T 274

Where innovation meets a tried-and-tested design

The T 274 follows the same base design as the T 284, benefitting from its decades of field experience. Operators and technicians can expect to experience first-class comfort and safety while driving and servicing this truck. A wide range of options are available, not only providing maximum productivity even in the harshest conditions, but also catering to the evolving requirements of customers and mine sites. This new 305 tonne truck can be fitted with the Liebherr Trolley Assist System, a significant step towards zero emission mining.

Payload class - 305.00 t

305.00 t

Gross vehicle weight (GVW) - 528.00 t

528.00 t

Gross power - 2,720 kW

2,720 kW

T 274 highlights:

Proven experience

Application flexibility

Powerhouse engine

Technical data

| Payload class | 305.00 t |

| Gross vehicle weight (GVW) | 528.00 t |

| Empty vehicle weight (EVW) | 223.00 t |

| Engine model | MTU 20V4000 C22 |

| Gross power | 2,720 kW |

| Engine model (option A) | Liebherr D9816 |

| Gross power (option A) | 2,700 kW |

| Engine model (option B) | MTU 16V4000 C65 |

| Gross power (option B) | 2,400 kW |

| Emissions (USA/EPA) (option 3) | Tier 4 |

| Drive system | Liebherr Litronic Plus AC drive system with IGBT technology |

| Max speed | 53 km/h |

| Tire sizes - standard | 53/80 R63 |

Downloads

Machine gallery

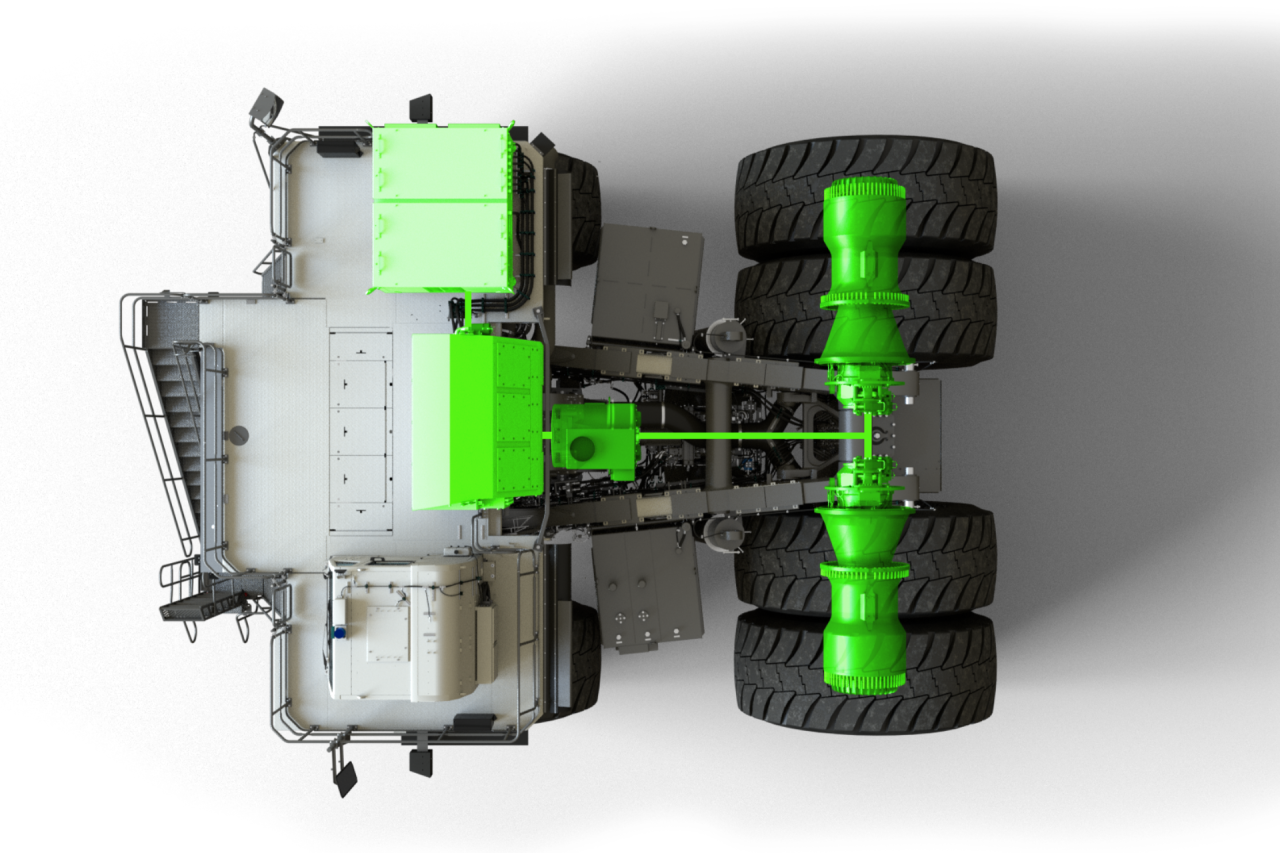

Innovative design and technologies powering the T 274

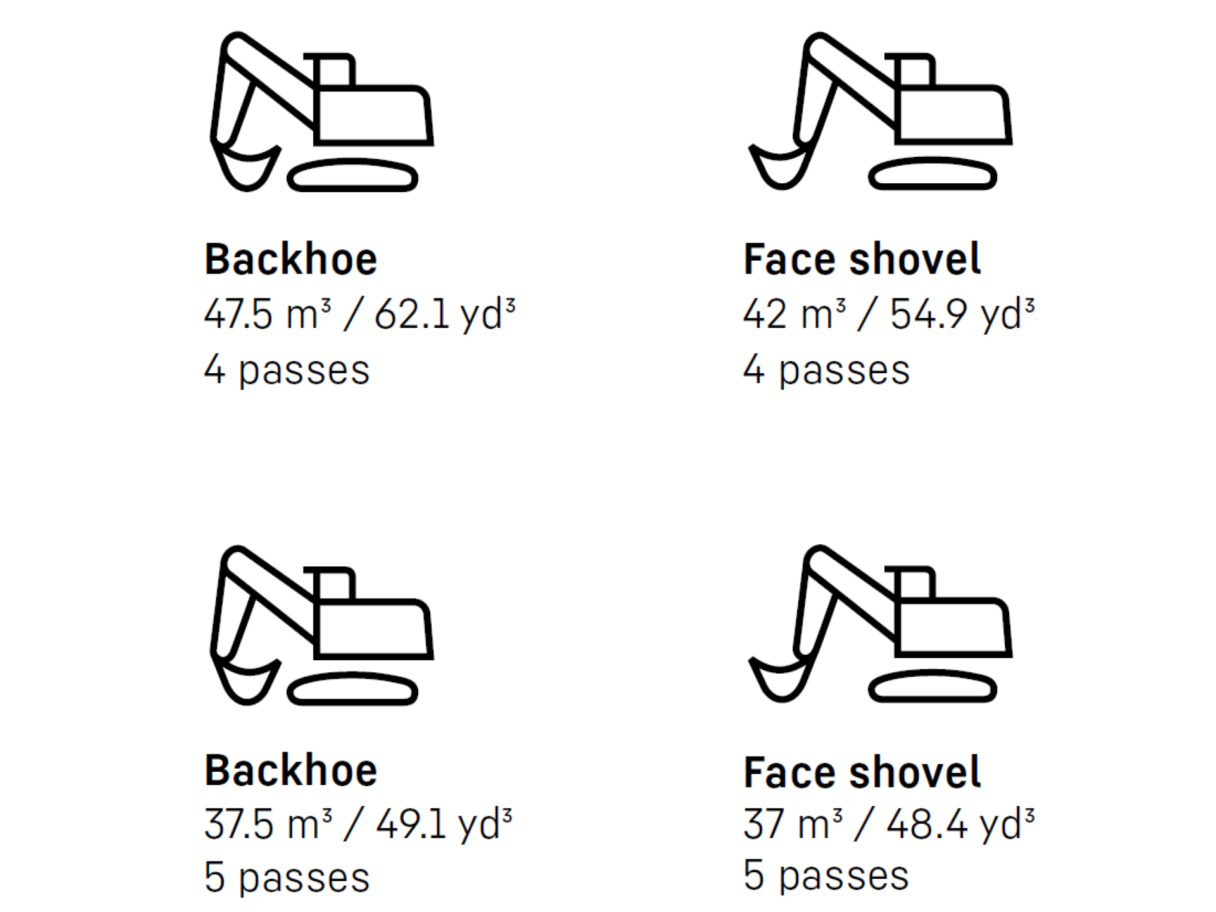

Truck excavator match*

*Site-specific factors like loose material density, bucket size, fill factors, truck body size and payload capacity will influence pass match. Contact your local Liebherr sales and service company or sales partner for analysis of your site.

The perfect Liebherr pairing

The T 274 is the powerhouse of the 305-tonne class and is a perfect pass match for R 9600 and R 9800 excavators. This mining truck is designed to thrive in a wide range of applications and provides maximum productivity, even in the harshest conditions. It especially thrives in large deep-pit applications where its high power-to-weight ratio results in fast cycle times.