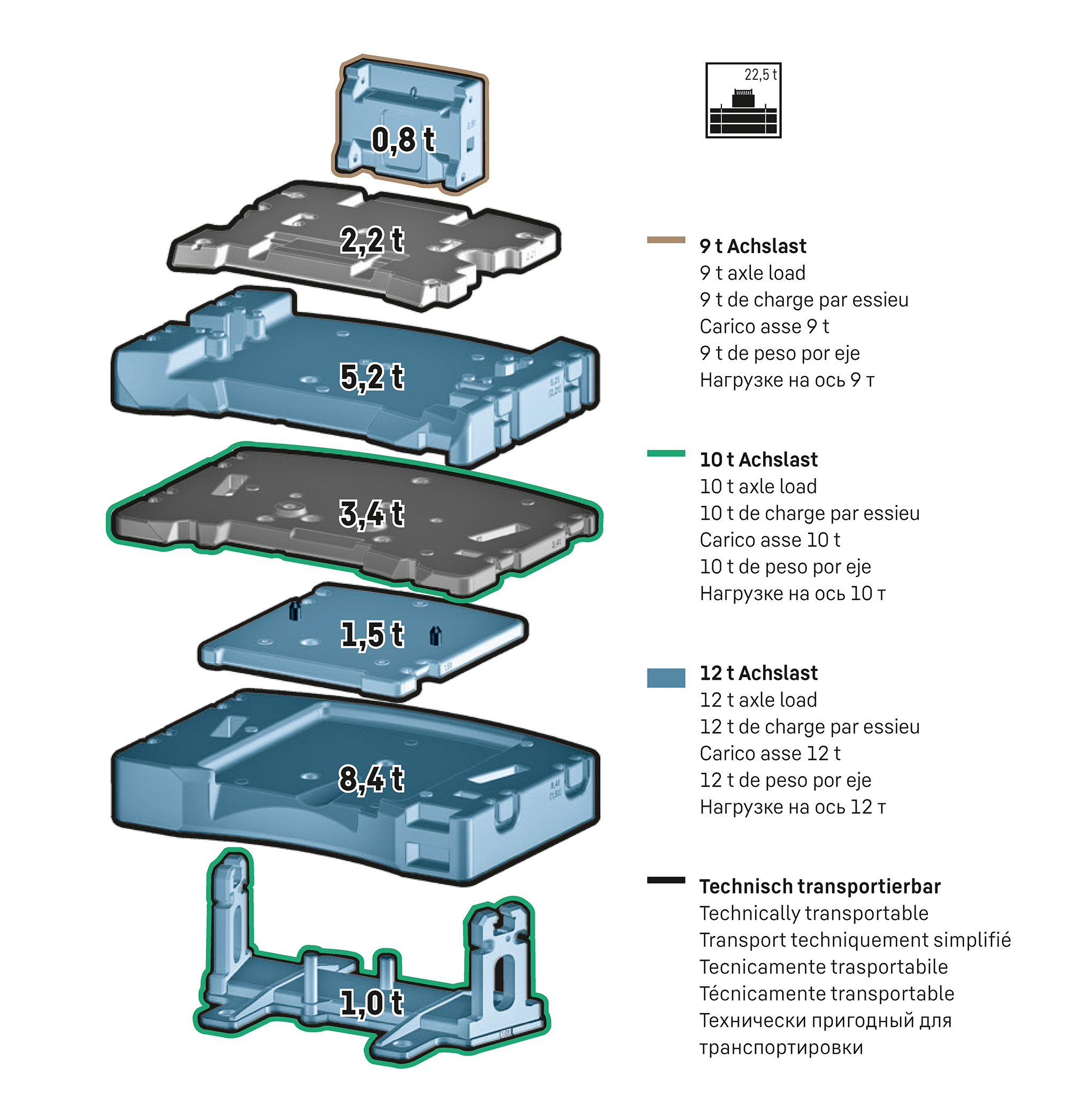

Ballast systems

Counterweight

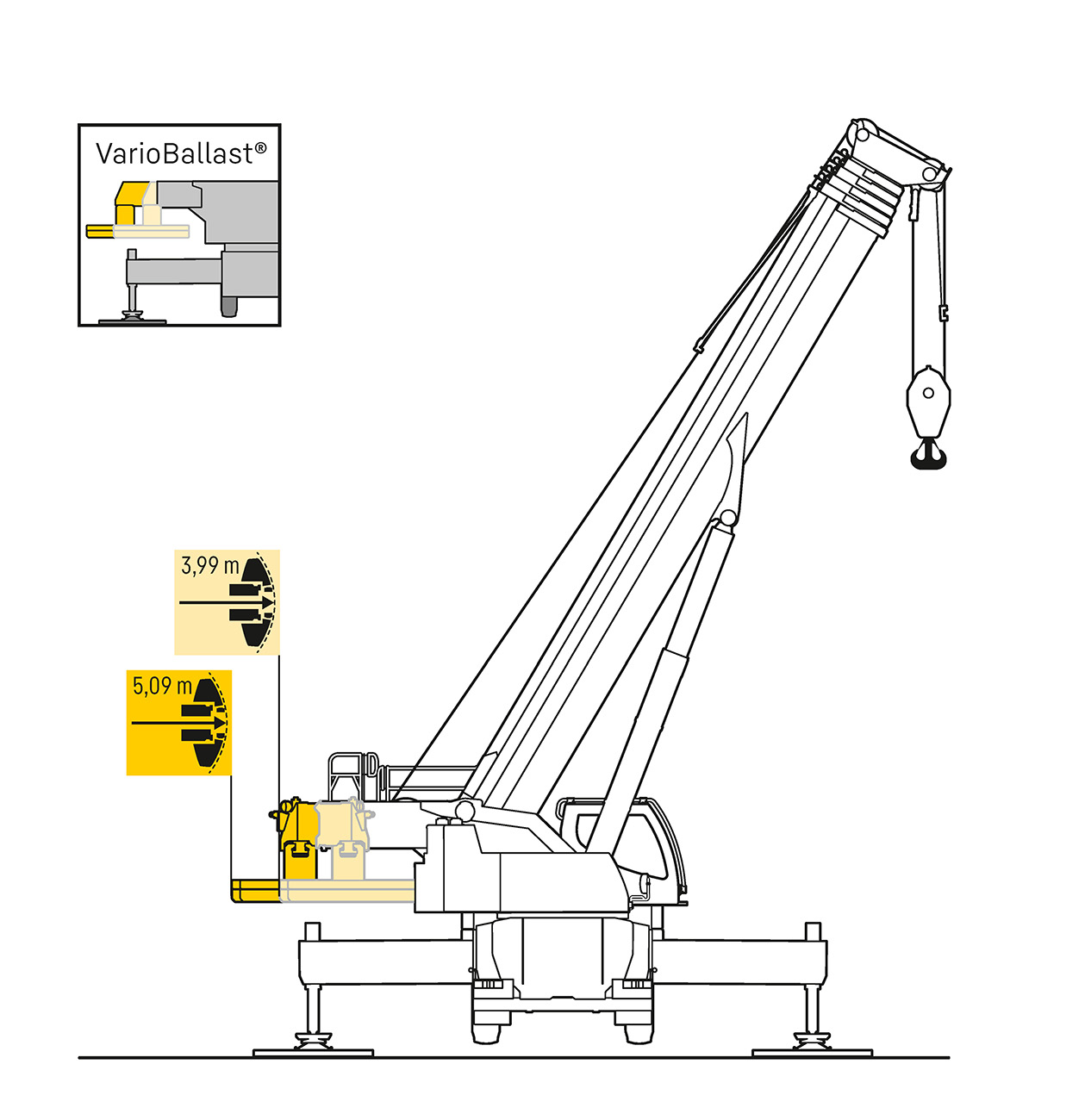

VarioBallast: Counterweight radius

Technology

ECOmode

ECOmode minimises both fuel consumption and noise emissions when operating the crane superstructure. The crane operator sets the required working speed using the control lever. The crane control system calculates the perfect engine speed for the diesel engine.

ECOdrive

ECOdrive makes the mobile crane significantly more comfortable and quieter by reducing the engine speed. Faster gearshifting delivers greater dynamic and traction offroad. On the road, the torque from the Liebherr diesel engine is used efficiently to minimise fuel consumption.

