Cost-effective optimization of tooth flanks

By advancing twist-free generating grinding, Liebherr-Verzahntechnik GmbH is elevating efficiency and quality in hard-fine machining to the next level. The machining times when using dressable grinding worms have been reduced to almost the same level as conventional methods – even with asymmetrical gear teeth. At the same time, optimized shift methods enable fine grinding or polishing to be integrated into a single machining step.

Back in 1988, Liebherr made a groundbreaking advancement by patenting twist-free generating grinding with CBN grinding worms. Now it‘s time for the next step: New functionalities and innovative machine kinematics make the process cost-effective, reliable and of high quality, even with dressable grinding worms. Dressing and cycle times are almost on a par with conventional generating grinding methods.

New application areas for twist-free gearing

The optimized process opens up new application fields for twist-free machining: Practical tests show that even complex geometries such as asymmetrical gear teeth can be optimized for maximum load capacity or reduced noise – or both. The new machine kinematics allow significantly freer shift methods that can be flexibly adapted to component requirements. This enables the integration of fine grinding or polishing, resulting in even higher quality. Even the smallest grinding worms can now be used in a cost-effective manner – an advantage for collision-critical gear teeth. Operation via the user-friendly LHGearTec control system is simple and intuitive.

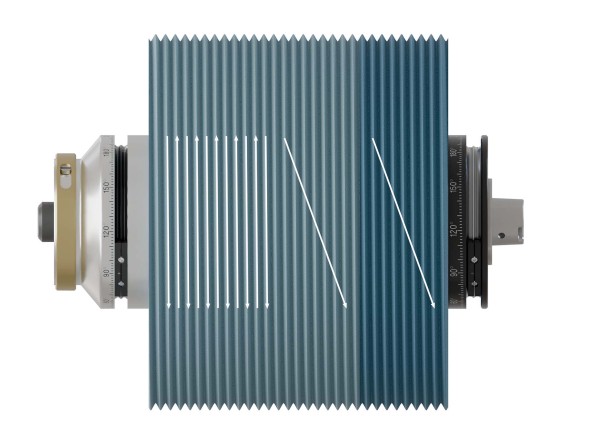

Combined grinding worm segments: Unmodified area for roughing (left) and modified area for finishing (right)

Optimized shift strategies

With optimized shifting, different segments of the grinding worm are used in a targeted manner: By integrating fine grinding or polishing areas or combining modified and unmodified zones (see figure), surface quality and tooth flank geometry can be specifically influenced. According to Fabian Stadelmann, Technology Development Manager at Liebherr-Verzahntechnik GmbH, separating shift length from shift position effectively prevents profile deviations: “The number and length of the diagonal areas can be easily defined using LHGearTec – without affecting the workpiece quality.” The software enables precise control over twist generation, allowing for targeted adjustments (“twist-controlled”).

Targeted tooth flank optimization for cost-effective machining

This offers clear advantages for users: The process enables targeted load and noise optimization – through load-bearing, load-optimized tooth flanks or high surface quality. By combining twist-free generating grinding with fine grinding or polishing as a final step, the strengths of both processes are leveraged, resulting in a significant quality improvement – without economic drawbacks. The use of standard dressers eliminates the need for complex designs for special offset geometries; double-sided dressing is also possible.

Even collision-critical parts such as this workpiece can be machined without interference.

From e-mobility to special gearboxes

The technology is suitable for a wide range of applications – from transmission components for e-mobility to special and heavy-duty transmissions. “In combination with the high rigidity of our machines – often praised by our customers – we offer measurable improvements in efficiency and precision, providing a clear competitive advantage,” summarizes Fabian Stadelmann.