Apprentices build mini gantry loader all by themselves

As part of an interdisciplinary training project, apprentices at Liebherr- Verzahntechnik GmbH have single-handedly designed, built and programmed a small-scale gantry loader. The aim of the task was to create a functional model, which replicated real processes in automation systems and could also be used as a practical learning object and for demonstrations. This was largely achieved by a project team of apprentices and dual-program students working autonomously.

It all began with the automation software department requesting that the apprenticeship program take a more product related and practice oriented approach. Following a positive result from a similar project, the construction of a small-scale gear cutting machine, it was now time to produce a practical model in the automation division. The miniature gantry loader is now available as a simplified, but fully functional model.

It comprises an H-carriage with two Z-axes for vertical loading and unloading, an X-axis for the travel range, two rotating C-axes and a gripping function. The system is enhanced by infeed and outfeed conveyors as well as two miniature gear cutting machines to simulate a complete material flow. “Our goal was to set our apprentices a practical, product related task, which replicates the essential processes of real automation systems on a smaller scale,” explains Michael Wölfle, Training Instructor for Electrical Engineering.

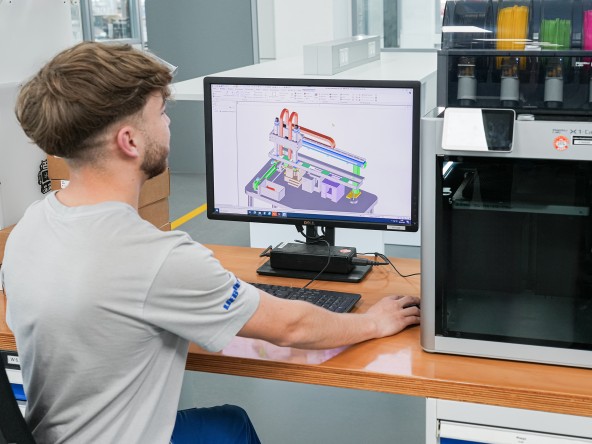

From CAD drawing ...

Motivated, interdisciplinary apprentice team

The project was primarily aimed at apprentices and dualprogram students in electrical engineering with the aim of teaching them basic automation programming in a practical setting. An interdisciplinary team of apprentices in electrical engineering, industrial mechanics and technical product design in their third year, and dual-program students in machine design were responsible for the design and implementation. The training instructors acted as learning coaches, overseeing the project, but only specifying the framework and basic requirements in technology, mechanics and software.

Project planning, execution and specific decisions were left largely to the apprentices. They continuously developed the project through regular meetings. Sophia Steidle, Apprentice in Industrial Mechanics, says: “Every week we agreed on our goals together, assigned tasks and coordinated implementation ourselves. We only asked our training instructions when we were really stuck. It was super fun to be able to work so independently!” Michael Wölfle adds: “We deliberately gave our apprentices a large degree of autonomy, and it was amazing to observe how creatively and enthusiastically they used that opportunity.” Most of the necessary components, like steel and aluminum profiles were produced internally with many parts also being created on the 3D printers in the training center. This kept the number of purchased parts needed to a minimum.

… to finished gantry loader: final touches

Modular learning, fun design

Claudius Kühn, Software Developer in the Automation Department, prepared the learning program. It is a modular design, enabling apprentices to program individual software functions independently. The design allows users to acquire knowledge on a step-by-step basis, complemented by a points system with different difficulty levels.

Claudius Kühn explains: “We wondered how we could design engaging tasks and deliberately integrated ‘gamification’ elements.” Apprentices navigate using a digital tree diagram of tasks with color-coded compulsory and optional tasks. By completing each successive level, they progress their learning in a structured manner. “This way they not only acquire program knowledge, but also learn how our products and systems work through fun tasks,” Kühn elaborates. A knowledge base with a document collection serves provides internal reference material, produced and curated by the apprentices themselves, which will allow future generations of apprentices to benefit from the system.

Understanding the big picture close up

As well as the technical challenges, the apprentices particularly emphasize the fruitful collaboration. “Whenever we needed help, we just had to ask,” says Sophia Steidle. Electrical engineering apprentice Daniel Greif adds: “The most exciting part was getting to grips with the tasks, particularly when they got tricky or didn’t all go according to plan.” Both particularly enjoyed one aspect: “We were in control of almost everything. This helped us understand on a small scale how everything works on a large scale.”

Application-based learning with long-term benefits

With the miniature gantry loader, there is a versatile model available now, which can support internal learning and be presented at trade fairs. The training project has facilitated a practical approach to mechanics, design and programming as well as enhanced autonomous working within the training courses.