The new crawler crane – now with innovative derrick system

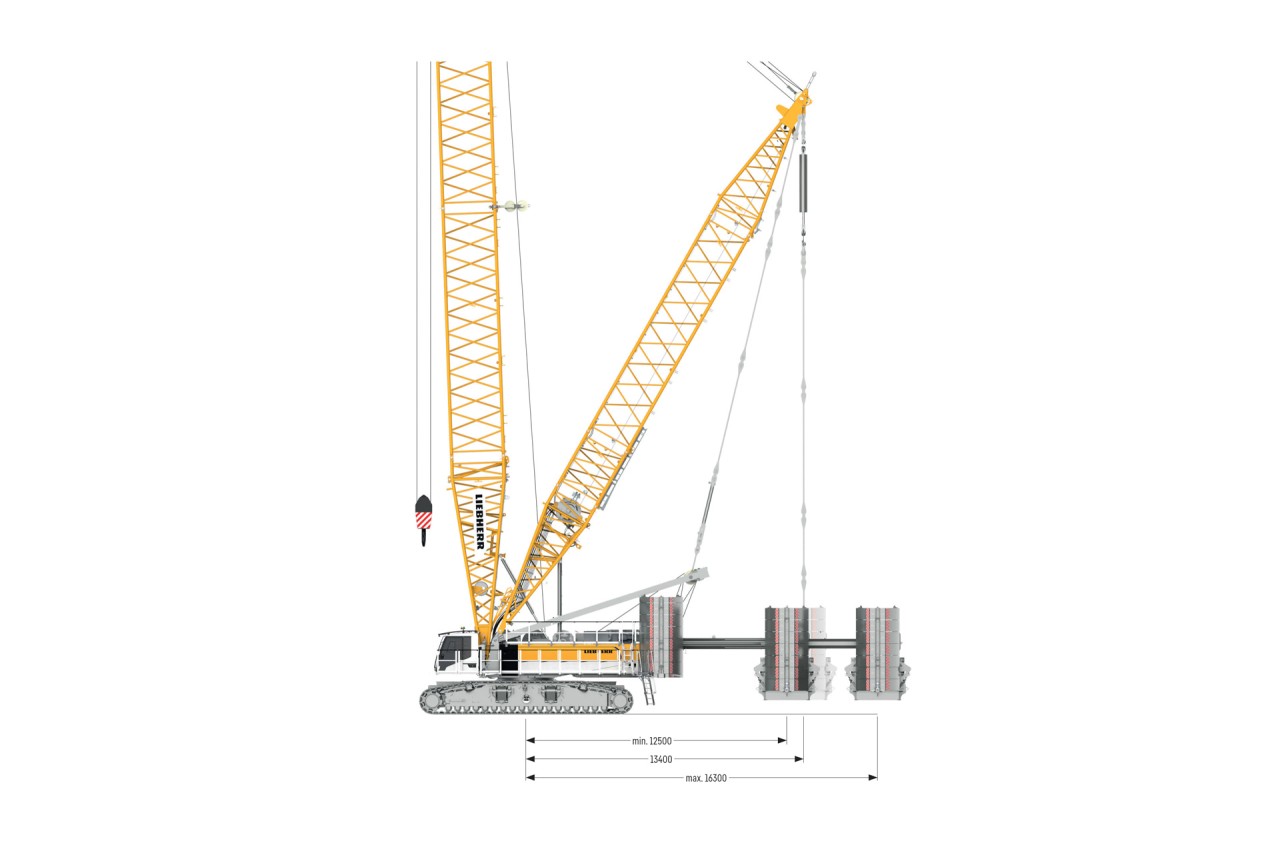

The new crawler crane enhances the proven performance of the LR 1400 SX with the flexibility of an innovative derrick system – for even higher lifting capacities and maximum efficiency on the jobsite.

