LTM 1150-5.4

Mobile crane

LTM 1150-5.4 – The jewel in your fleet.

The LTM 1150-5.4 is the latest generation of our successful 150-tonne crane. The tried-and-tested LTM 1150-5.3 has been further developed with our new LICCON3 crane control system. The 5-axle crane now not only shines with state-of-the-art technology, but also with the typical LICCON3, trend-setting crane design. In addition, the all-terrain crane now has numerous new driver assistance systems to increase driving safety on the road.

Max. load capacity - 150 t

150 t

Telescopic boom - 66 m

66 m

Max. hoist height - 92 m

92 m

Max. radius - 72 m

72 m

Number of axles - 5

5

LICCON3:

Economical design:

Makes a great deal possible:

Off-road assistance:

Efficient:

Hook block can be ballasted:

Photo gallery

Technical data

| Max. load capacity | 150 t |

| at radius | 3.00 m |

| Telescopic boom from | 12.30 m |

| Telescopic boom up to | 66.00 m |

| Lattice jib from | 2.90 m |

| Lattice jib up to | 26.00 m |

| Drive engine/make | Liebherr |

| Drive engine | 6-Zylinder-Diesel |

| Drive engine/power | 400 kW |

| Number of axles | 5 |

| Drive/Steering standard | 10 x 6 x 10 |

| Drive/Steering option | 10 x 8 x 10 |

| Driving speed | 85.00 km/h |

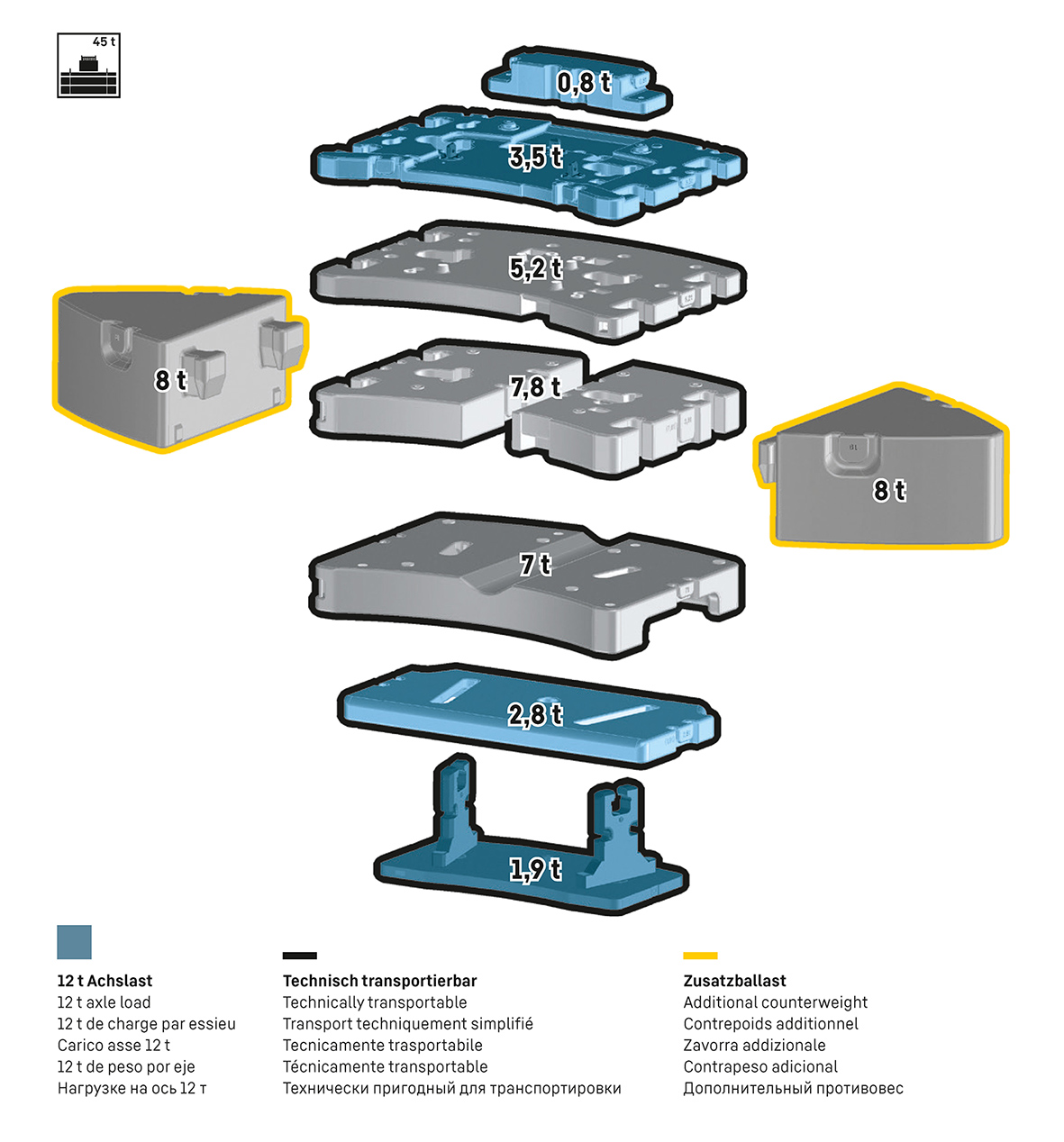

| Total ballast | 45.00 t |

Downloads

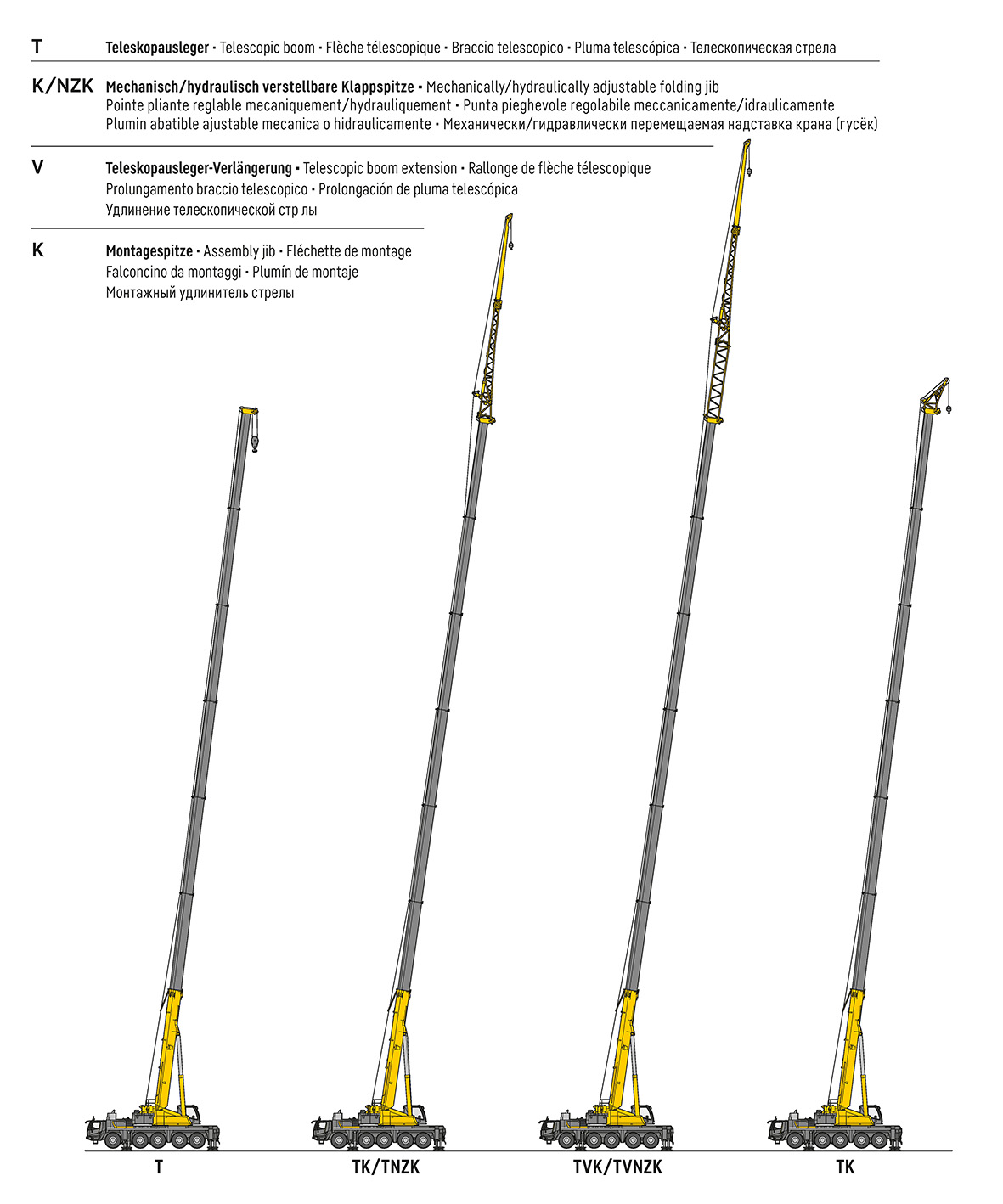

