Monitoring the energy consumption of machines and workpieces

LHEnergyInfo: Quantifying sustainability

Monitoring the energy consumption of machines and workpieces

LHEnergyInfo: Quantifying sustainability

Monitoring the energy consumption of machines and workpieces

LHEnergyInfo: Quantifying sustainability

Monitoring the energy consumption of machines and workpieces

LHEnergyInfo: Quantifying sustainability

The new LHEnergyInfo app from Liebherr-Verzahntechnik GmbH measures and displays energy consumption in production in detail and in real time. As an integral part of the LHWebPlatform, it marks another step forward in the company‘s digitalization strategy.

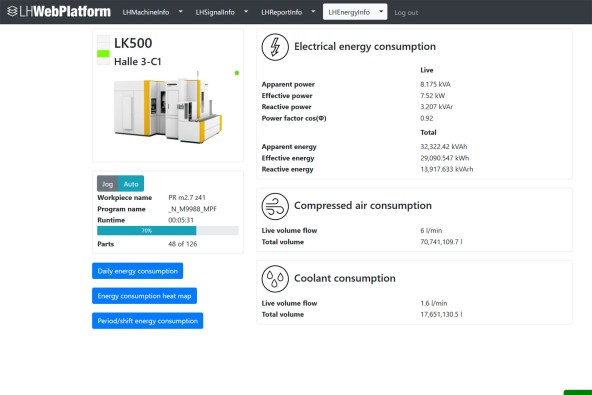

Sustainable production is becoming increasingly important in machining. LHEnergyInfo evaluates energy consumption data in production in a targeted manner – clearly presented and accessible at any time in the LHWebPlatform. Electricity, compressed air, and cooling lubricant consumption is recorded per machine, per shift, per day, and even per workpiece.

All current consumption data at a glance with LHEnergyInfo

Transparent energy consumption

“Sustainability is firmly anchored in our corporate strategy. With LHEnergyInfo, we provide our customers with complete transparency about all energy consumption – including previously overlooked secondary consumption, such as standby mode or when the control voltage is active overnight,” explains Florian Schuon, Head of Digital Solutions. The app highlights individual process parameters and pinpoints potential savings.

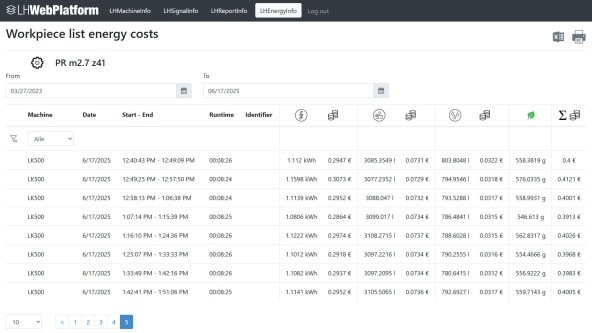

Detailed overview of costs and energy consumption for each individual workpiece

Data for each individual workpiece

LHEnergyInfo is unique in that it can break down energy consumption for individual workpieces. The app helps companies provide CO₂ equivalent certification for their products, such as components like gears within complex assemblies.

Cost efficiency and sustainability

In addition to detailed evaluations, a heat map provides a quick and intuitive overview of energy flows and peak loads. This allows specific starting points for optimizing processes and reducing energy costs to be identified. In addition, the system supports compliance with legal requirements and may even be eligible for funding under Industry 5.0 initiatives.