Proven design. New format.

Proven design. New format.

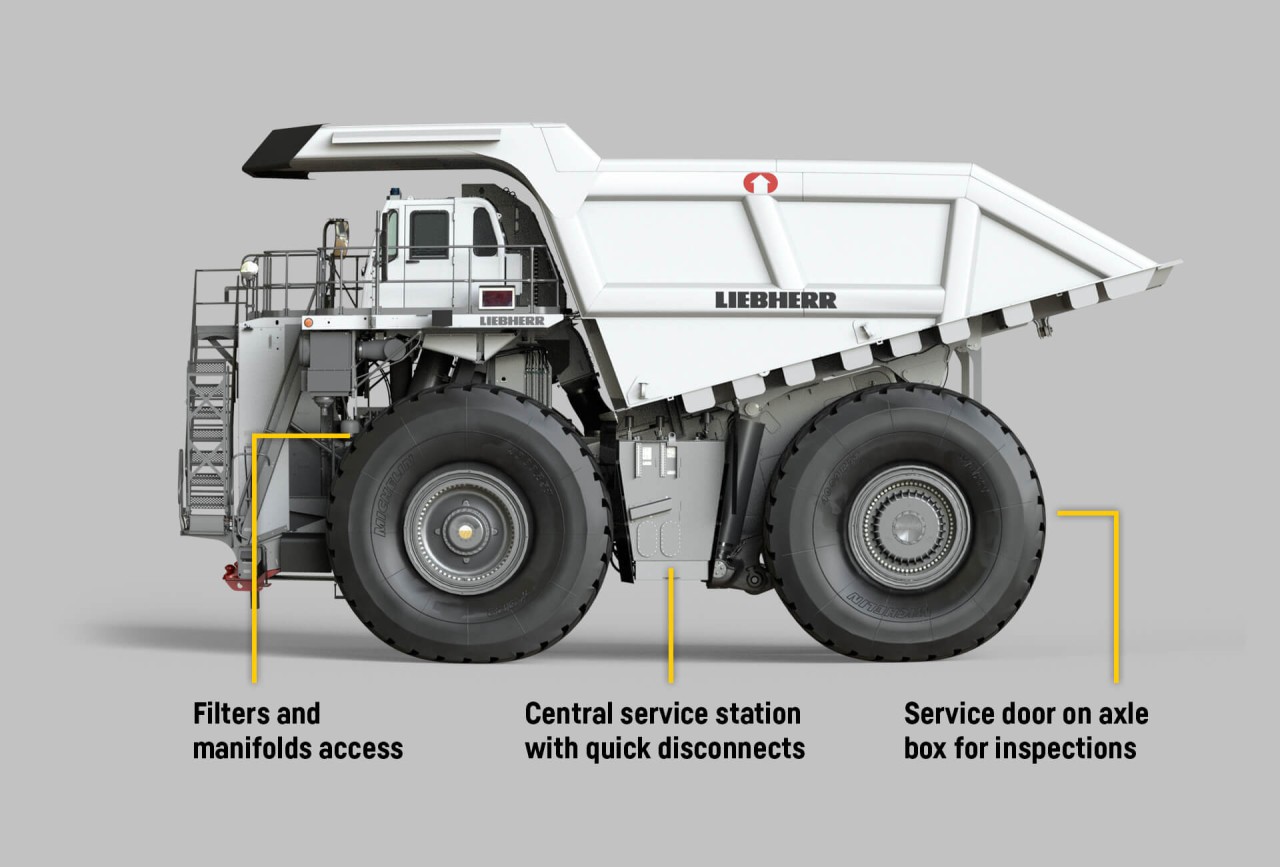

Liebherr T 274. The new 305 tonne payload truck.

