LS 80 - 280 F/E

Precision. Speed. Quality.

Space saving

User-friendly

Top quality

Versatile

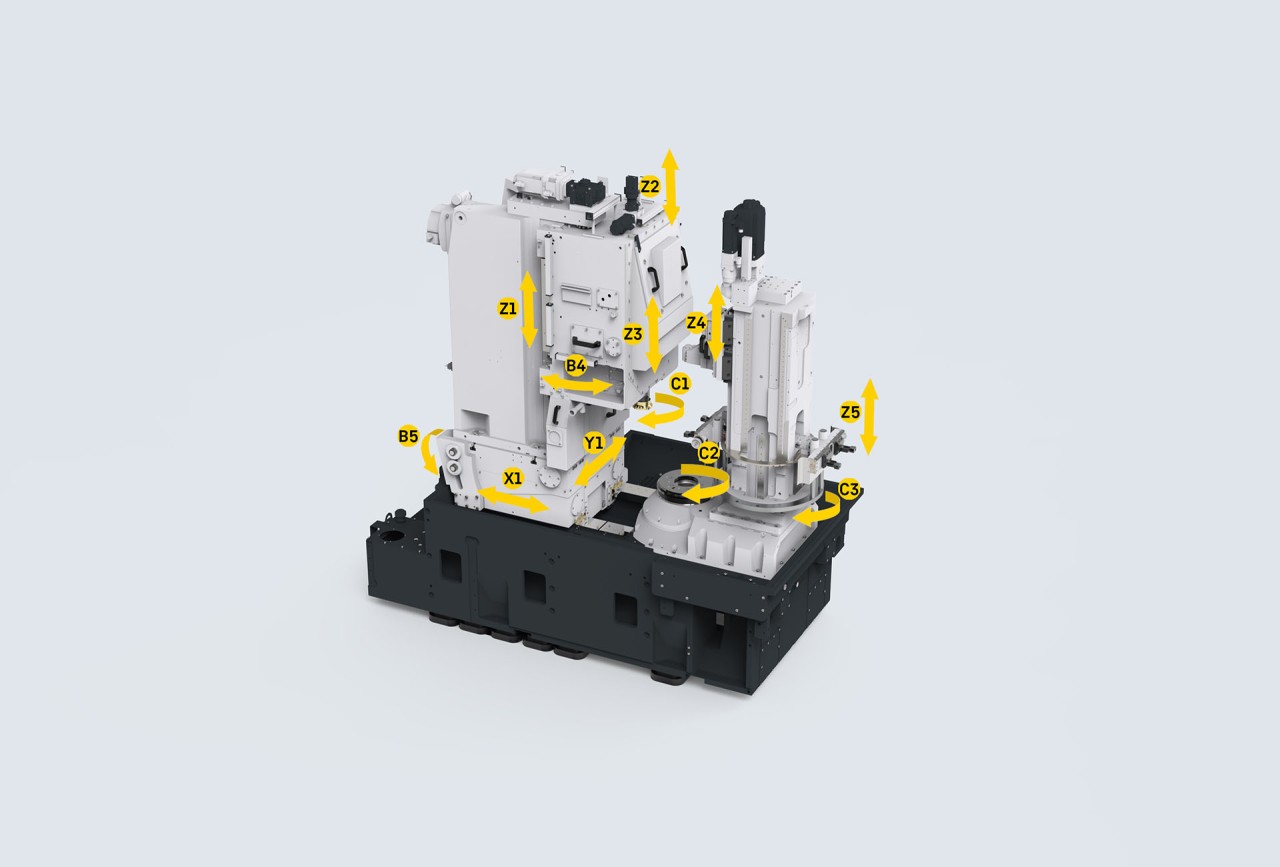

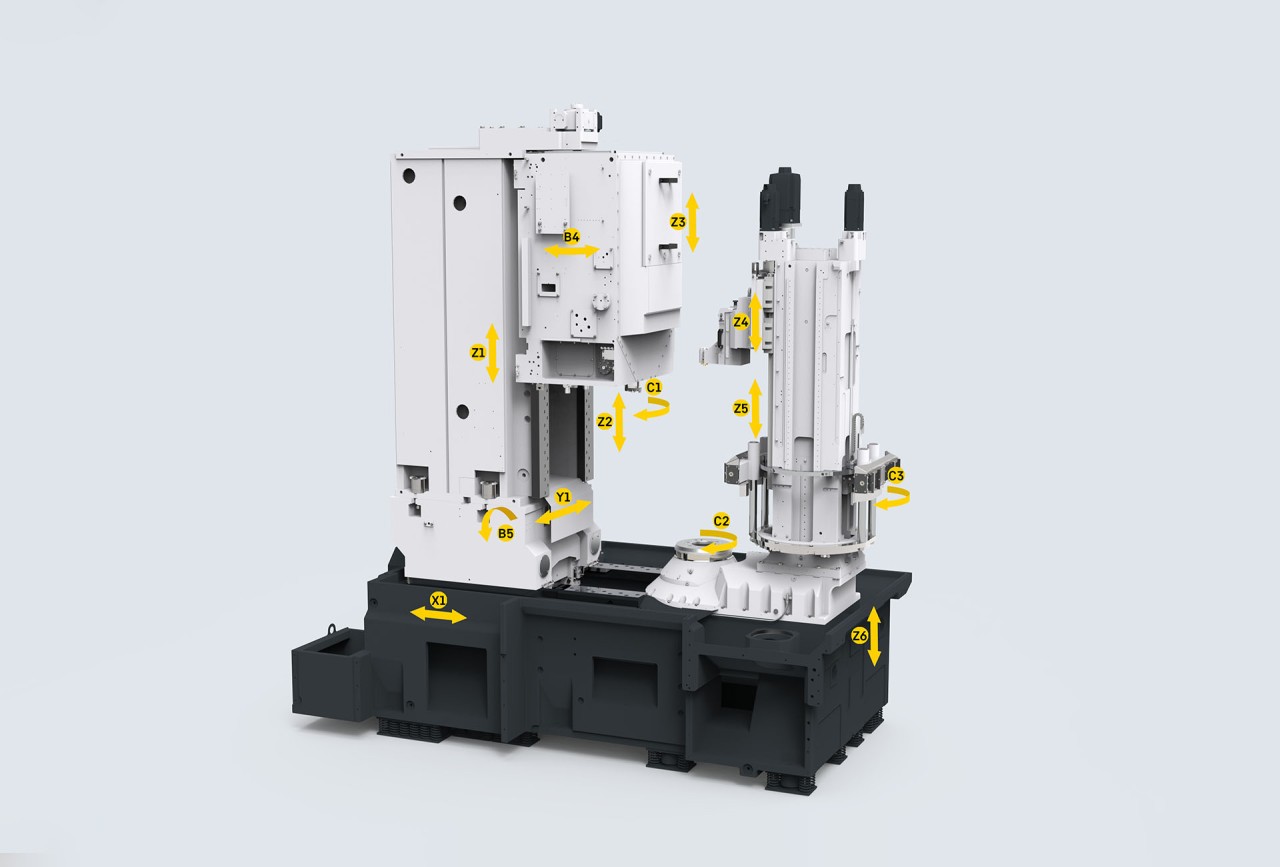

Machine design

Our Liebherr gear shaping machines are optimally adapted to the diverse requirements of universal applications. Their axially movable shaping head slide enables extremely efficient production of very diverse components with minimum setup time. The variable machining position enables optimum alignment of the shaping head depending on the clamping fixture used. Thanks to the variable machining positions, multiple gearings can be machined within a single clamping fixture.

Our machine concept is suitable for wet machining as well as dry machining.

For economical and efficient production, we recommend the ringloader concept, which enables fast loading and unloading of workpieces. In addition, Liebherr offers various external automation systems such as a plastic chain conveyor and chain conveyor storage mounted directly on the machine.

