T 264

Fastest cycle time in the industry

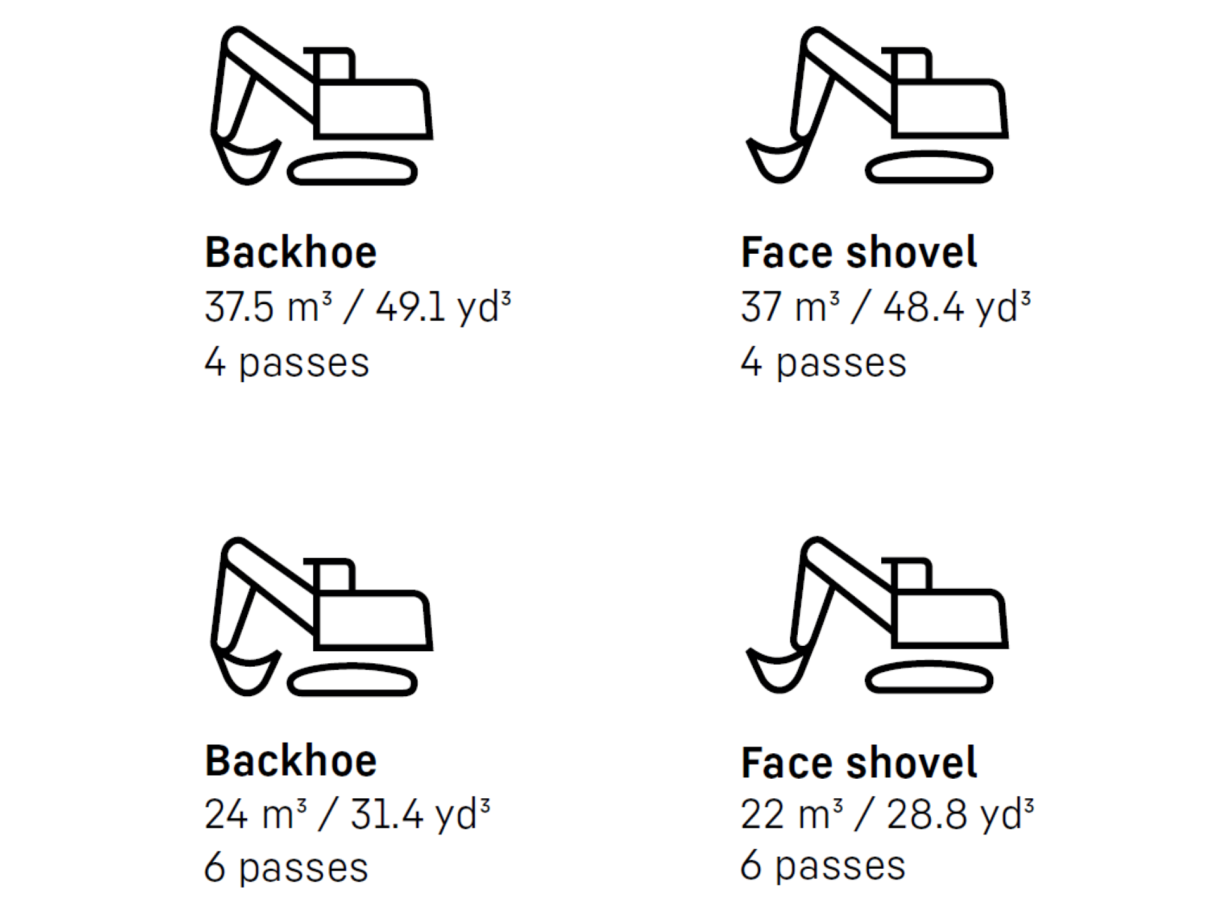

The Liebherr T 264 mining truck is part of the 240-tonne size class and is the perfect pass match for large hydraulic excavators in both face shovel and backhoe configurations as well as wheel loaders in a similar size class. The truck’s unique combination of a powerful engine, an efficient Litronic Plus AC drive system and robust electric wheel motors allows for faster cycle times, making the T 264 exceptionally productive and cost efficient.

Payload class - 240.00 t

240.00 t

Gross vehicle weight (GVW) - 416.00 t

416.00 t

Gross power - 2,013 kW

2,013 kW

T 264 highlights:

Unmatched productivity

Proven quality

Futureproof design

The Liebherr T 264 has exceeded my expectations in terms of its availability and reliability. We’ve been constantly over 90 % availability and have been since the mine opened. The T 264 just excels in overall productivity and efficiency. It carries its load, whether it’s coal or overburden, with no issue at all.

