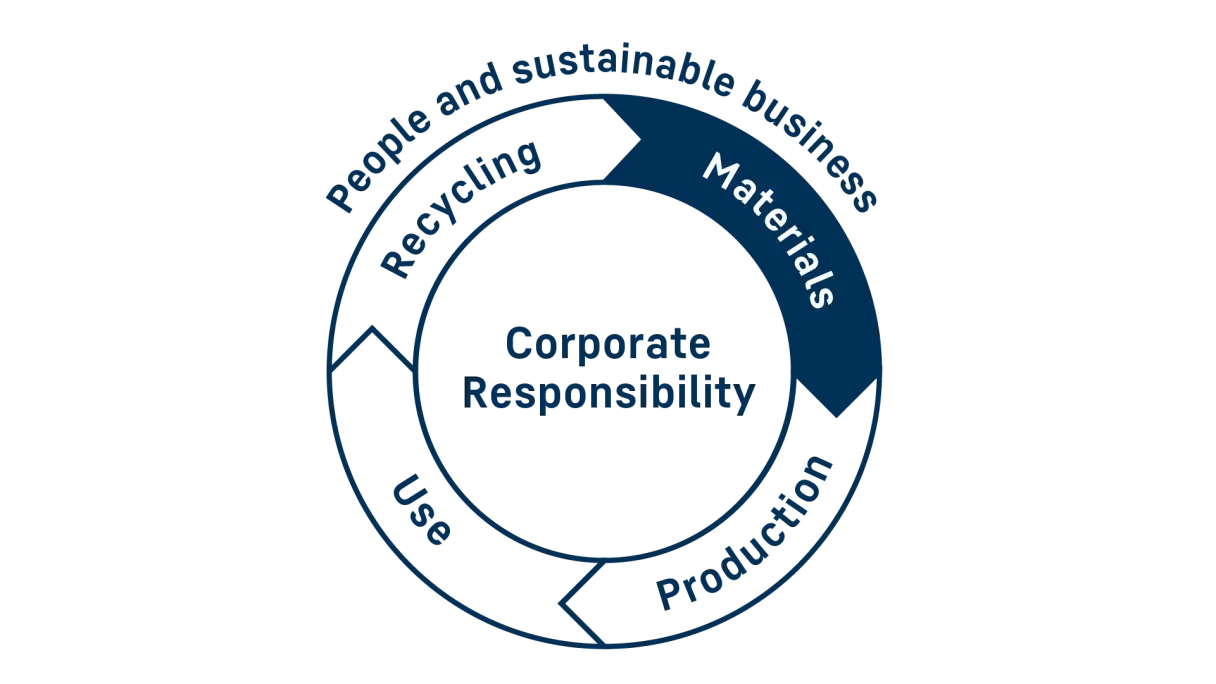

Materials

Materials

It begins with the materials we choose

Our appliances are renowned for their craftsmanship, quality, and efficiency — and it all begins with the materials we choose. Each component is selected to ensure durability and timeless aesthetics. From the robust steel exterior to advanced insulation, every element is crafted to guarantee an exceptionally long lifespan and a positive experience for our customers.

Main material groups

Using the freestanding freezer FNc 6625 as an example.

Made of robust sheet steel for structural integrity and timeless design.

Made from food-safe, easy-to-clean polystyrene.

Made using polyurethane for thermal efficiency and vacuum insulation panels (VIPs) for long-term energy savings.

Vacuum insulation panels (VIPs) with exceptional performance and long-term energy savings.

Made of PVC to maintain an airtight closure and enhance energy efficiency.

We have been relying on hydrocarbon-based refrigerants with low Global Warming Potential (GWP), which provide effective cooling with minimal environmental impact.

Other components used in our appliances

Our appliances combine advanced cooling technology and durable materials for efficiency, safety, and reliability. Additional components used in our appliances include:

Copper and aluminium ensure efficient cooling in refrigerant circuits, evaporators, and condensers, while durable compressors drive the cooling process. Reliable electronic components control temperature and lighting.

Tempered glass and plastics provide robust, food-safe storage that is easy to clean and long-lasting.

Added to plastics for enhanced safety, meeting strict fire standards without compromising food safety.

Regulations and requirements

The article stipulates that any supplier of an item must inform their customer if the item they supply contains a “substance of very high concern” in concentrations of more than 0.1% by mass. These substances of very high concern are also abbreviated to SVHC. The “SVHCs” are published in the “candidate list”, which is updated twice yearly and can always be accessed under: Candidate list

Our online search is designed to make it as easy as possible for you to find information regarding possible SVHCs contained in your appliance or spare part. We are obliged to inform you of these substances; their use is not prohibited.

Please keep in mind that the requirements for which SVHCs must be reported is amended by the European Chemicals Agency every six months. This means that any search is a snapshot.