Boom/jib combinations

Boom/jib combinations

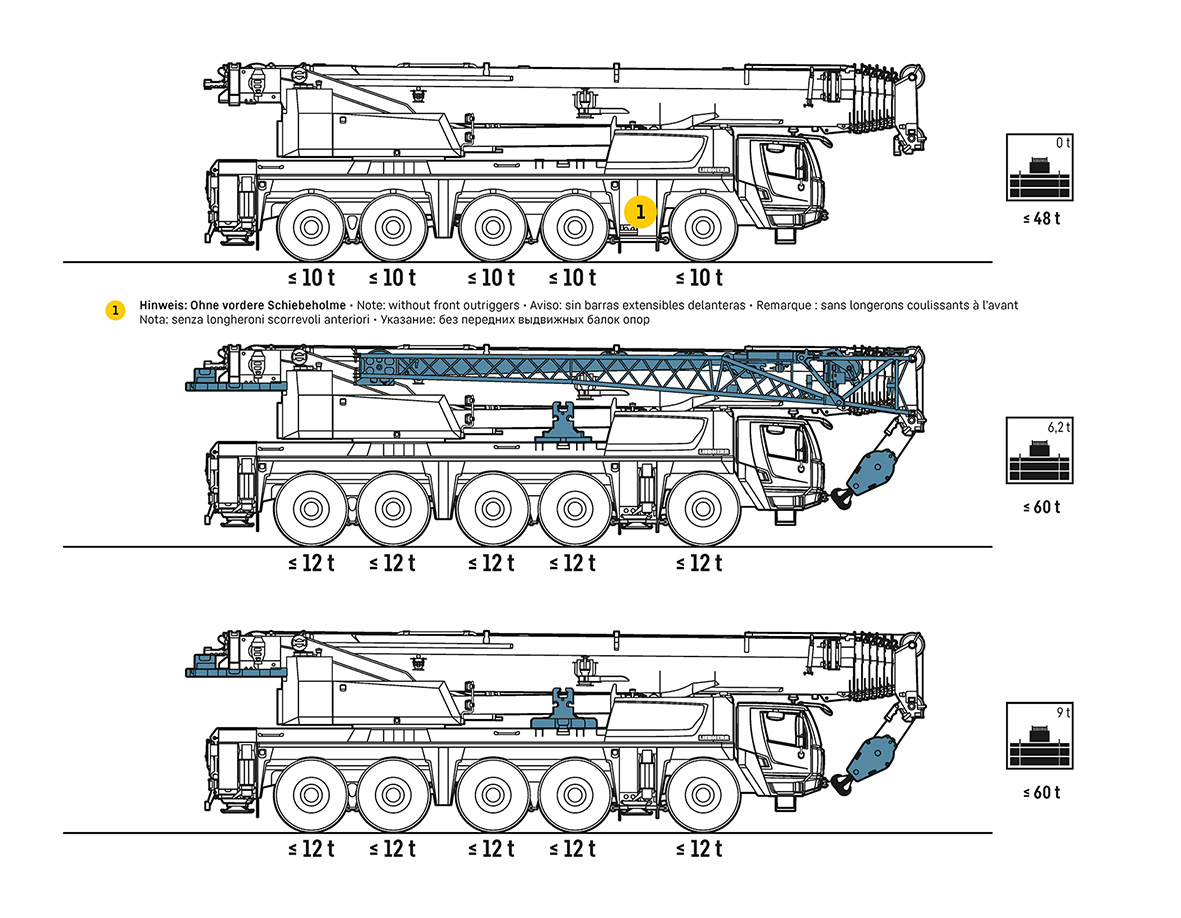

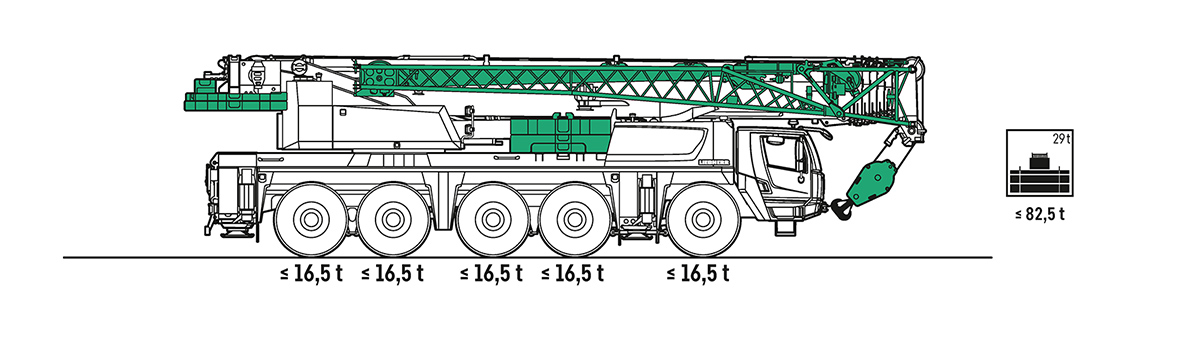

Driving conditions

On-road driving

Jobsite driving

Ballast systems

Counterweight

Technology

ECOmode

ECOmode minimises both fuel consumption and noise emissions when operating the crane superstructure. The crane operator sets the required working speed using the control lever. The crane control system calculates the perfect engine speed for the diesel engine.

ECOdrive

ECOdrive makes the mobile crane significantly more comfortable and quieter by reducing the engine speed. Faster gearshifting delivers greater dynamic and