Initial step in expanding the machine platform for large gear machining

Gear cutting and grinding from a single source

Initial step in expanding the machine platform for large gear machining

Gear cutting and grinding from a single source

Initial step in expanding the machine platform for large gear machining

Gear cutting and grinding from a single source

Initial step in expanding the machine platform for large gear machining

Gear cutting and grinding from a single source

Liebherr-Verzahntechnik GmbH is continuing the systematic development of its platform strategy with the redesign of its machine platform for workpieces up to two metres in diameter. The new series encompasses all relevant gear technologies and is aimed at manufacturers of large gears, particularly in the mechanical engineering, marine propulsion, construction machinery and wind power industries. The lineup begins with hobbing and profile grinding machines designed for this size range – making it possible, for the first time, to perform precision hard machining on large workpieces.

By expanding the platform, Liebherr now offers the entire machining spectrum in this size range and is responding to growing demand for soft and hard-fine machining from a single source. “Our concept is designed specifically for this segment as a comprehensive solution,” explains Thomas Breith, Head of Product Management for Gear Technology. The new LGP 2000 enables profile grinding of workpieces up to 2,000 millimetres in diameter. In future, customers will receive a machine package that includes hobbing and grinding – a combination that is often used in the machining of large components.

Modular system

The redesign was focused on modularity, flexibility and reduced component diversity – with the aim of optimising delivery times and spare parts availability. All machines are built on a thermally symmetrical machine bed that is precisely temperature-regulated via circulating coolant. “This makes gear cutting and grinding even more thermally stable than with the previous machines,” explains Thomas Breith. The machines feature a high-precision, hydrostatically mounted table with wear-free direct drive. Depending on the machine type, flat or roller linear guides are used, which enable high damping during gear cutting and maximum precision during grinding and gear testing on the machine. Two main stand variants with 1,500 and 2,000 millimetres of stroke enable efficient machining of even particularly long shafts with multiple gear teeth. The platform’s machines are designed to accommodate automation solutions like pallet changers and ringloaders.

New gear cutting features: integrable chamfering device, optimised chip removal

A new feature is that the gear cutting machines offer an optional chamfering device with a conventional end mill (FlexChamfer) that can be used directly on the cutter head. This allows for cost-effective machining even with small batch sizes. When milling internal gear teeth, an integrated chip removal system eliminates the need for a separate, costly channel in the factory floor. The gear cutting machines are suitable for both dry and wet machining.

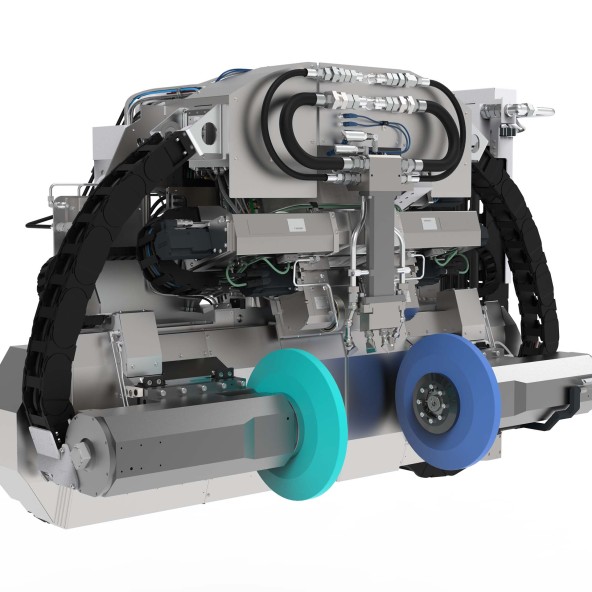

The new high-performance grinding head

Profile grinding: new LGP series for large gear teeth

Various grinding head configurations are available on the LGP for profile grinding of large gears (see figure above). A unique feature is the sequential use of two grinding wheels without a tool change. This allows different tool specifications to be used, which either shorten the grinding time or enable higher surface qualities to be achieved in production. LGP allows both high speed grinding and creep feed grinding. Single- or double-sided topological profile grinding and internal grinding using an optional, swivelling internal grinding arm are possible thanks to the modern LHGearTec. In addition to a conventional double dresser, the LGP can also be equipped with a double dresser for simultaneous dressing of both grinding wheel flanks. This allows dressing times to be almost halved and the productivity of the profile grinding machine to be significantly increased once again.

New platform: modular, economical, precise

The newly designed large machine platform offers consistent synergies across all machining processes, thanks in part to a uniform control interface. Shorter processing times for profile grinding reduce machine costs and thus reduce unit costs for the customer. The modular design also improves the availability of spare parts, ensuring high machine availability. The new hobbing and profile grinding machines will be unveiled at EMO in Hanover (Germany) in September 2025.