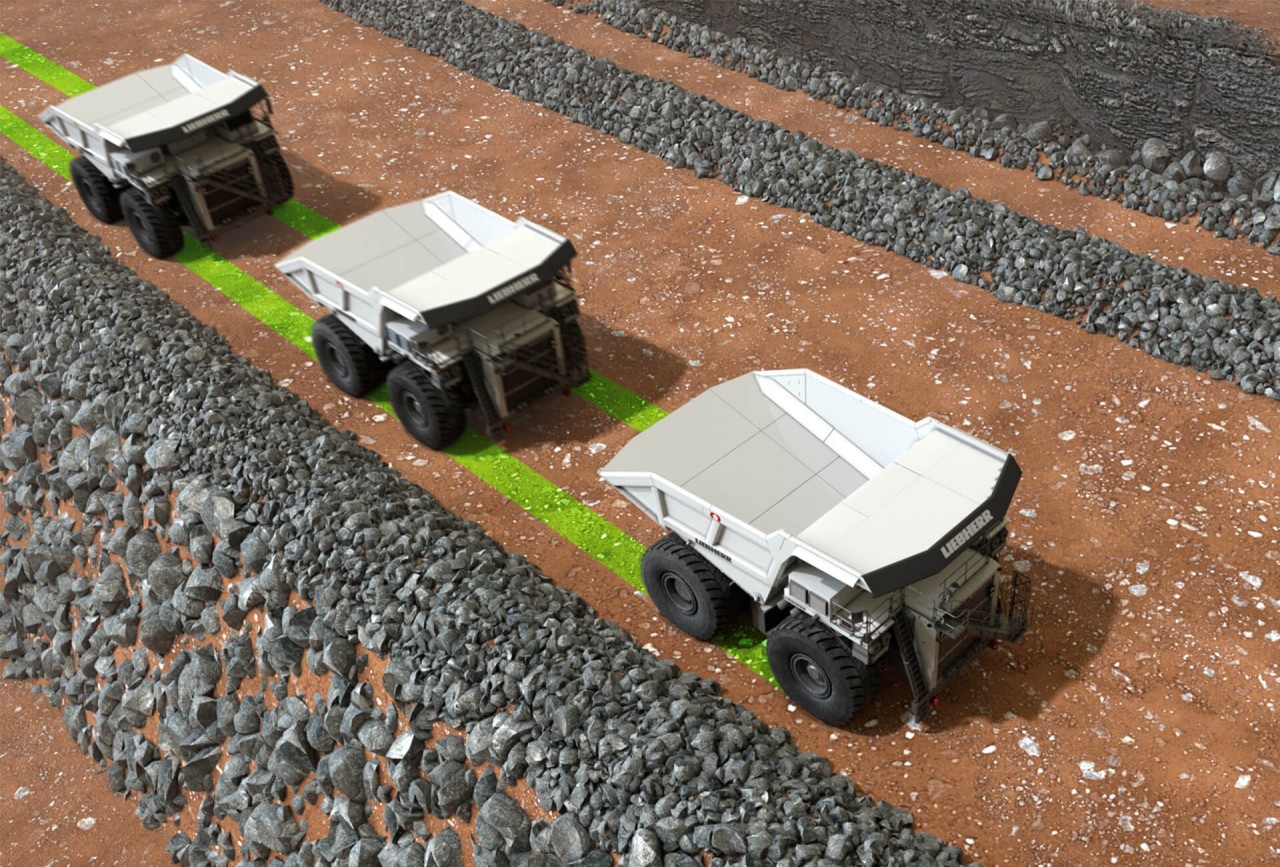

Liebherr is extending its product offerings with the T 274, a class-leading 305 t / 336 tons haul truck. This new truck bridges the gap between the highly successful T 284 (363 t / 400 tons) and the T 264 (240 t / 265 tons).

Operating the T 274 with other Liebherr Mining products provides the opportunity to achieve the greatest productivity, while minimising operating costs.

