T 264 Battery Electric

The future of zero emission haulage

Based on Liebherr’s proven T 264 mining truck, the T 264 Battery Electric is leading the charge for decarbonising the 240-tonne class. This 240-tonne capacity haulage solution not only plays an important role in reducing operational greenhouse gas emissions but is also compatible with a range of charging options, both static and dynamic, for optimal onsite flexibility. And on top of all this, the T 264 Battery Electric can be used autonomously, with Liebherr’s Autonomous Haulage Solution, to further enhance safety, productivity and efficiency.

Payload class - 240.00 t

240.00 t

Gross vehicle weight (GVW) - 416.00 t

416.00 t

T 264 Battery Electric highlights:

Zero emission

Flexibility

Faster speed on grade

Partnerships with companies and people like Liebherr – where ambition is backed by action – are critical ... This is an important next step in our 2030 Real Zero target – to eliminate emissions from our Australian iron ore operations by the end of the decade.

Making decarbonisation a reality!

Fortescue Zero is developing groundbreaking technology which push the boundaries of engineering, making industrial, enterprise decarbonisation a reality.

Liebherr and Fortescue Zero are working together to integrate the battery power systems developed in-house at Fortescue Zero, into Liebherr's mining trucks, to create zero emission haulage solutions for the mining industry.

Technical data

| Payload class | 240.00 t |

| Gross vehicle weight (GVW) | 416.00 t |

| Empty vehicle weight (EVW) | 176.00 t |

| Drive system | Liebherr Litronic Plus AC drive system with IGBT technology |

| Max speed | 55 km/h |

Downloads

Videos

Introducing our T 264 Battery Electric truck

Machine gallery

Automation and electrification: The future of mine haulage

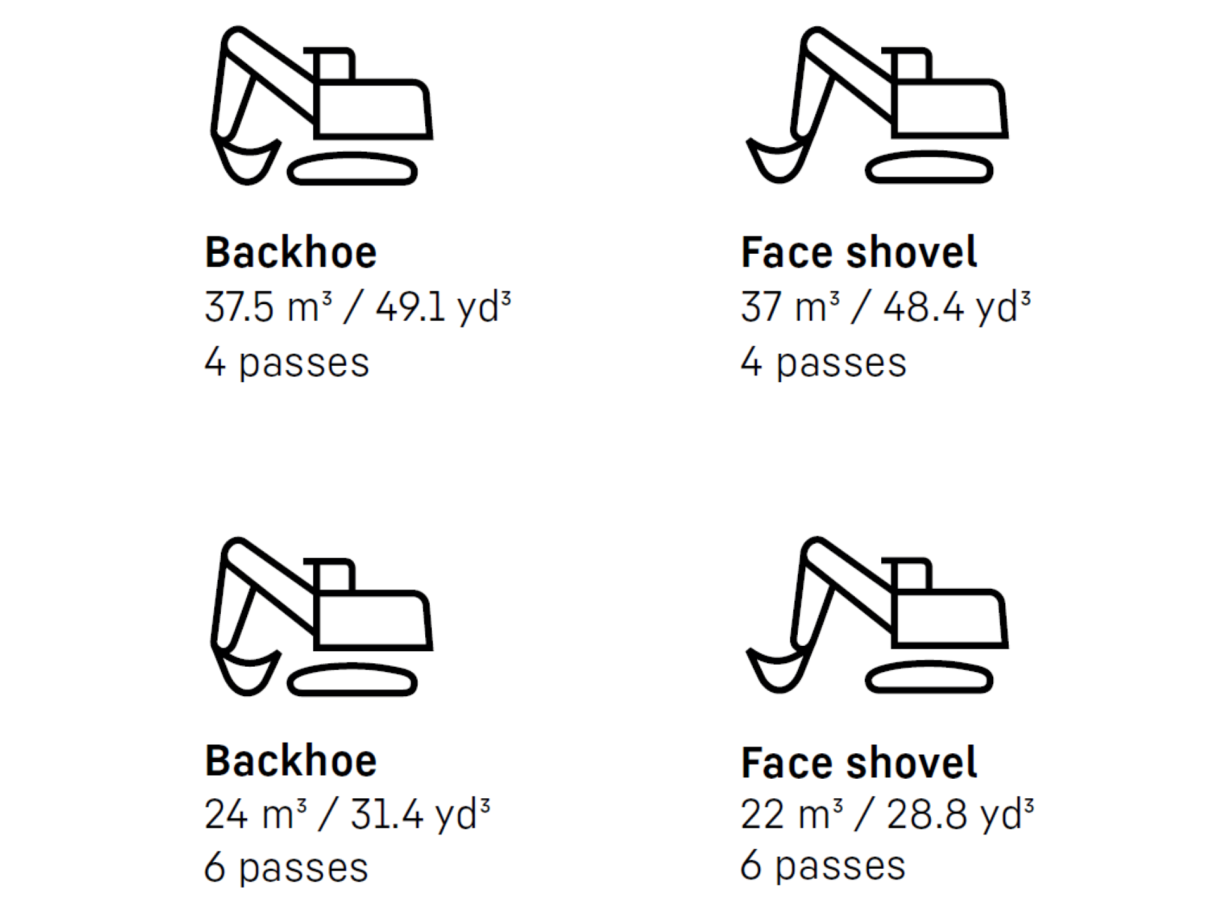

Truck excavator match*

*Site-specific factors like loose material density, bucket size, fill factors, truck body size and payload capacity will influence pass match. Contact your local Liebherr sales and service company or sales partner for analysis of your site.

The perfect Liebherr pairing

Discover the perfect pairing for the R 9400 and R 9600 excavators with our innovative truck match solution. Explore the seamless synergy between our advanced excavator technology and high-performance mining trucks, setting a new standard for excellence in the industry.