SkiveFinishing®

SkiveFinishing®: Innovative and precise

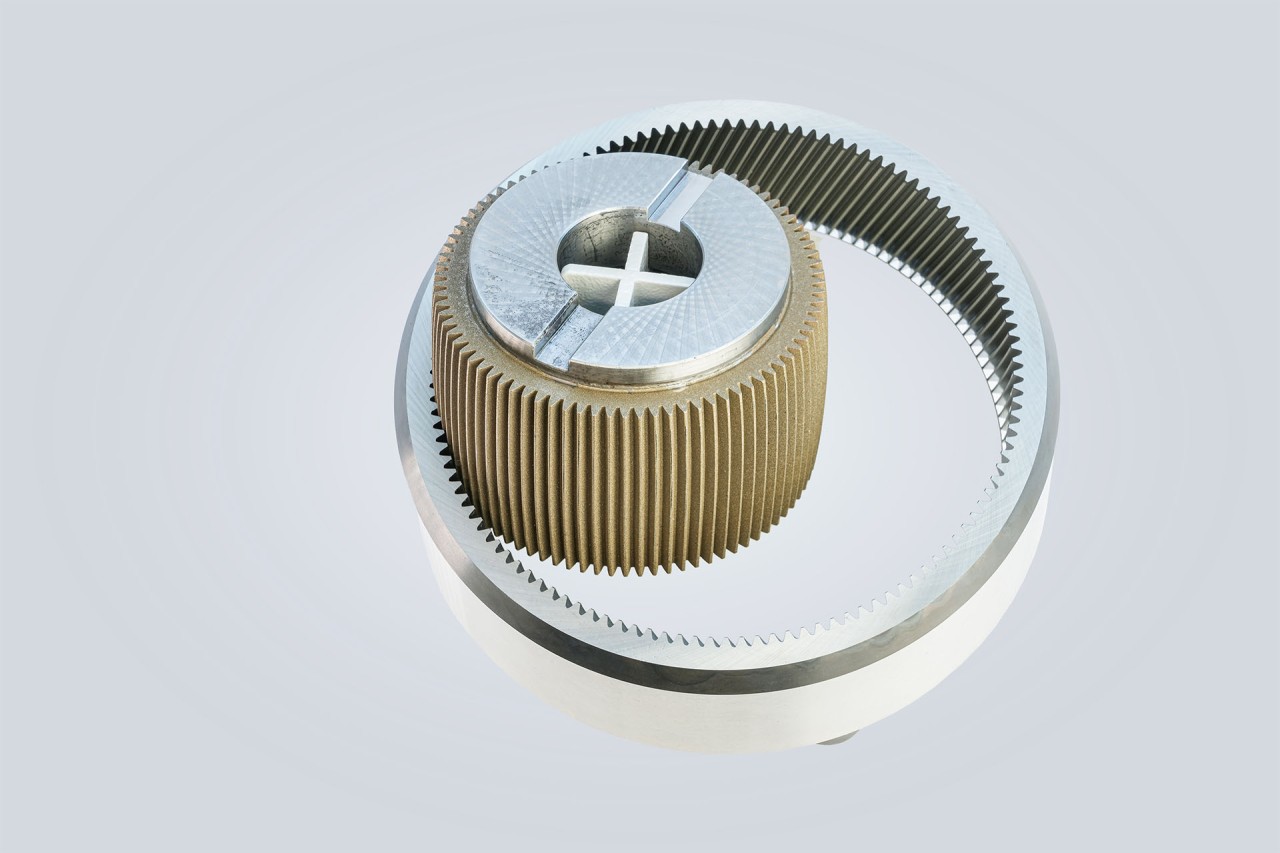

SkiveFinishing® is a new method for efficiently hard machining high quality internal gears. It combines the flexibility of gear skiving with the advantages of non-dressable CBN tools. An innovative CBN tool by Liebherr-Verzahntechnik GmbH ensures a long tool life and even enables profile modification.

Up to now, two methods have been used in hard-fine machining internal gears. Firstly, hard skiving with a geometrically defined cutting edge, which – while economical – comes up against its limits when maximum quality is required. Secondly, profile grinding with a geometrically undefined cutting edge, which offers maximum precision, but is time and cost intensive and therefore only suitable for series production under certain limited conditions, for example in e-mobility or commercial vehicles. SkiveFinishing® fills this gap: It uses the kinematics of gear skiving in combination with a non-dressable electro-plated skiving tool. This achieves higher quality than in hard skiving, but is also faster and more efficient than profile grinding.

Component modifications possible

SkiveFinishing® increases the tooth flank load capacity thanks to the higher residual compressive stresses. Modifications like tip reliefs, profile crowning or tooth trace modifications can also be made directly to the component - even on challenging geometries like internal gears. Previously this was only possible using the costly profile grinding process or a special dressing kinematic process.

If the tool is completely worn, it will be treated at the Ettlingen site. Liebherr’s CBN expertise goes back more than 30 years and so guarantees consistently high quality. This opens up new options for users to optimally adapt manufacturing process to components and economic efficiency.