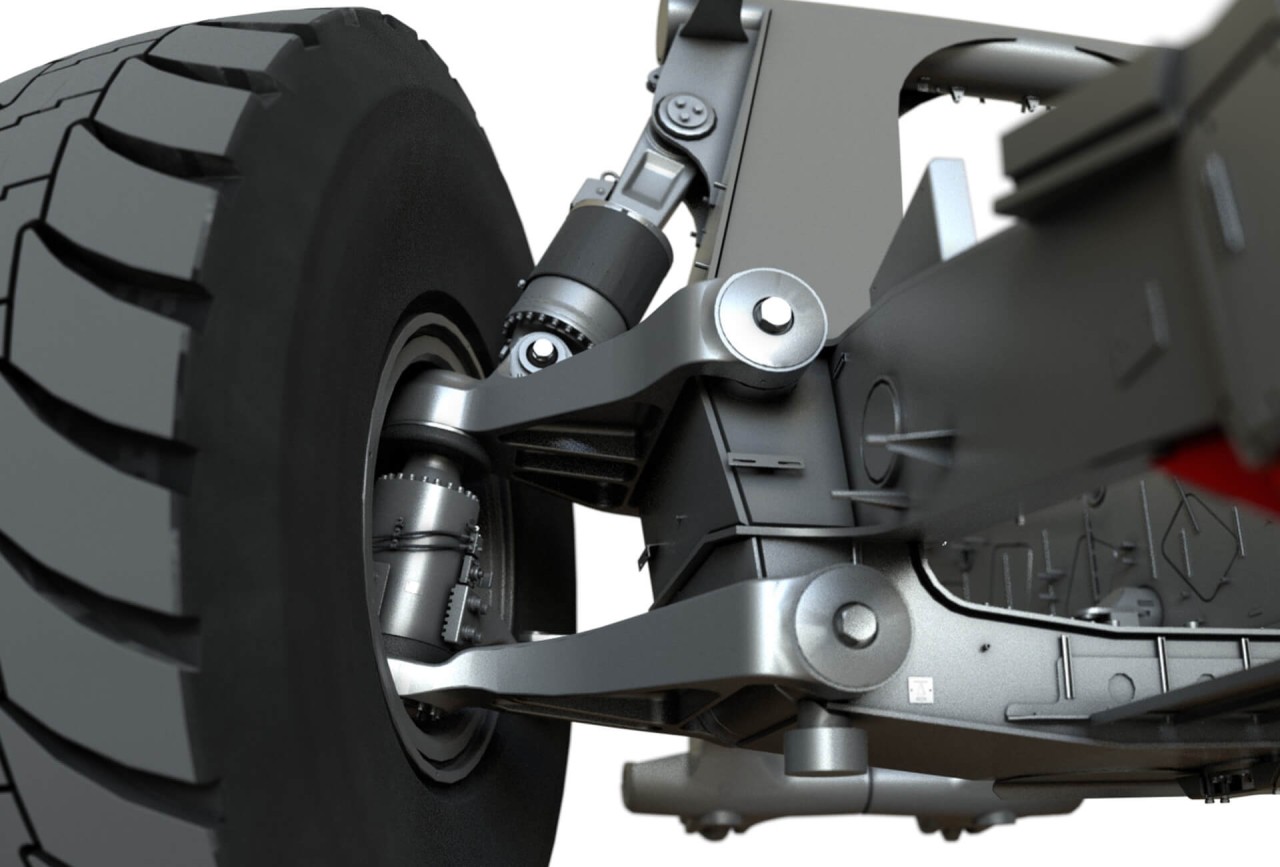

The T 274 follows the same base design as the T 284, benefitting from its decades of field experience. Operators and technicians can expect to experience first-class comfort and safety while driving and servicing this truck. A wide range of options are available, not only providing maximum productivity even in the harshest conditions, but also catering to the evolving requirements of customers and mine sites.