Technical data

| Payload class | 240.00 t |

| Gross vehicle weight (GVW) | 416.00 t |

| Empty vehicle weight (EVW) | 176.00 t |

| Engine model | Cummins QSK 60 |

| Gross power | 2,013 kW |

| Engine model (option A) | Liebherr D9812 |

| Gross power (option A) | 2,013 kW |

| Engine model (option B) | MTU 16V4000 |

| Gross power (option B) | 2,013 kW |

| Emissions (USA/EPA) (option 3) | Tier 4 |

| Drive system | Liebherr Litronic Plus AC drive system with IGBT technology |

| Max speed | 55 km/h |

Downloads

Videos

An Australian customer testimonial about the Liebherr T 264

Machine gallery

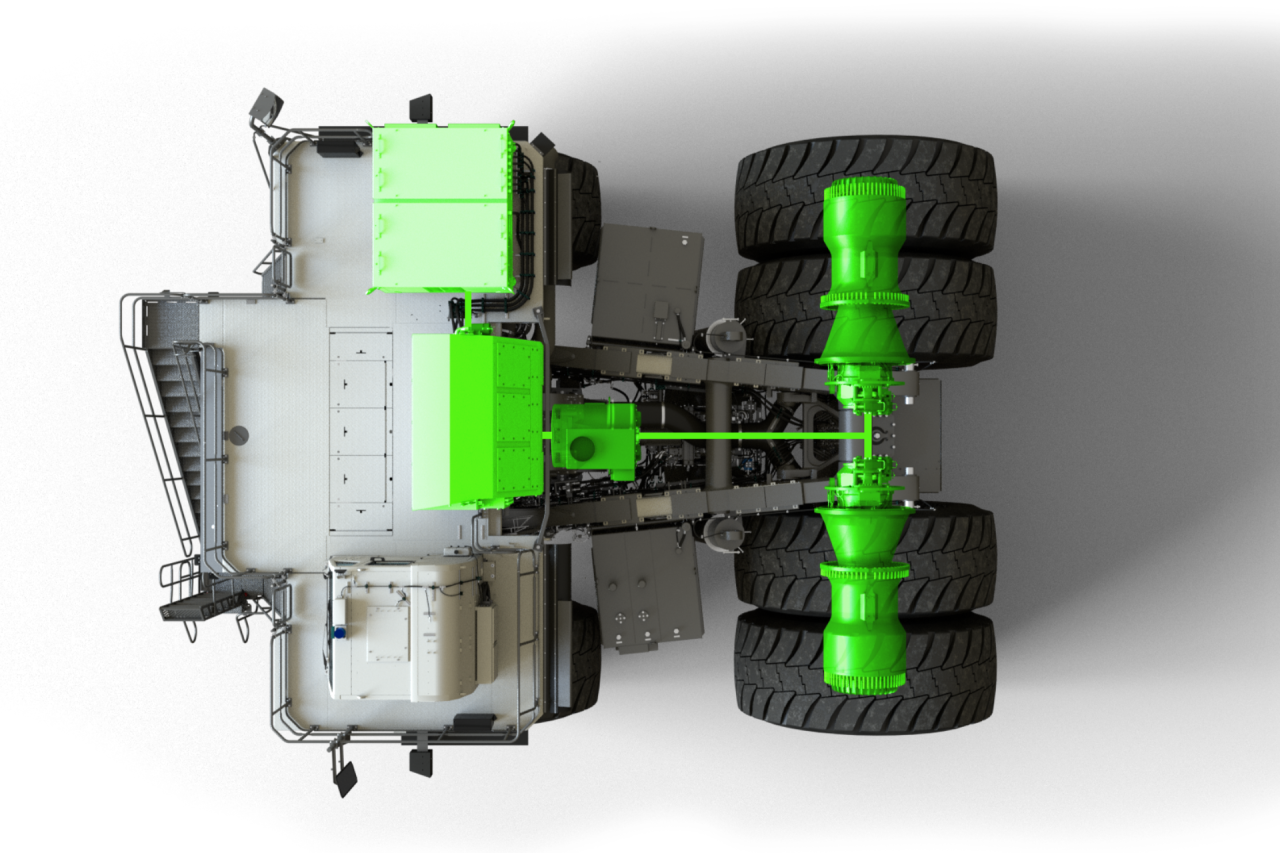

Innovative design and technologies powering the T 264

Truck excavator match*

*Site-specific factors like loose material density, bucket size, fill factors, truck body size and payload capacity will influence pass match. Contact your local Liebherr sales and service company or sales partner for analysis of your site.

The perfect Liebherr pairing

Discover the perfect pairing for the R 9400 and R 9600 excavators with our innovative truck match solution. Explore the seamless synergy between our advanced excavator technology and high-performance mining trucks, setting a new standard for excellence in the industry.