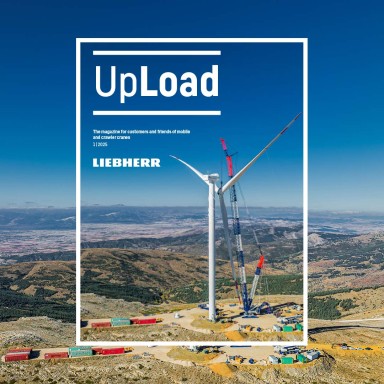

4 Minuten - Magazin 01 | 2025

Powerful transport marvel

It has become a telescopic crawler crane in a class of its own: our new LTR 1150.

Debut in the Netherlands – the new telescopic crawler crane

Located between the models with a lifting capacity of 100 and 220 tonnes, the powerful new crane can be transported completely with its crawler travel gear and a total weight of 60 tonnes, just like the LTR 1100. The first construction site for the LTR 1150 was near Lelystad in the Netherlands, an hour’s drive from Amsterdam.

Crane driver Henk Poot: “A major benefit is the fast relocation from one construction site to the next.”

Our business partner and customer Vema Crane, based in Breda in the Netherlands, received the first new telescopic crawler crane and sent it brand new to the IJsselmeer in December for the construction of a huge logistics centre. The LTR 1150 had to cope with walls, base plates and pillars made of reinforced concrete with unit weights of up to 14 tonnes. “A really practical crane for concrete construction,” explains Henk Poot in the cab of the new machine. “I’m driving it here with a 45-metre telescopic boom and fully ballasted.”

Long and powerful: Lattice jibs can be added Long and powerful: Lattice jibs can be added to the 52-metre telescopic boom. Hook heights of up to 83 metres are possible.to the 52-metre telescopic boom. Hook heights of up to 83 metres are possible.

Henk confidently copes with all requirements on his first day in his new machine. The crane does it all. The crawler carriers push through the muddy construction site with- out any problems. “I can get through everywhere,” says Henk, “and later, when the space becomes less and less or several stored elements take up too much space, I can adjust the crawler carriers to a narrower track.” Three different track widths from 3.5 to 5.8 metres are available to the crane driver – the narrowest version is also the measure for the transport width of the first telescopic crawler crane equipped with VarioBase®. Henk Poot, who claims he is more of a mechanic than a crane driver, gets on very well in his crane operator’s cab when manoeuvring and setting the concrete parts. “I’m just starting to work with the new crane today, so I still need some practice. But I am enjoying these first few hours with the LTR 1150.”

“Maximum lifting capacity machine with efficient transport.”

And another customer is also clearly pleased with the machine: Tom Vanpassel, Managing Director of the Belgian branch of the Willy Naessens construction group, has arrived with three colleagues especially for the first deployment of the LTR 1150. “We are considering adding a few LTR 1150 vehicles to our fleet and want to get an idea of the crane today.” For him, the dimensions of the telescopic crawler crane are crucial for efficient transport. “When we move a small lattice boom crawler crane from one construction site to another, it takes us four days. Two days for disassembly and assembly, one day for transport and another day for testing and acceptance of the assembled crane.”

Belgian invasion: Tom Vanpassel (right), Managing Director of Belgian construction company Willi Naessens, inspects the brand-new construction equipment with his colleagues.

A special regulation in the Benelux countries and necessary when a construction machine is reassembled from its individual parts. “This specification does not apply to the LTR 1150, which we can fully transport with crawler carriers. One day is sufficient for us to get the crane to the next site. Ballast on top, done. The LTR 1150 is the machine with the highest lifting capacity on the market that can be transported in its entirety. The telescopic crawler crane also requires significantly less space, as there is no need to mount a lattice boom on the ground.”

This article was published in the UpLoad magazine 01 | 2025.