Hillstart-Aid

Hillstart-Aid makes starting on gradients easier. Move off safely and easily without rolling backwards.

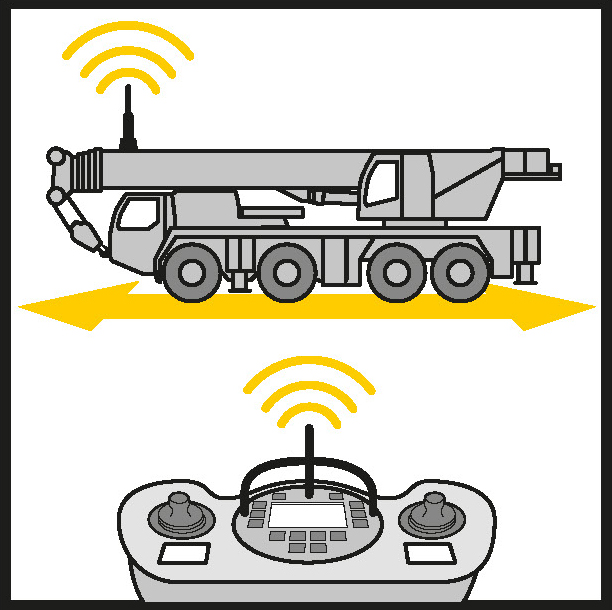

RemoteDrive

The RemoteDrive remote control enables the crane to be controlled from outside the driver’s cabin. This is not only possible during crane operations, but also whilst driving on the site. This delivers greater safety and comfort as the crane operator has a better view of problem areas as he can be right next to them. In other words, the operator can move himself to the areas with difficult access.

