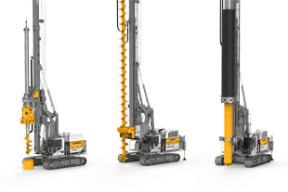

LB 30

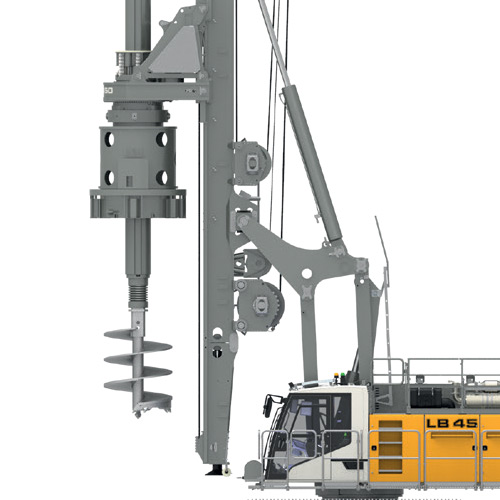

Drilling rig (LB series)

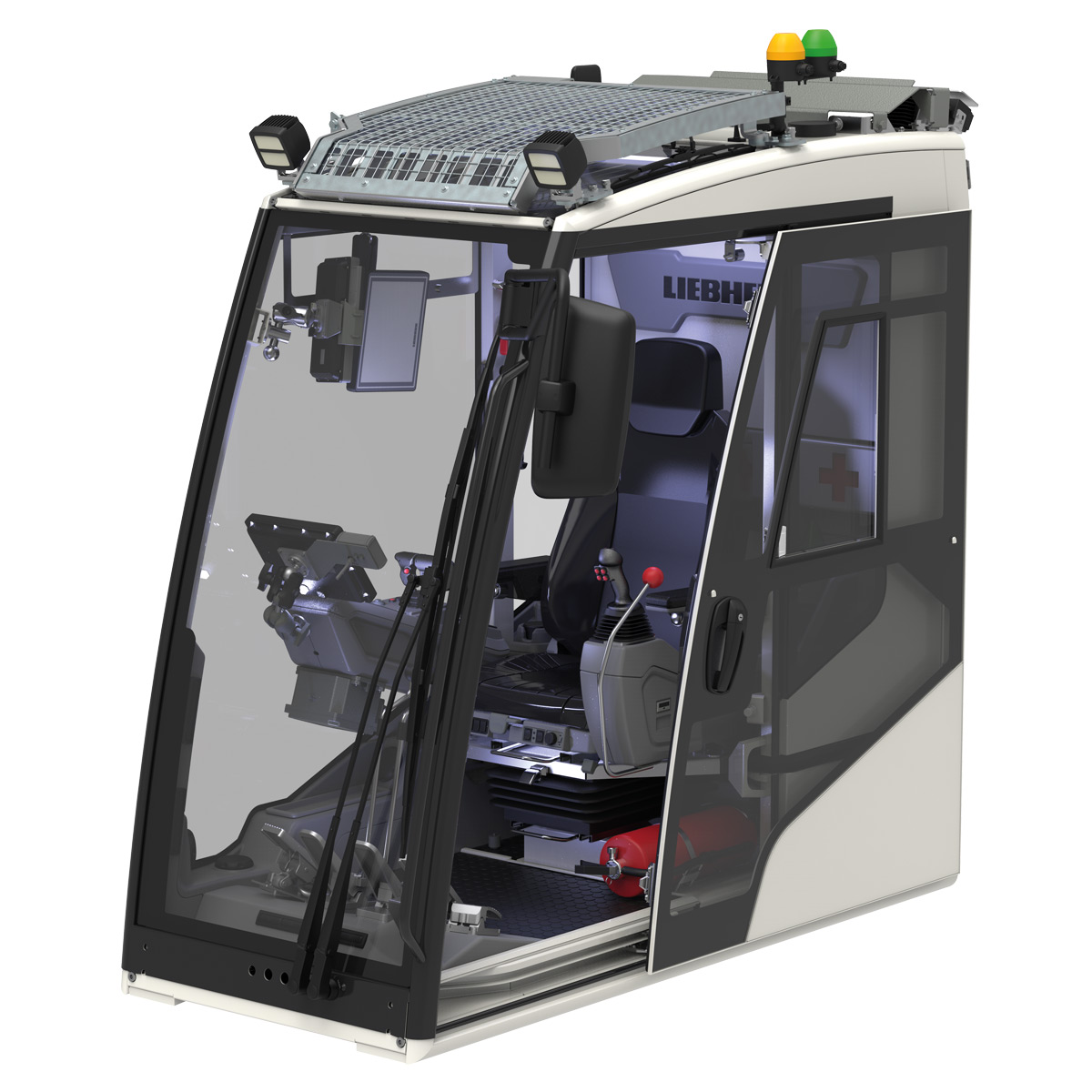

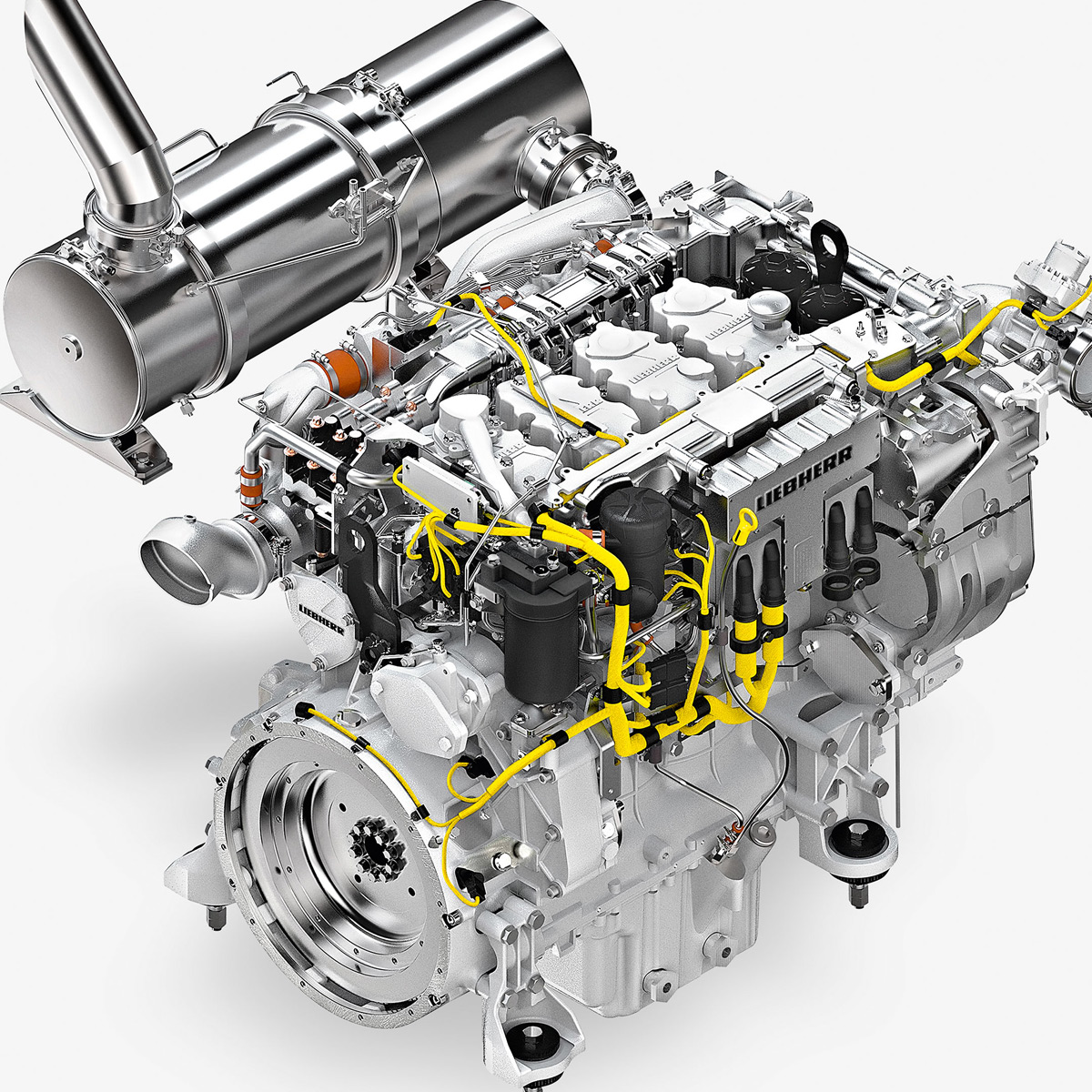

The LB 30 is the successor of the proven rotary drilling rig LB 24-270. Its torque is 297 kNm – a 10 % increase in comparison to its