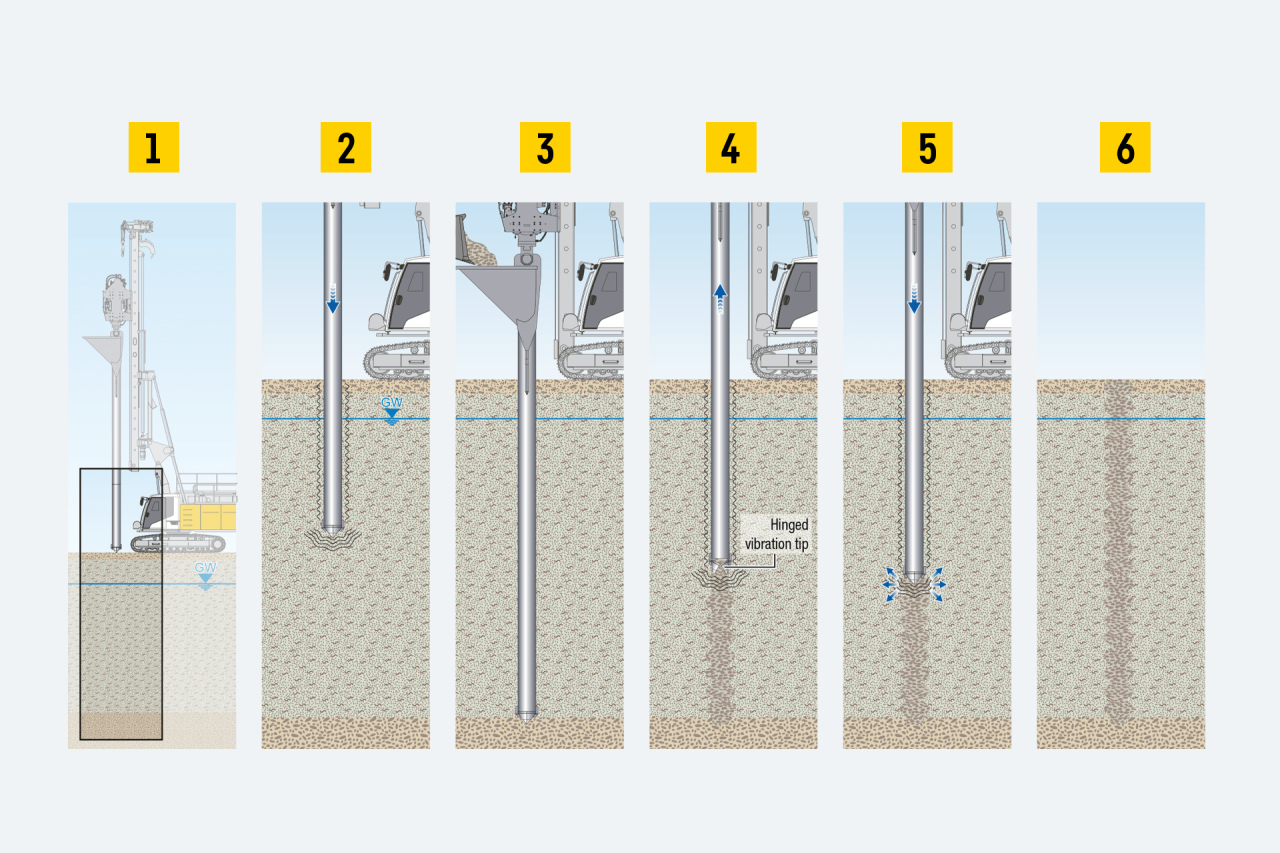

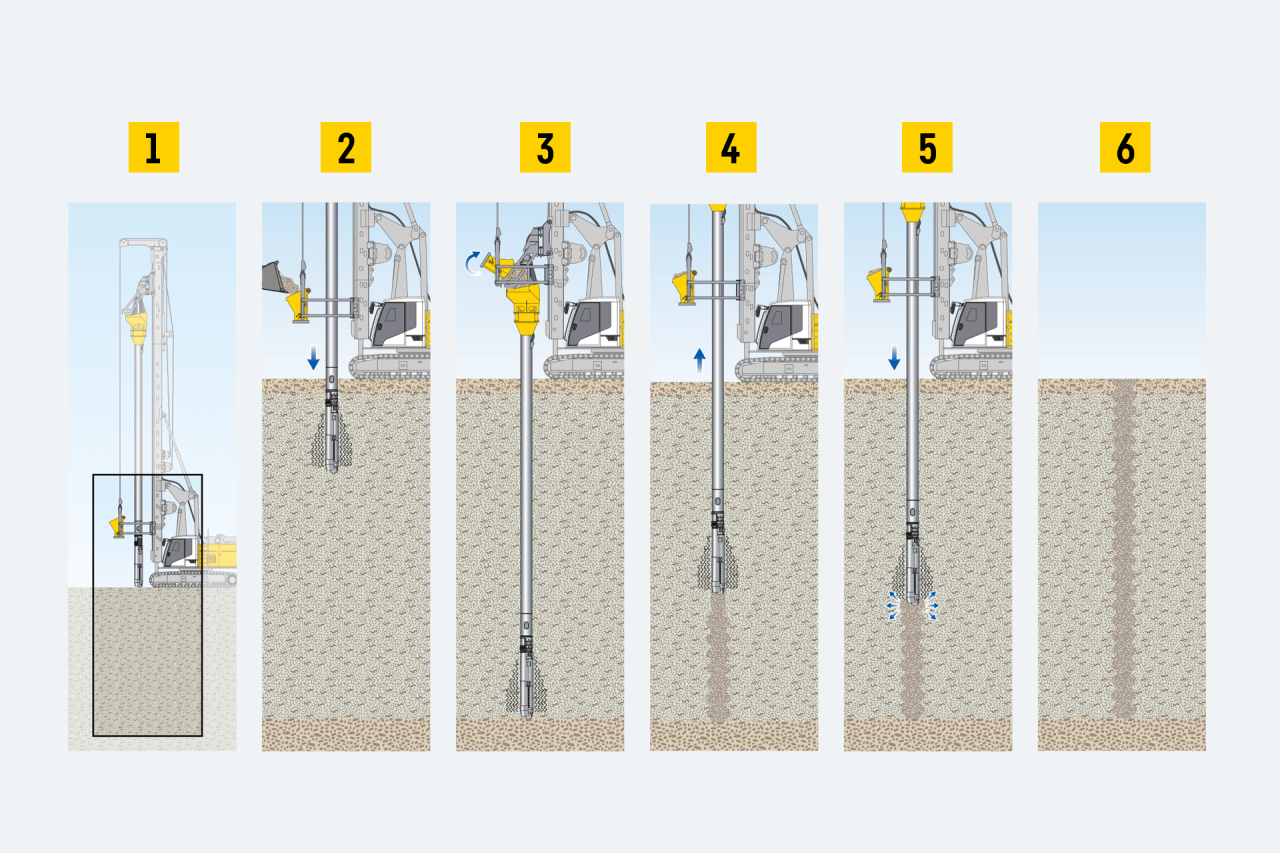

Vibro-replacement is used to improve cohesive soil types. Thereby, coarse extraneous material is filled into the vibrating hopper and a load-bearing gravel or crushed stone column is produced. If the crushed stone columns are arranged in a grid the building ground can be improved area-wide.

01/02

Animation: Deep compaction with the vibro-replacement method

Vibro-Assistant

01/07

Video: Vibro-replacement

The video shows an LB 24 rotary drilling rig in operation with a deep vibrator mounted on the leader.

Machines

Results 1-2 of 3

1

2