R 9400 G6

Built for when the going gets tough

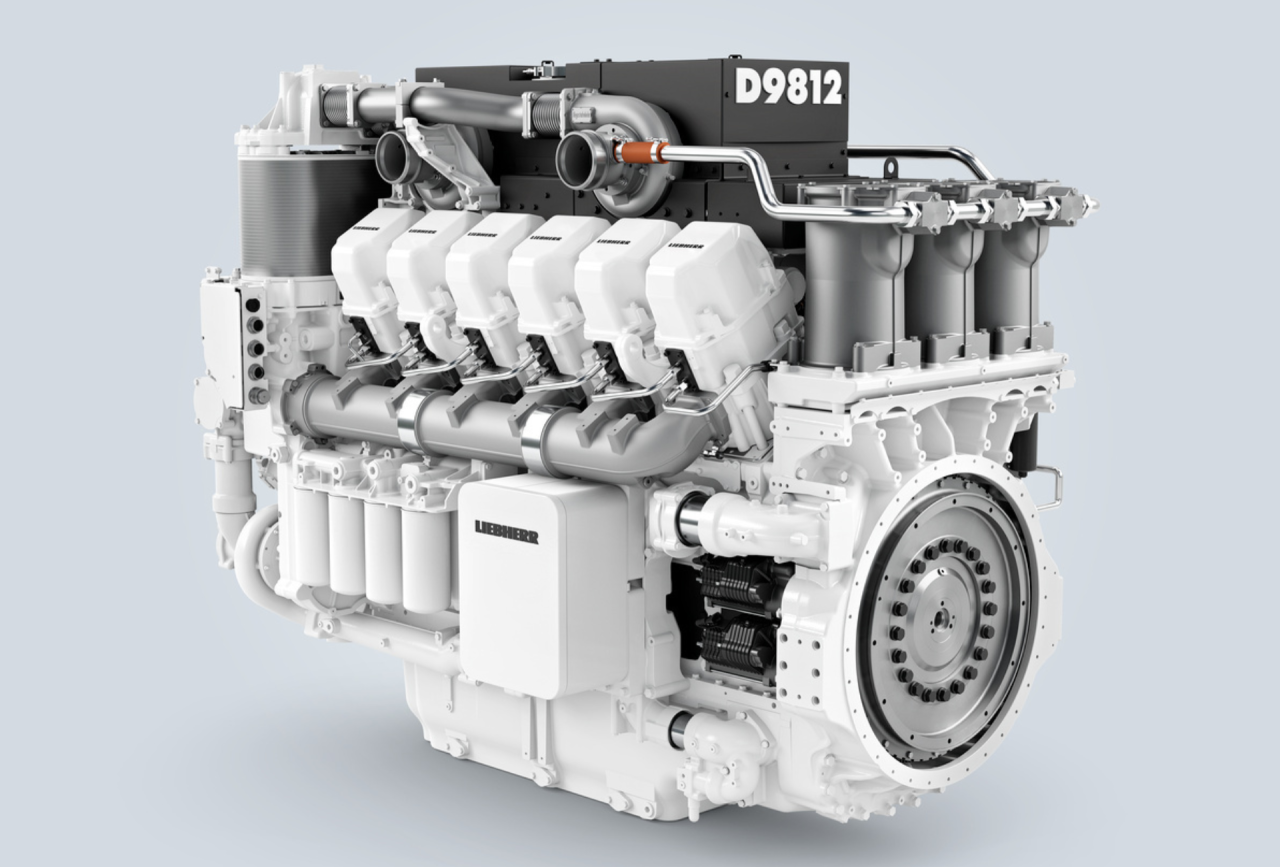

The R 9400 can be relied upon to provide top-notch performance again and again and again. With its class-leading payload capacity and a service life of more than 60,000 operational hours, this powerful piece of digging equipment will be a high-performing and reliable partner for the long term. And with its modular design, the R 9400 can easily be repowered, retrofitted, or upgraded with the technology of the future. Plus, this hydraulic excavator comes equipped with Liebherr’s D9812 V12 powertrain meaning customers only need one point of contact for their maintenance needs, therefore keeping this workhorse of an excavator working harder for longer.

Operating weight with backhoe attachment - 345.50 t

345.50 t

Operating weight with face shovel attachment - 353.00 t

353.00 t

Engine rating at 1800 rpm - 1,250 kW

1,250 kW

Bucket capacity at 1.8 t/m³ - 24.00 m³

24.00 m³

Shovel capacity at 1.8 t/m³ - 22.00 m³

22.00 m³

R 9400 highlights:

Built to last over 60,000 operational hours

9% more payload capacity

One stop shop

We needed to find a machine that would provide better availability than the wheel loader while still matching the 240-tonne truck. Liebherr came to the table with the R 9400. They also took the extra step to develop an optimised bucket for the machine. We’ve actually seen about a 40% gain in our production in the last three months.

