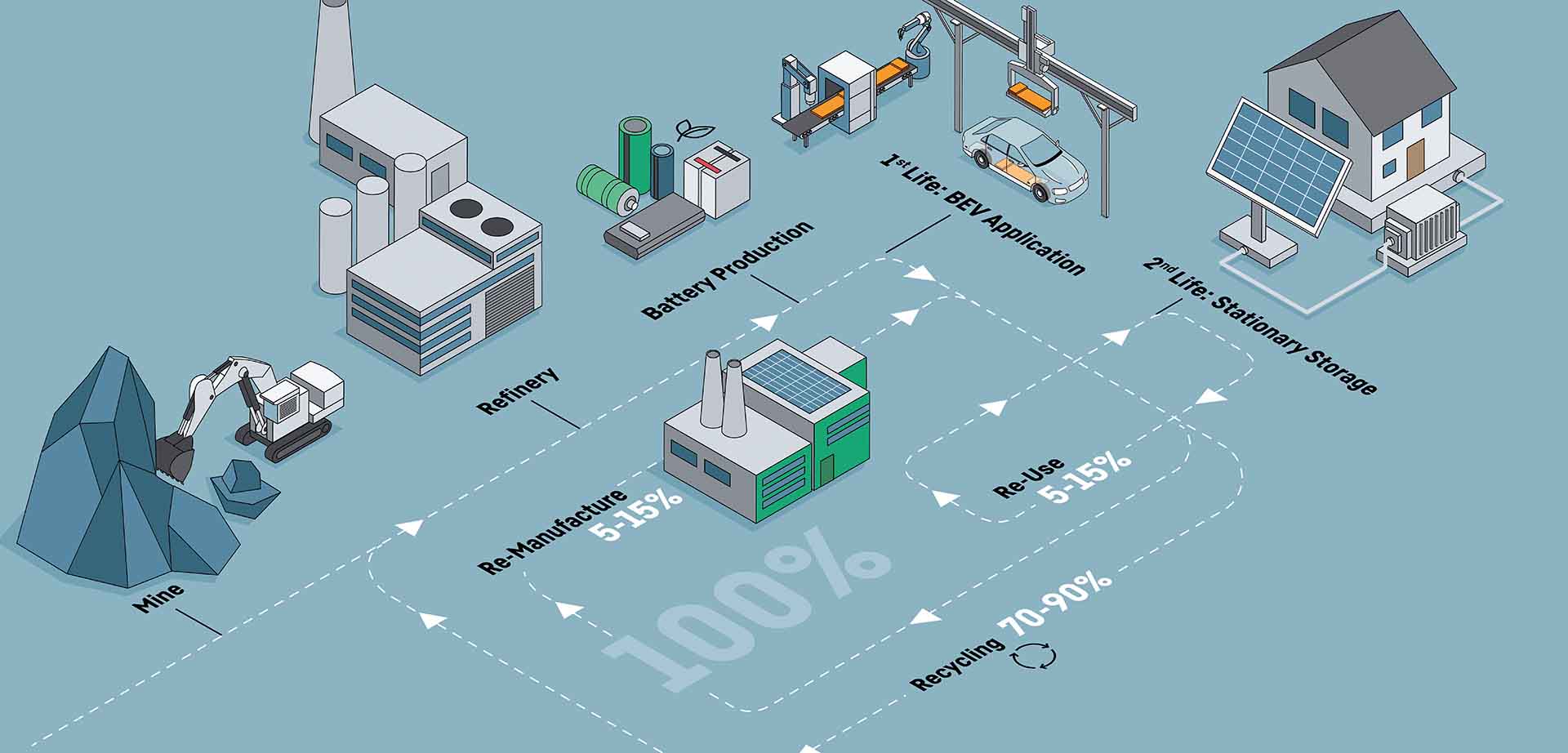

Best of Industry Award for Liebherr automation solution

In 2023, Liebherr-Verzahntechnik GmbH was awarded the Best of Industry Award in the Robotics category. The company received the award for its solution for the automated disassembly of battery packs from electric vehicles.