traction offroad. On the road, the torque from the Liebherr diesel engine is used efficiently to minimise fuel consumption.

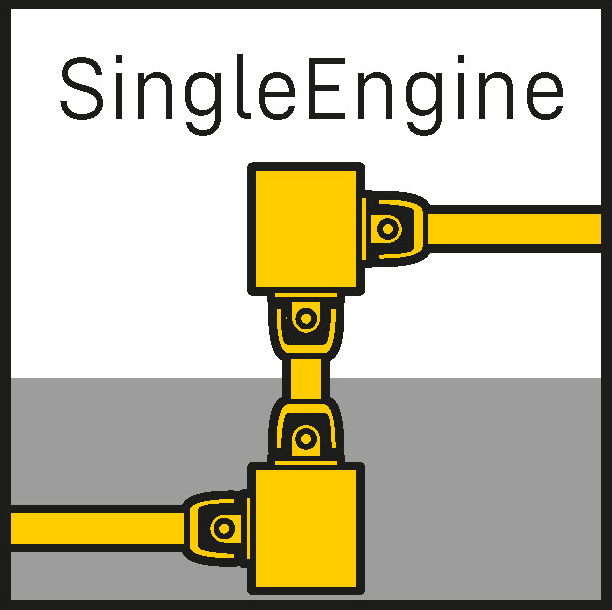

Single-engine concept

Take one engine out to increase lifting capacity. Or more accurately – the superstructure is powered by the undercarriage engine. Gear shafts are routed from the distributor gear in the substructure via two mitre gears to the pump distributor gear in the superstructure. That enables us to remove one engine – and we use this to increase the crane’s lifting capacity.

Hillstart-Aid

Hillstart-Aid makes starting on gradients easier. Move off safely and easily without rolling backwards.