If the appliance concerned is used as intended and disposed of properly, the substances it contains do not pose any risk to health or the environment. Your safety as well as that of your stored food is ensured. SVHCs may not be used if there is a risk that they might migrate into your food. The SVHCs are mainly either contained in inaccessible components (e.g. in the electronics) or firmly integrated in the substance of plastic materials. If, in individual cases, particular safety measures should become necessary, we will inform you of them on this site. You can search for appliances using the serial number or SKU (Stock Keeping Unit). For spare parts, please enter the nine-digit spare part number.

The Biocidal Products Regulation (EU) No 528/2012 governs the use and placing on the market of biocidal products and articles treated with such products. “Biocidal products” and “treated articles” are distinguished as follows.

Biocidal products contain at minimum a biocidal active ingredient and are intended to destroy harmful organisms such as bacteria or fungi. The regulation determines what products are permitted for certain applications. Products that are not permitted may not be used or placed on the market, Unless permission is applied for and granted. An example of a biocidal product is a protective wood glaze.

Treated articles are mixtures or products that have been treated with biocidal products or to which biocidal products have been intentionally added with the aim of preserving the articles themselves. They may only be placed on the market in the EU if they have been treated with biocidal products permitted in the EU. An example of a “treated article” is a fence panel treated with a protective wood glaze.

They are subject to a labelling requirement when:

- a reference is made to the product properties resulting from the biocidal treatment, and/or

- the approval for the biocidal active ingredient expressly requires this.

Currently, Liebherr-Hausgeräte GmbH is under no obligation to declare the use of any biocides.

Packaging

Protecting our appliances during transport is vital to maintaining quality and safety. Our packaging passes rigorous tests and is designed to minimise environmental impact. We use recyclable materials like expanded polystyrene (EPS), cardboard, and plastics.

Cardboard, our primary packaging, is recyclable, bio-based, and decomposes naturally if not disposed of properly. Strapping tape contains 30 % recycled content, while shrink film at the production site Ochsenhausen includes 52 % recycled material, with plans to expand this to all appliances.

Additionally, paper-based bags for manuals, documentation, and some smaller parts are provided for selected appliances.

Evolution meets revolution

Improving the present – Innovating for the future. We are continuously exploring new materials and better alternatives — materials that are more sustainable, more efficient, and designed for a circular economy. This pursuit is part of our ongoing effort to create appliances that not only meet today’s standards but also align with the Sustainable Development Goals of the United Nations, shaping a more responsible future.

Additionally, we are pushing forward with ground-breaking innovations. BluRoX, our revolutionary insulation technology, is redefining sustainability in refrigeration and freezing while adopting principles of circular design.

Every choice matters: The FNa 6635 with eco-responsible materials

The freestanding freezer FNa 6635 features 100 % recycled steel in its doors and sidewalls, resulting in 80 % less CO2 emissions during production compared to conventional steel. We have replaced traditional polyvinyl chloride (PVC) with thermoplastic elastomer (TPE) for the door seal, ensuring durability and better recyclability. Both the insulation foam and inner lining contain recycled and bio-based materials introduced through mass balance, providing the same exceptional performance with less environmental impact. Also, we have further reduced the ecological footprint of our packaging, without compromising on transportation safety.

Main eco-responsible material groups

Using our FNa 6635 as an example.

100 % recycled green steel in doors and side panels, cutting CO₂ emissions by 80 %.

Made from TPE, ensuring functionality, durability, and improved recyclability.

Highest possible percentage of raw materials from recycled or bio-based sources in the Mass-Balance approach, ensuring maximum performance with reduced ecological impact.

Contains the highest possible proportion of recyclates from post-consumer waste in the Mass-Balance approach, offering exceptional functionality with a reduced ecological footprint.

The future of packaging

We are committed to reducing our carbon footprint by adopting environmentally conscious packaging solutions. Each product’s unique size and transport requirements demand robust packaging that meets strict transport and stacking tests while aligning with our sustainability efforts.

Optimising packaging volume and weight helps reduce material use and environmental impact. We prioritise materials with high recycled content and ensure they are easy to integrate into existing recycling systems. For example, we have replaced plastic bags for accessories with paper alternatives and are switching to more sustainable options for strapping tape and shrink wrap.

With excellent collection rates and a fully recyclable, bio-based composition, cardboard reduces the need for virgin fibres and naturally decomposes if improperly disposed of.

Used for cushioning, rEPS is moisture-resistant, lightweight, and fully recyclable, made 95 % from recycled material to support a circular economy.

Our polypropylene tape contains over 30 % recycled material, ensuring durability while supporting sustainability goals. Also, we aim to replace EPS components with paper-based materials by 2028 and eliminate plastic use wherever possible.