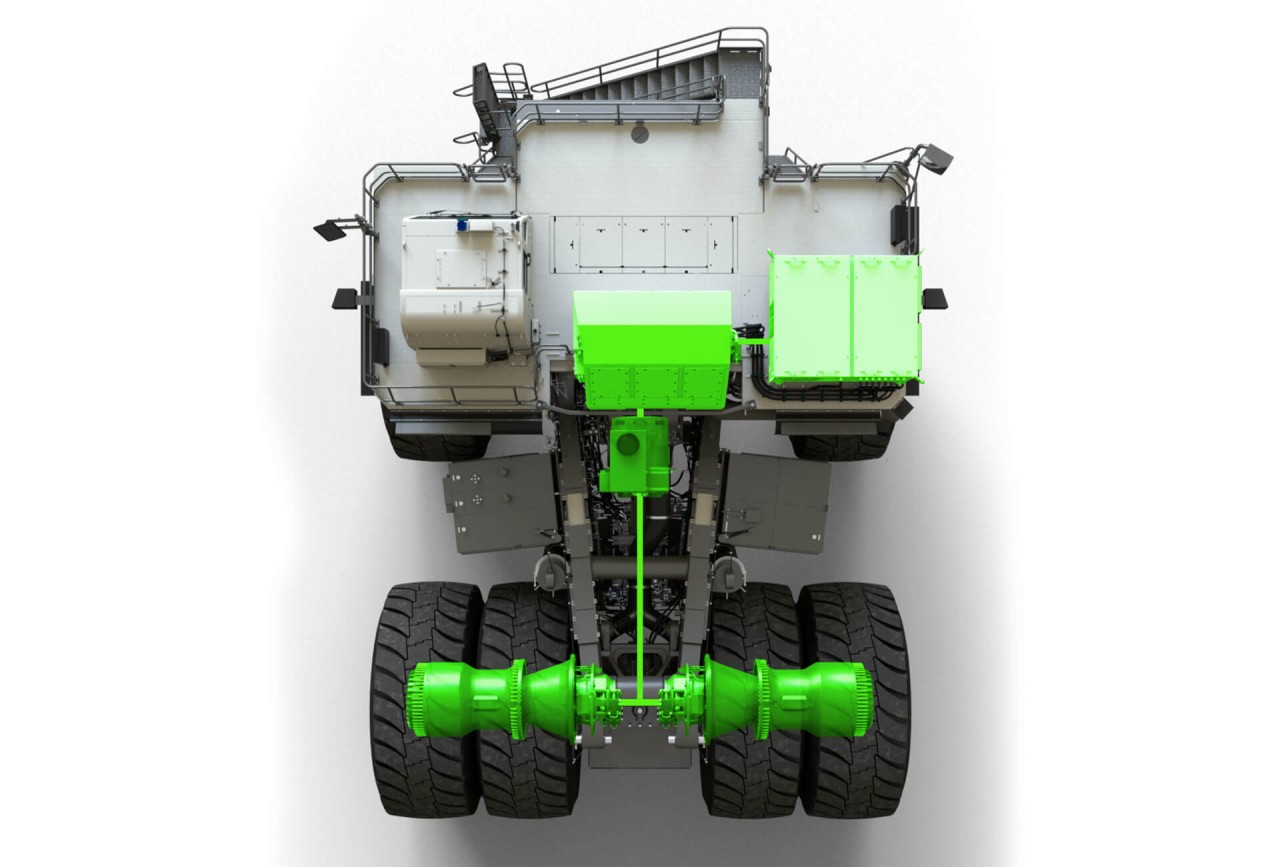

This new 305 tonne truck can be fitted with the Liebherr Trolley Assist System, a significant step towards zero emission mining.

Powerful, strong, and reliable

Designed and adapted from years of experience in mining truck development, the T 274 is a true 305 tonne machine that provides fast cycle times, higher production rates, low fuel consumption, and a low cost per tonne.

305 t

336 tons

528t

582 tons

2,720 kW

3,648 HP

5,351 l

1,414 gal

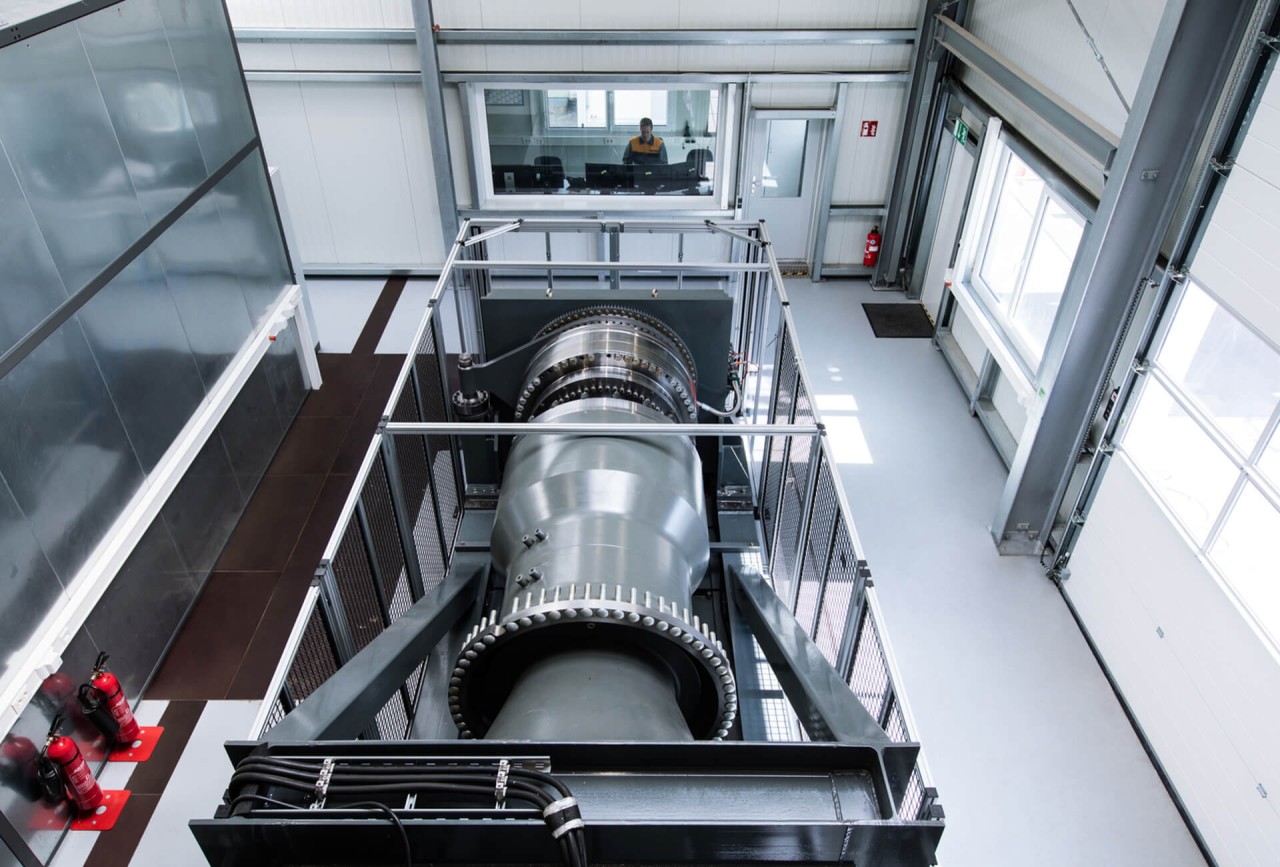

4,500 kW

6,035 HP

Perfect pass match with Liebherr excavators

Enhanced driving comfort