Quick summary of the highlights of the gear shaping machines

- Vertically movable shaping head

- SK 40 tool interface

- Small footprint

- Available with mechanical helical guide (SH70M) or electronic helical guide (SH70E)

- Highly efficient automation system

- Optional: twin-track cam system, swiveling machine column, automatic stroke length adjustment

Conclusion: The perfect machine for small and medium-sized workpieces.

Focus on technological highlights

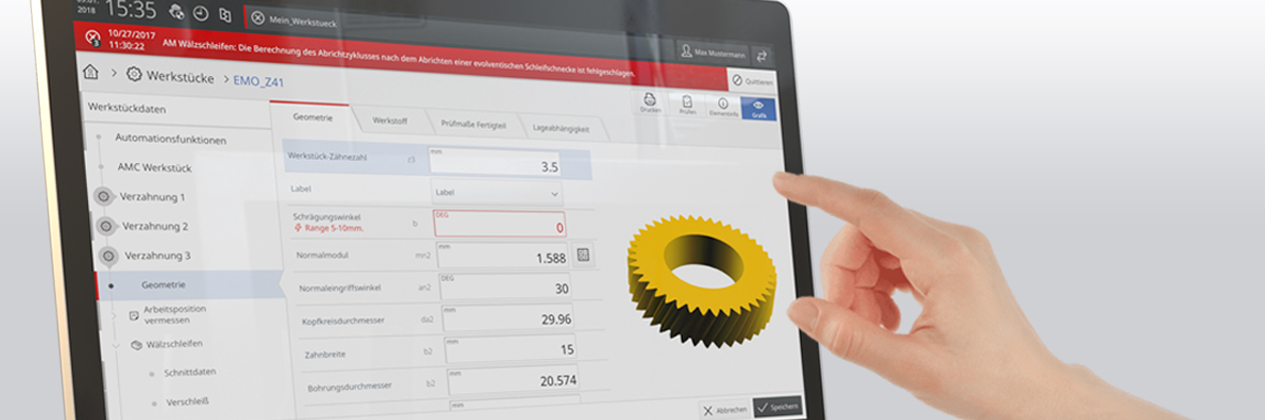

Maximum user-friendliness

Technical data

| Module | 3.00 - 5.00 mm |

| Workpiece diameter | 80 - 280 mm |

Variants

| Variants | LS 80 - 280 | LS 180 - 280 F | LS 180 - 280 E |

|---|---|---|---|

| Module (mm) | 3.00 / 5.00 | 5.00 | 5.00 |

| Workpiece diameter (mm) | 80 / 180 / 280 | 180 / 280 | 180 / 280 |

| Stroke length (mm) | 30 / 55 | 70 | 70 |

| Max. stroke rate (DH/min) | 3,000 / 1,500 | 1,500 | 1,500 |