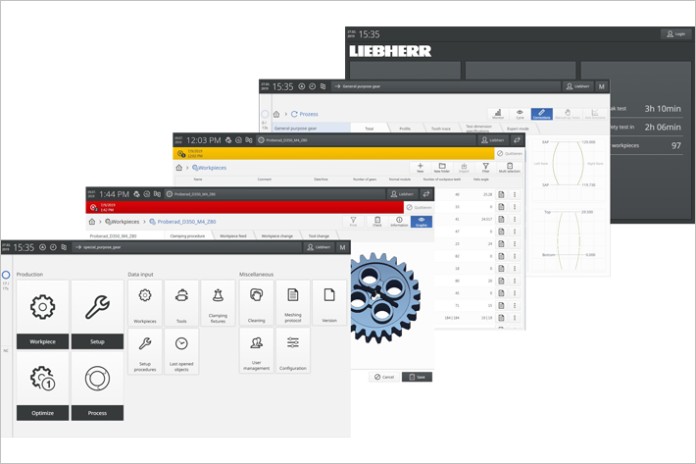

The new programming system from Liebherr:

25% faster set-up time

With the new LHGearTec software, the system constantly guides users when entering workpiece and tool data, as well as during workpiece correction and process monitoring. The user guidance was redefined in intensive cooperation with designers and users. Attention was also paid to the consistent integration of the control system in factory processes with open interfaces for both measurement processes (closed loop) and MES/MDE/PDA interfaces.

The connection with the new Siemens control generation and the new Liebherr control panel LHStation & LHMobile offer the following highlights:

- Quick access to the data records last modified

- Ergonomically optimized operating areas for tool and workpiece input

- Import and export of workpiece and tool geometries in Gear-Data-Exchange Format (GDE)

- Measured value transfer via GDE communication between Gear inspection machine and Gear cutting machine

- Optimized 3D visualization and process display

- Available for Gear hobbing, Gear grinding, Shaping and Gear skiving machines

- Possibility of integrating Siemens cycles for drilling, hobbing and turning operations

- "Digital-Twin" one-to-one programming version for creating workpiece programs during work preparation

- Support of tool changers

- Support of the new SINUMERIK ONE control platform