| Engine model | Cummins QSK50 |

| Engine rating at 1800 rpm | 1,250 kW |

| Emissions (USA/EPA) | Tier 2 / US EPA Tier 4f / EU Stage V |

| Engine model (option A) | Liebherr D9812 |

| Engine rating at 1800 rpm (option 2) | 1,350 kW |

| Electric motor (option) | Available |

| Attachment and travel drive pump | 4 variable flow axial piston pumps x 751 l/min. @ 320 bar |

| Swing drive pump | 2 reversible swash plate pumps x 390 l/min. @ 350 bar, closed-loop circuit |

| Maximum swing speed | 3.90 rpm |

| Operating weight with backhoe attachment | 345.50 t |

| Bucket capacity at 1.8 t/m³ | 24.00 m³ |

| Bucket capacity at 1,8 t/m³ (High Performance Option) | 24.00 m³ |

| Liebherr GET system for GP/HD/XHD buckets | Z140/Z140/Z140 |

| Max. digging force (ISO 6015) | 965 kN |

| Max. breakout force (ISO 6015) | 1,000 kN |

| Operating weight with face shovel attachment | 353.00 t |

| Shovel capacity at 1.8 t/m³ | 22.00 m³ |

| Liebherr GET system for GP/HD/XHD shovels | Z140/Z140/Z140 |

| Max. crowd force at ground level (ISO 6015) | 1,145 kN |

| Max. crowd force (ISO 6015) | 1,545 kN |

| Max. breakout force for shovel (ISO 6015) | 1,195 kN |

Downloads

Videos

Product video R 9400 United States

Watch Liebherr Bucket Solutions and Ground Engaging Tools!

Cable reel system for a R 9400 E

Machine gallery

Minimise your carbon impact

We develop our mining machines in a modular way so that we can constantly upgrade or retrofit them with alternative drives. Our excavators are no exception to this philosophy. In Australia, for example, we retrofitted an R 9400 diesel excavator produced in 2010 with an electric drivetrain, turning it into an R 9400 E.

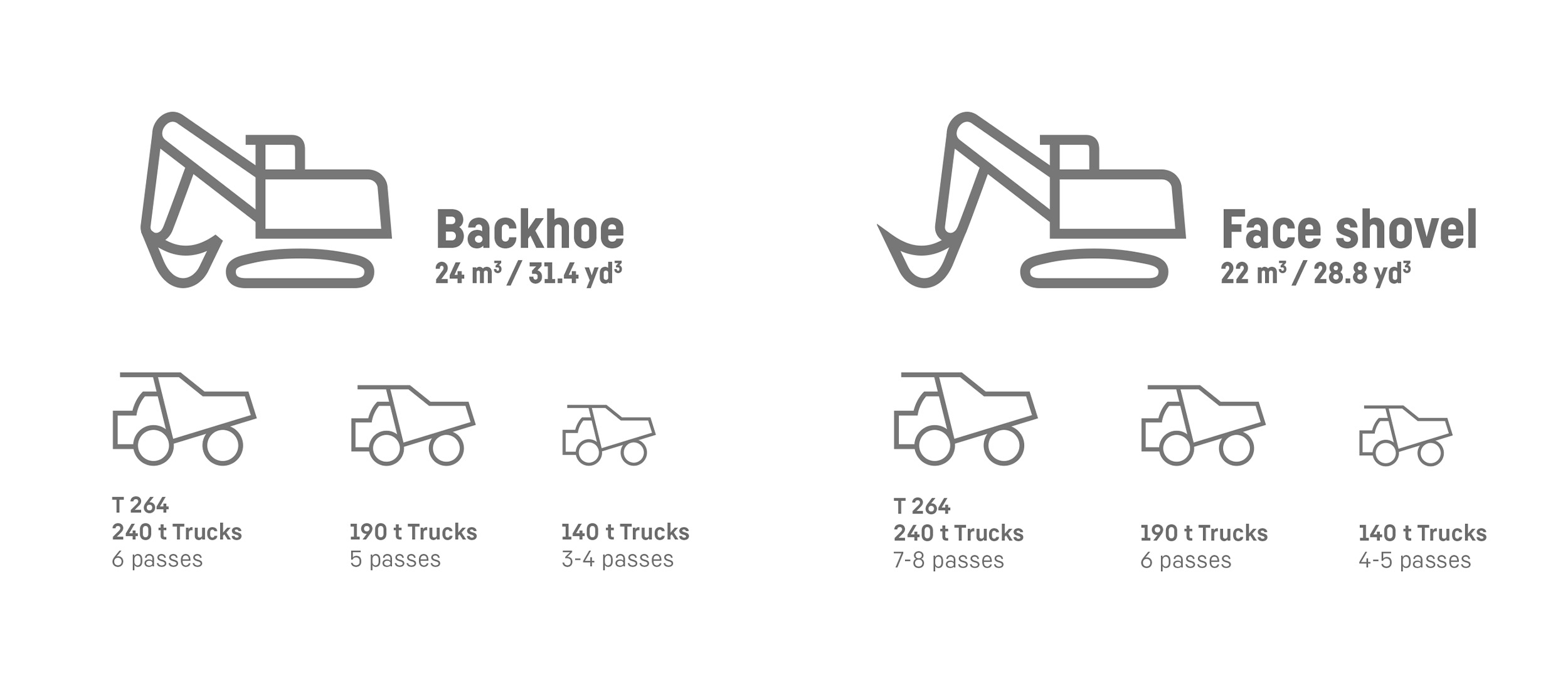

Excavator truck match*

*Site-specific factors like loose material density, bucket size, fill factors, truck body size and payload capacity will influence pass match. Contact your local Liebherr sales and service company or sales partner for analysis of your site.

The perfect Liebherr pairing

Discover the perfect pairing for the R 9400 excavator with our innovative truck match solution. Explore the seamless synergy between our advanced excavator technology and high-performance mining trucks, setting a new standard for excellence in the industry.