Technical data

| Max. boom length | Max. pulley height | Data sheets | |

| without derrick system | 178 m | 178.6 m | Data sheet LR 1400.1 SX |

| with derrick system | 220 m | 217.2 m | Data sheet for 400 t crane |

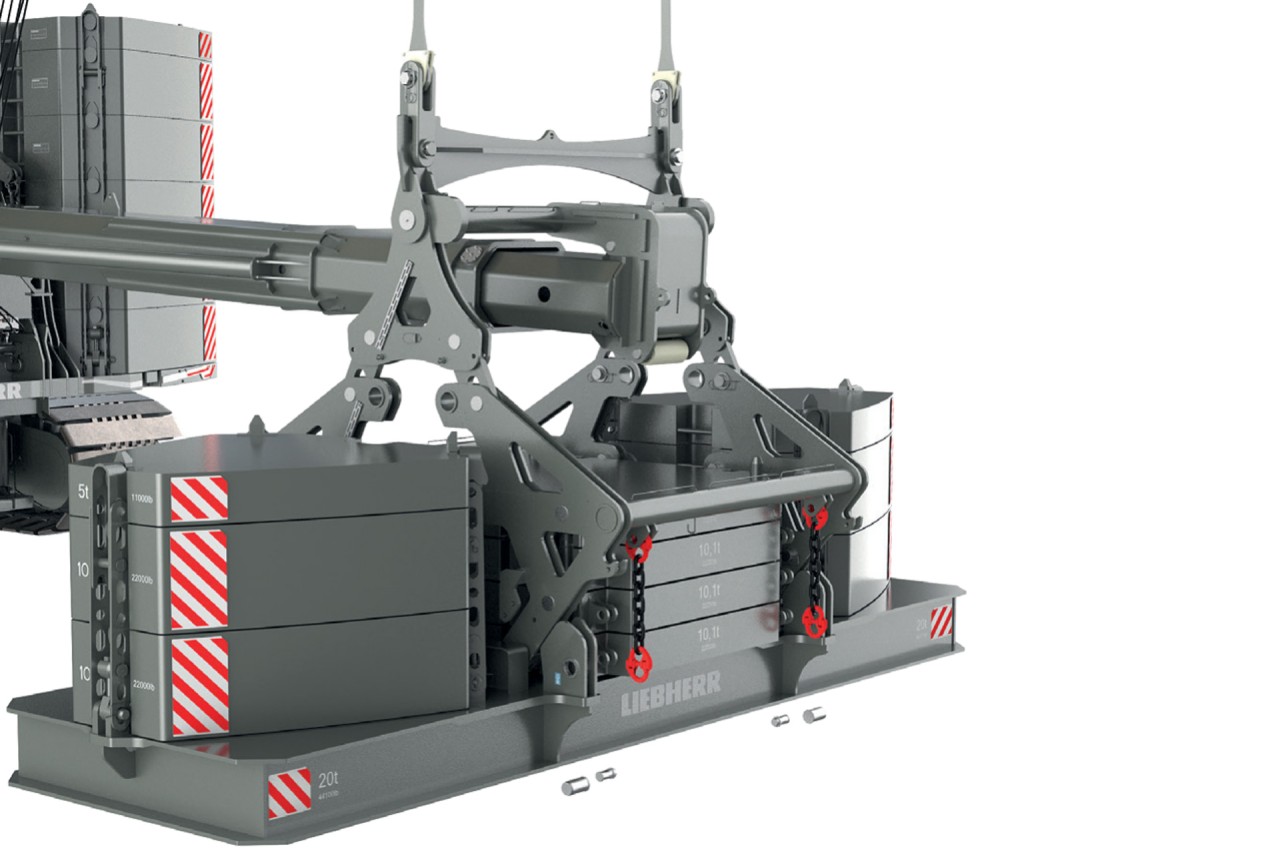

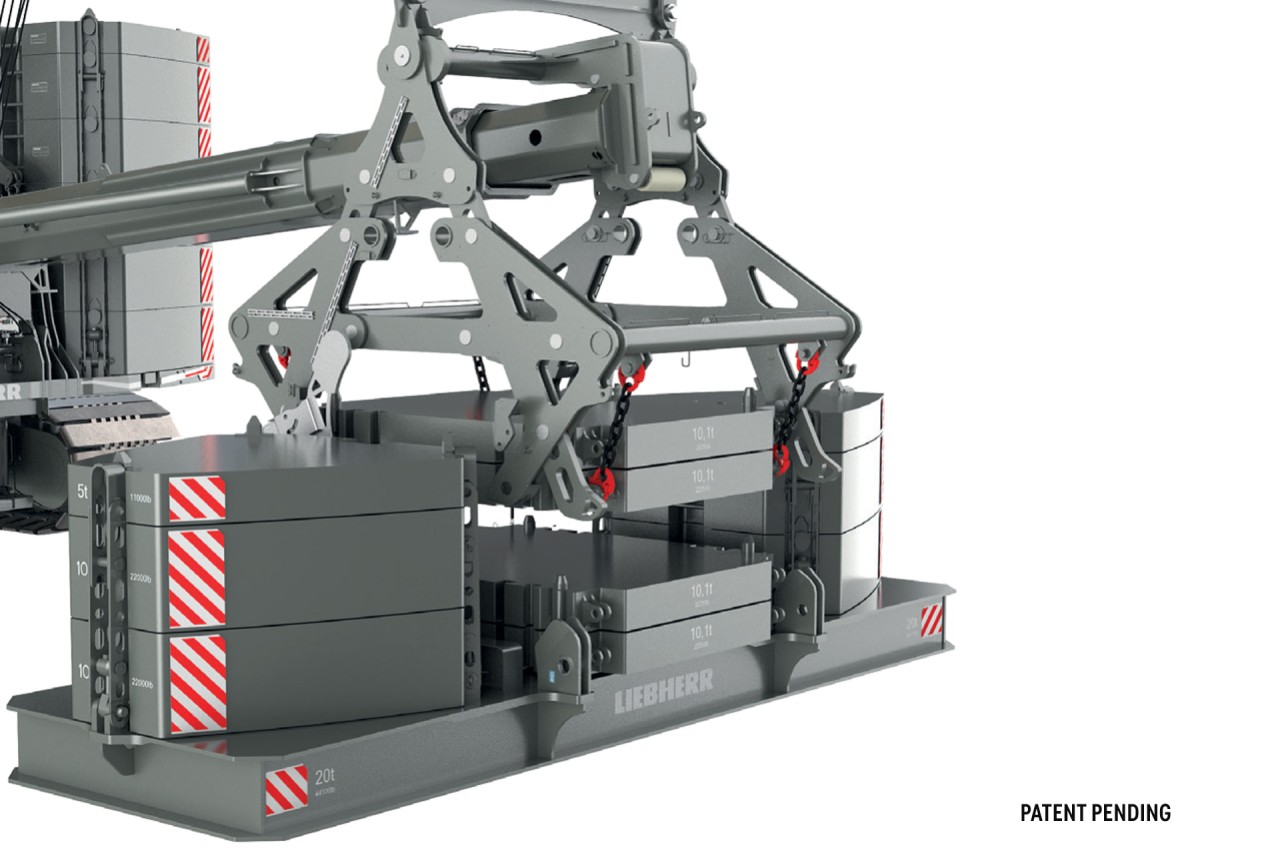

Application of the VarioTray system

Machine characteristics

Detailed crawler crane portfolio

Creating new ways

Liebherr crawler cranes are certified for lifting jobs on pontoons. The application as floating crane opens up a multitude of possibilities. Rivers can be used as an extended working area, especially in built-up areas where space is restricted.

Video

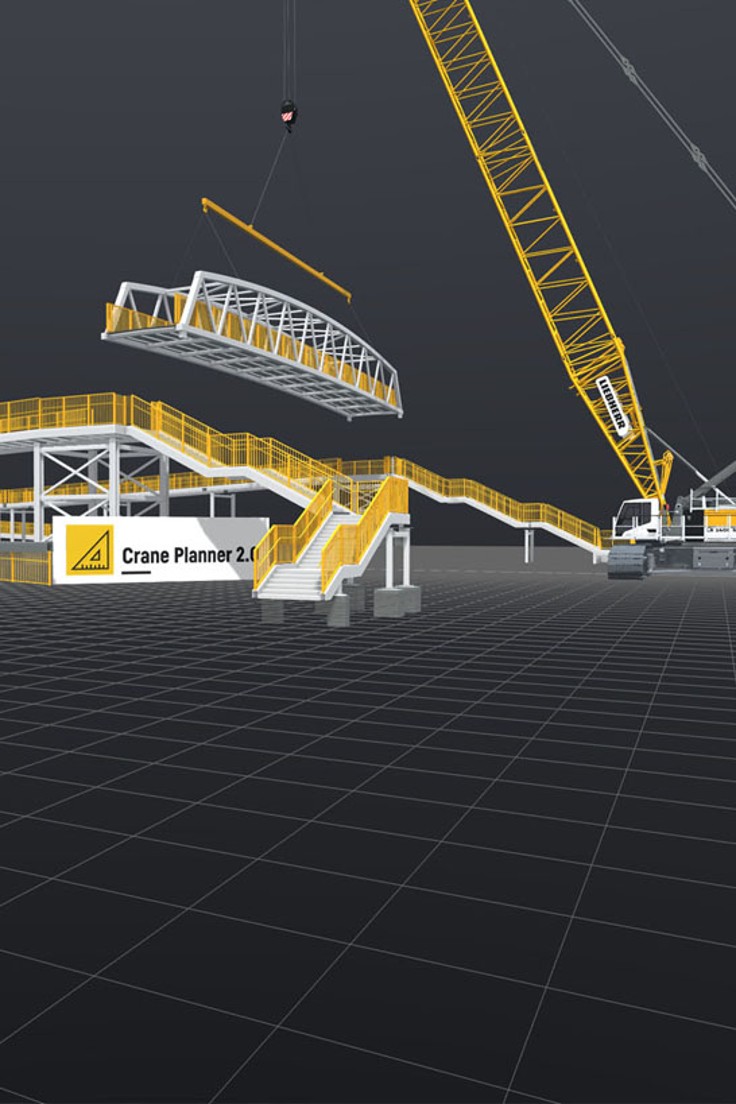

Digital solutions for lifting

Modern IoT solutions and services are revolutionising collaboration between people, machines and environment, making construction sites fit for the future. These include tools for planning construction site management, assistance systems for operating machines and remote maintenance solutions for service technicians.

Assistance systems

Operating a crane can be very demanding during lifts. The latest crawler cranes feature innovative assistance systems that enhance safety and simplify handling. These systems perform calculations in the background and keep the operator informed of all system states at all times.

Vertical line finder

The vertical line finder boosts safety and convenience by preventing load sway and collisions during lifting. It automatically aligns the load hook vertically above the centre of gravity, ensuring precise, straight lifting operation and reducing risks on site. This system simplifies the operator’s work, enhancing both efficiency and safety.

Boom up-and-down assistant

The boom up-and-down assistant increases safety by preventing the crane from tipping during boom and jib movements, even without a load. The assistance system warns of tipping risks, stops unsafe operations automatically and helps the operator to exit danger zones without activating the safety bypass switch.

Assistance system for travelling on a gradient

Gradient travel aid

Safely on the move on uneven terrain – the machine’s control system automatically calculates the centre of gravity and provides real-time inclination data and warnings.