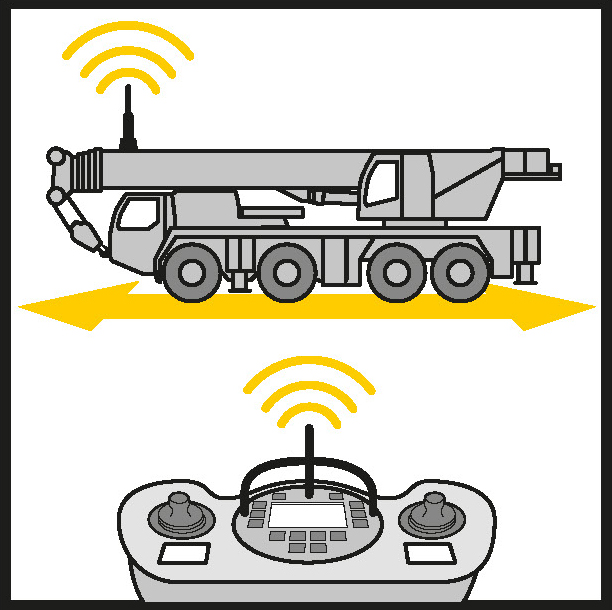

RemoteDrive

The RemoteDrive remote control enables the crane to be controlled from outside the driver’s cabin. This is not only possible during crane operations, but also whilst driving on the site. This delivers greater safety and comfort as the crane operator has a better view of problem areas as he can be right next to them. In other words, the operator can move himself to the areas with difficult access.

LICCON3

The third generation LICCON control system features the same time-tested operation as previous generations and adds a fast data bus, significantly more storage space and greater computing power. LICCON3 cranes are prepared for telematics and fleet management.

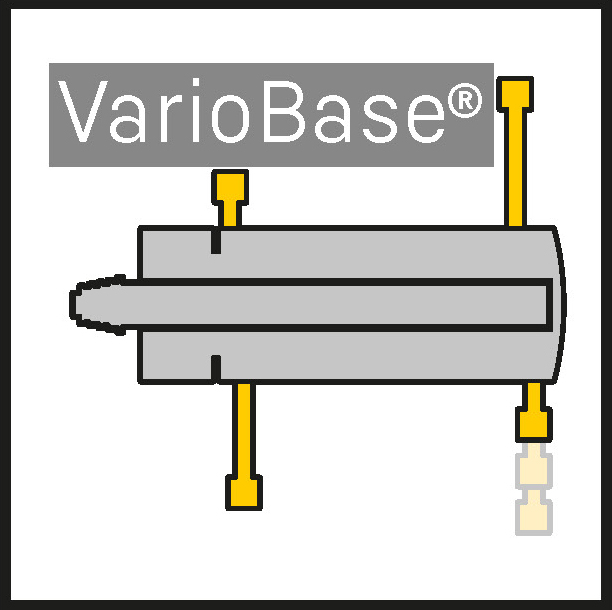

VarioBase®

VarioBase makes the crane’s support system variable. It enables each outrigger to be extended to a different length. This enhances safety – particularly in constricted spaces. And what's more, the crane’s lifting capacities are significantly increased, particularly over the outriggers and depending on the configuration.

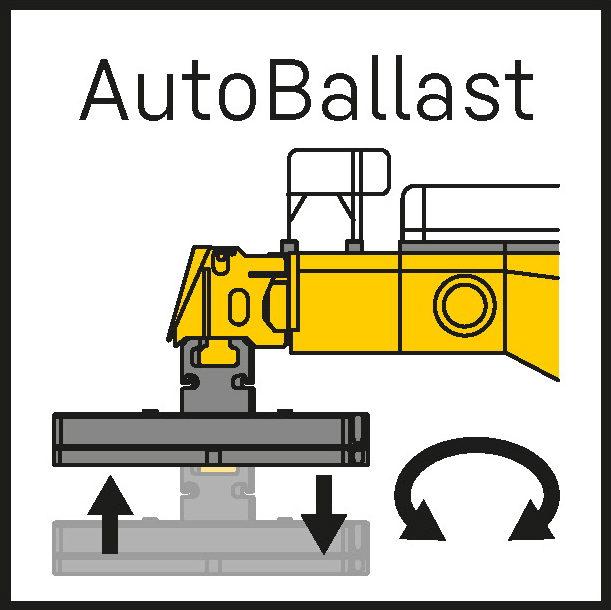

AutoBallast

The AutoBallast function completes the ballasting process automatically. All the steps are carried out after the button has been pressed just once.

WindSpeed load charts

Increased flexibility and safety by using lifting capacity tables with different maximum wind speeds.

HVO ready

Up to 90 % lower CO2 emissions in action.

Assistance-systems

Driver assistance systems for extra safety on the road. All new mobile crane models are equipped with driver assistance systems

that support the crane driver with additional „eyes“. They scan the environment and warn the crane driver to prevent accidents.