BluRoX – rethinking the way we make things

We continuously rethink how we build our appliances, focusing on smarter material use and innovative technologies. Our patented BluRoX technology is one such breakthrough combining volcanic rock and vacuum insulation for superior energy efficiency. It reduces energy consumption and supports circularity by enabling easy material reuse and repairs.

Corporate Responsibility documentation 2024

For more comprehensive insights, data and in-depth details, see our full Corporate Responsibility documentation.

Continue reading

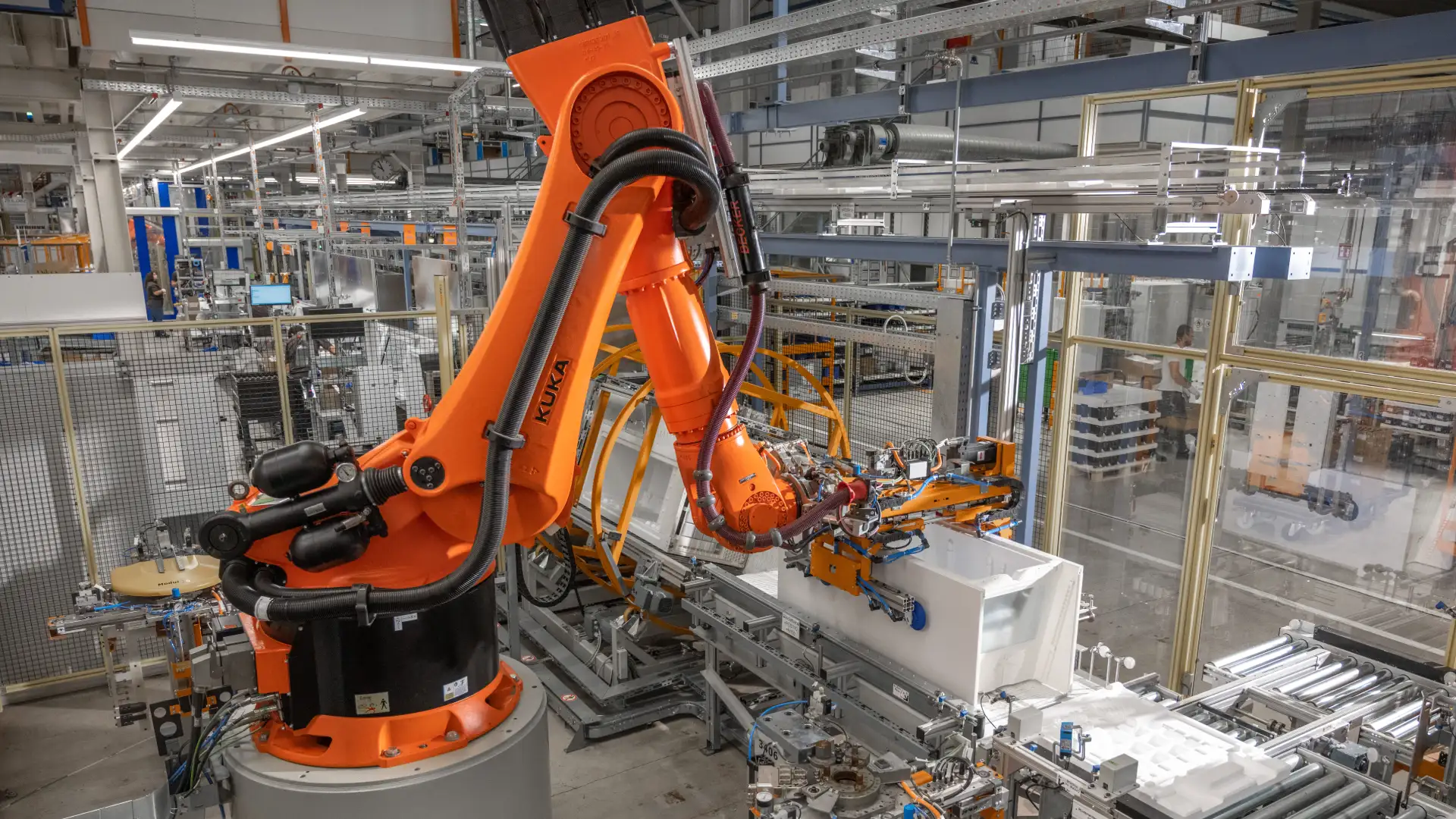

Production

We prioritise environmentally conscious production with the help of a wide range of measures.

People and Sustainable Business

People are at the heart of everything we do. Together, we are shaping a future built on innovation, integrity, and care for our planet.

Recycling

We are committed to designing products with end-of-life recyclability in mind. Our goal is to close the loop, contributing to a circular economy and a more sustainable future.