As before, ChamferCut is a technology with a great deal of development potential. A new upgrade is now pushing the limits of the impossible.

As before, ChamferCut is a technology with a great deal of development potential. A new upgrade is now pushing the limits of the impossible.

Half a century of Liebherr-Verzahntechnik GmbH means 50 years of commitment to the machinery and plant engineering industry. Gear technology originated in the technology of the revolving tower crane. Hans Liebherr wanted to buy a gear hobbing machine for gear manufacturing, but could not find what he wanted – so he simply built it himself. It’s a typical Liebherr story, since many sectors in the company group have emerged in this or in a similar way. Taking things into one’s own hands: an attitude that can still be found at Liebherr today.

Bauer Gear Motor operates two new LC 180 gear hobbing machines at its facility in Slovakia, producing gearing for all facilities. These machines are characterised by their operational versatility, given that they are used to produce around 180 different components in a very wide range of different sizes.

“The fire pump is the heart of every fire truck”, explains Michael Schöftner, Head of Mechanical Production at Rosenbauer International AG, the global leader for fire service equipment. The equipment has to withstand enormous loads in cases of operation. Rosenbauer relies on an automation solution for pump manufacturing from Liebherr. The rotary loading system RLS 800 from the Kempten-based automation experts has been deployed in Leonding near Linz for around two years now.

E-cars are very demanding in terms of gear quality. Great Taiwan Gear relies on Liebherr machines.

How do you get closer to the customer? For Liebherr the answer is simple: by increasing presence locally.

Quality management has a special place at Liebherr, it protects the core of the brand. The following is an overview of the processes necessary for quality assurance provided by Christof Porsche.

The first PHS 1500 Pro is at Herborner Pumpentechnik. Following an extension and machine change, the third expansion will start soon.

It begins with an idea. But designers often have a long way to go before a perfect workpiece is made using a suitable manufacturing process. It is good that reliable partners such as Liebherr participate and share their experiences.

Weishaupt, headquartered in the Upper Swabian town of Schwendi, is a leading provider of burners, heat pumps, heating and condensing-boiler systems, energy recovery solutions, and facility automation. Since mid-2016 Weishaupt’s new burner casing production facility has operated using an automation solution provided by Liebherr-Verzahntechnik GmbH.

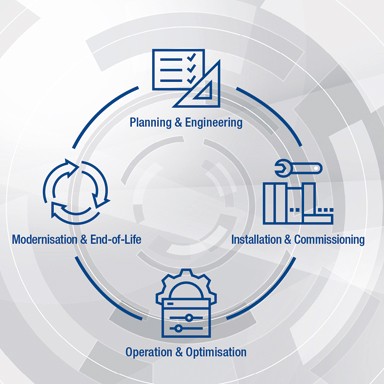

With the newly formed “Industrial Services” department, Liebherr-Verzahntechnik GmbH is reimagining the service ethos.

Due to the high demand, the automation division of Liebherr-Verzahntechnik GmbH has restructured the area of robotics and made it a separate department. The editors of Liebherr Magazine went to visit and had a look around.