LICCON3

The third generation LICCON control system features the same time-tested operation as previous generations and adds a fast data bus, significantly more storage space and greater computing power. LICCON3 cranes are prepared for telematics and fleet management.

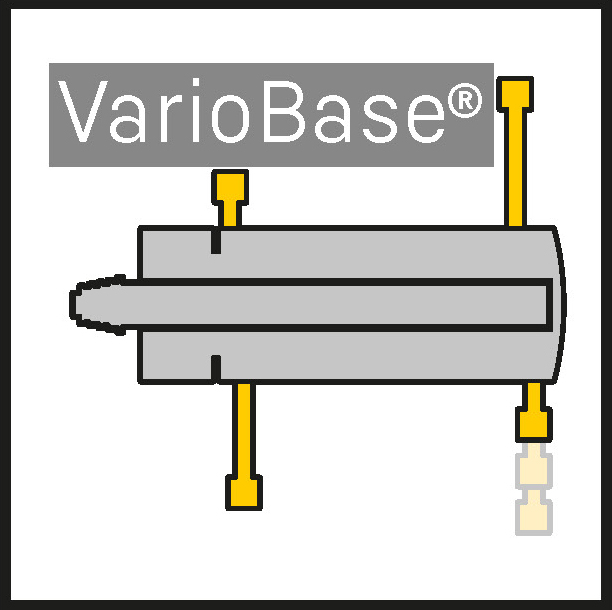

VarioBase®

VarioBase makes the crane’s support system variable. It enables each outrigger to be extended to a different length. This enhances safety – particularly in constricted spaces. And what's more, the crane’s lifting capacities are significantly increased, particularly over the outriggers and depending on the configuration.

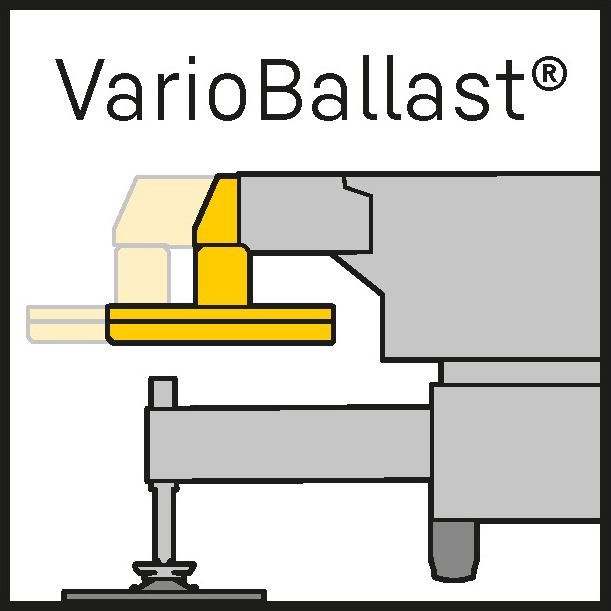

VarioBallast® (mechanical)

Mechanically slewing ballasting cylinders enable the ballast radius to be changed quickly to two different settings. The smaller radius is used in constricted conditions whilst the larger one is used if a higher lifting capacity is required. This significantly increases the crane’s flexibility.

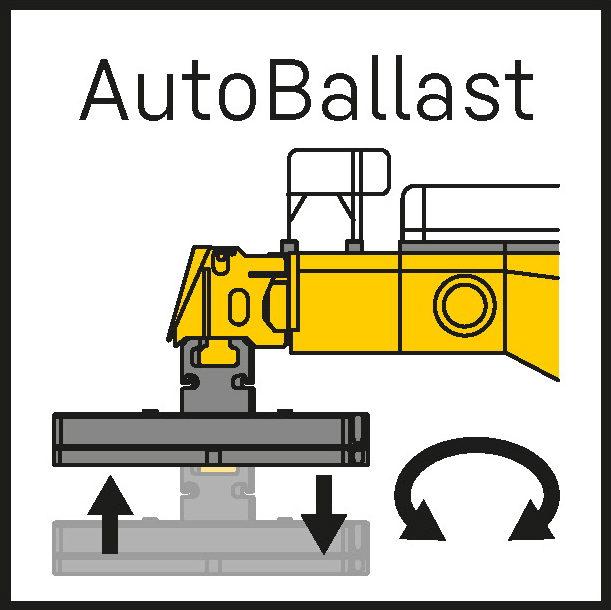

AutoBallast

The AutoBallast function completes the ballasting process automatically. All the steps are carried out after the button has been pressed just once.

WindSpeed load charts

Increased flexibility and safety by using lifting capacity tables with different maximum wind speeds.

HVO ready

Up to 90 % lower CO2 emissions in action.