Even greater performance: the new fibre cranes

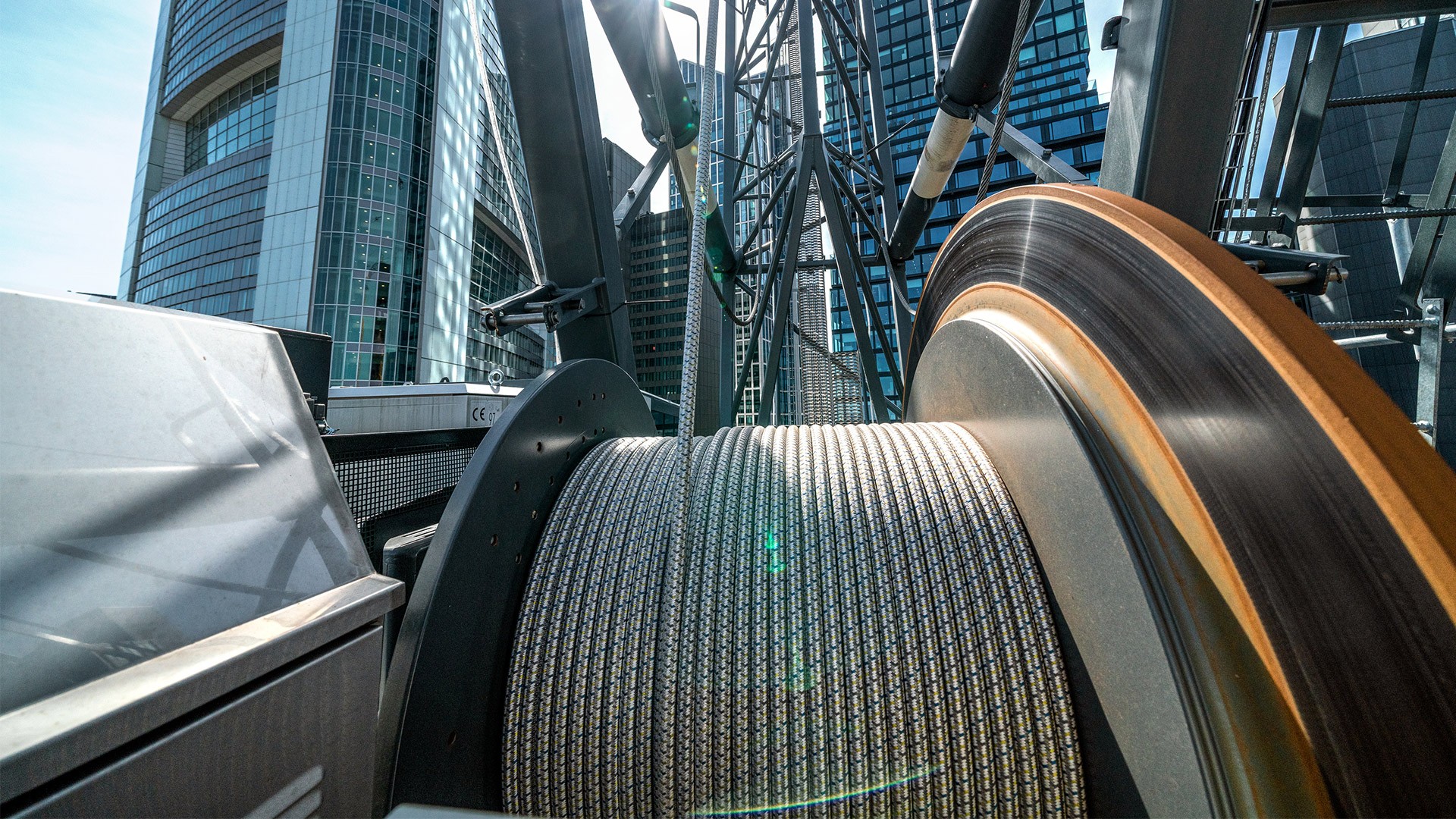

We are showing our large cranes with fibre technology for the first time at Bauma 2022. The advantages of using fibre rope become even more apparent with these machines, as the impact of the significantly lighter rope becomes more noticeable with each additional metre of hook height. Designed for lifts up to ten tonnes, the high-tensile fibre rope has a diameter of 25 millimetres (existing versions measure 20 and 22 millimetres) and is, for example, part of the 258 HC-L 10/18 Fibre luffing jib crane.

This increase in performance is particularly noticeable with the HC-L cranes, our specialists for high hook heights. By opting for fibre rope, which is the result of 10 years of development work by Liebherr and rope manufacturer Teufelberger, jib head load capacities can be increased by up to 38 percent compared to steel counterparts. Plus, fibre rope also has a longer service life than steel rope. This means less frequent rope changes, resulting in reduced associated costs and less downtime. Assembly and maintenance are also more straightforward.

In addition, operational safety is also noticeably increased. The different elements of the rope’s outer layer wear out at different rates. When the red layer underneath the sheath becomes visible, the crane operator knows it’s time to replace the rope. Opting for fibre rope is also a way of reducing the crane’s carbon footprint.

Other cranes with fibre technology on display at Bauma are the 1188 EC-H 40 Fibre high-top crane and the 520 EC-B 20 Fibre flat-top crane. Also new at Bauma is the 370 EC-B 16 Fibre (not on show at the Liebherr stand).

Standard - EN 14439

EN 14439

Max. hook height - 96.00 m

96.00 m

Max. lifting capacity - 20,000 kg

20,000 kg

Max. radius - 83.00 m

83.00 m

Lifting capacity at max. radius - 2,900 kg

2,900 kg

Standard - EN 14439

EN 14439

Max. hook height - 94.20 m

94.20 m

Max. lifting capacity - 40,000 kg

40,000 kg

Max. radius - 90.00 m

90.00 m

Lifting capacity at max. radius - 9,100 kg

9,100 kg

Standard - EN 14439

EN 14439

Max. hook height - 64.80 m

64.80 m

Max. lifting capacity - 18,000 kg

18,000 kg

Max. radius - 60.00 m

60.00 m

Lifting capacity at max. radius - 2,500 kg

2,500 kg