predecessor. Drilling with Kelly equipment, double rotary head and continuous flight auger are common methods. The machine can be transported with lowered leader system which enables a fast set-up time at the jobsite. The robust undercarriage provides an excellent stability. The leader can handle high torques and is also designed for high tractive forces of the rope crowed system. This allows for precise and fast drilling cycles.

Operating weight - 73.6 - 84.6 t

73.6 - 84.6 t

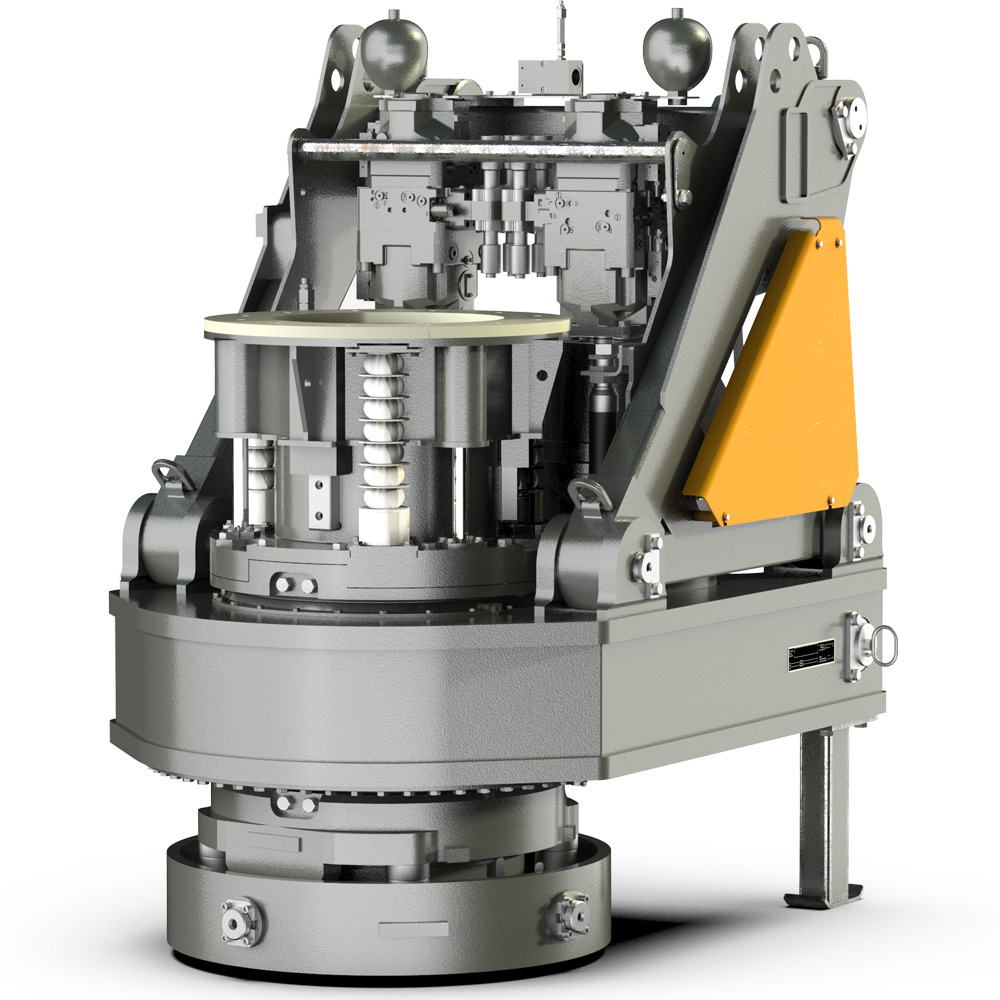

Max. torque - 297 kNm

297 kNm

Kelly drilling, max. drilling depth - 70.8 m

70.8 m

Kelly drilling, max. drilling diameter - 3,400 mm

3,400 mm