Liebherr-Components Newsletter

Edition 3/2025

How do you repair your hydraulic cylinders?

Upgrade to the LiCYB stationary assembly bench not only to ensure safe handling and efficient repairs, but also to qualify as a Liebherr-certified service workshop. Are you ready to take your cylinder repairs to the next level?

Sign up now!

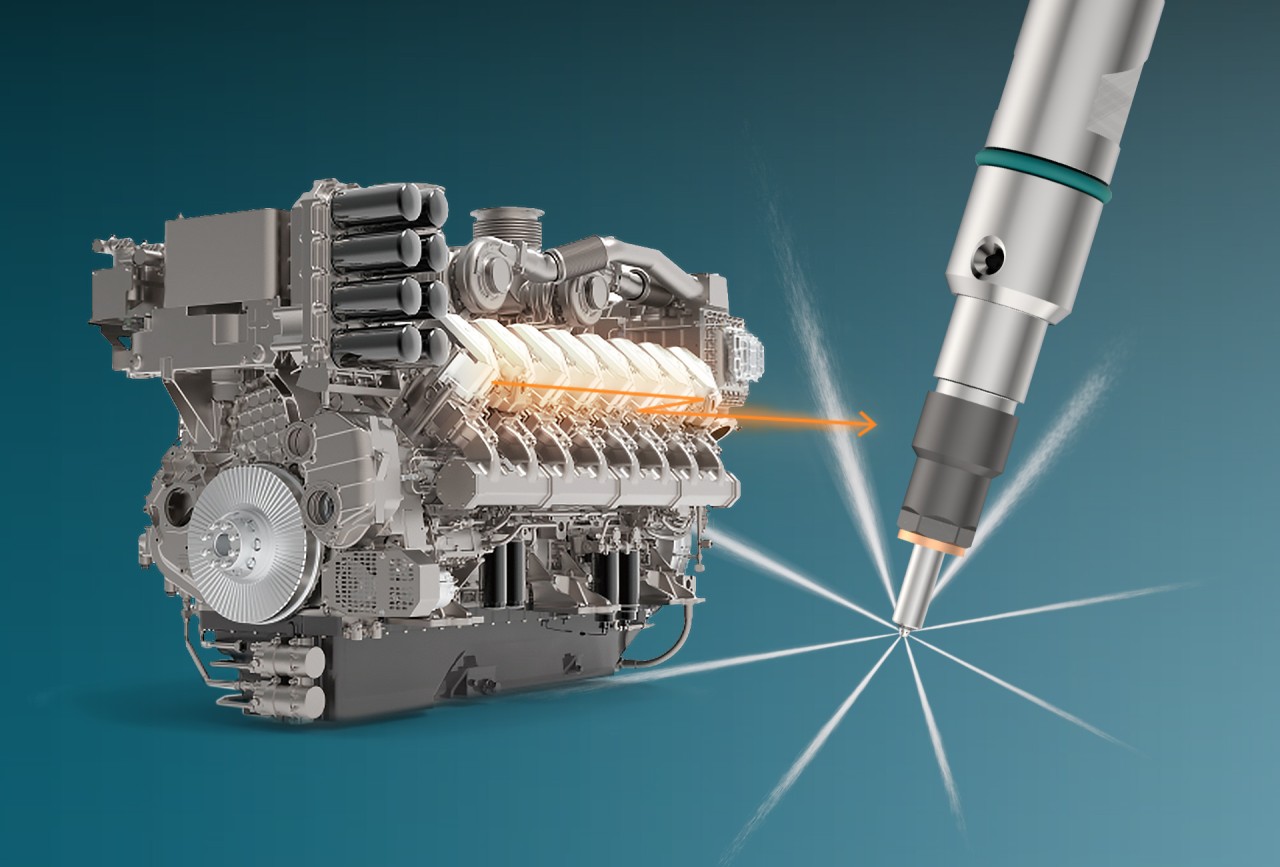

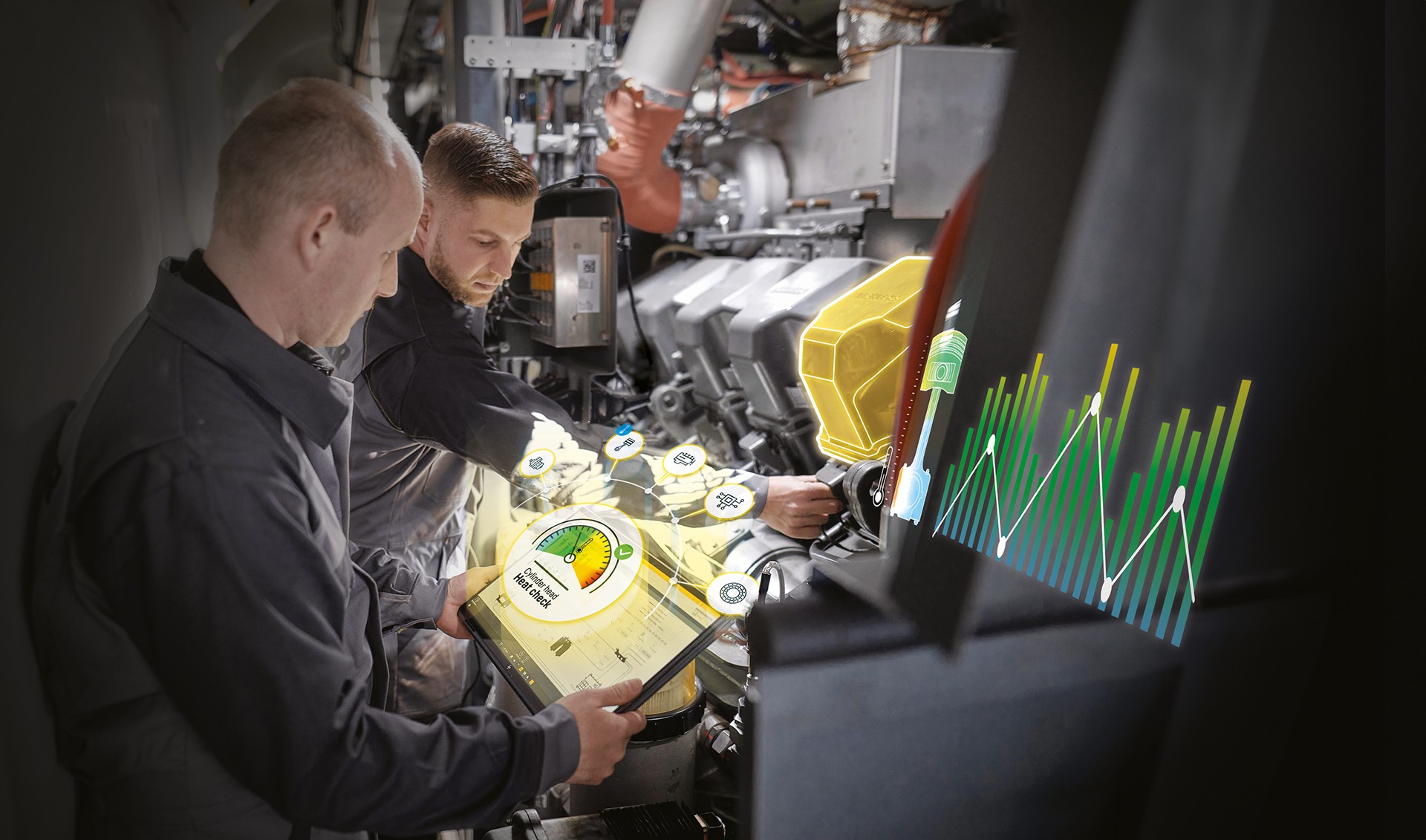

Stay up-to-date with our latest product highlights and innovative technologies.