Generating and profile grinding machines

Gear up!

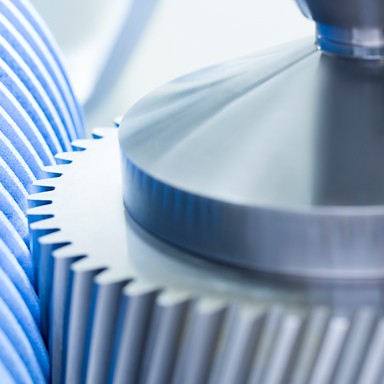

Excellent flexibility for grinding

Liebherr presents generating and profile grinding machines for the hard-fine machining of external and internal gears on workpieces. The demand for high quality gears in areas such as e-mobility come with great challenges. Liebherr is working on the development of solutions for economic manufacturing.

Our generating and profile grinding machines

Evotion

Exciting reports on our generating and profile grinding machines

CBN generating grinding – a thoroughly economic alternative

The demand for high quality gear teeth in areas such as electric mobility, for example, come with great challenges. Liebherr is working on the development of solutions for economic manufacturing.

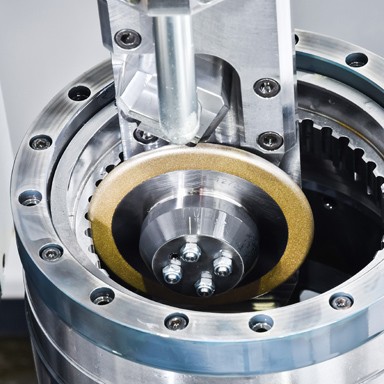

Retrofittable spindle for demanding grinding

Machining gear teeth with interfering contours for the aerospace industry makes huge demands on the grinding tool and often cannot be carried out with standard grinding heads because of the small tool diameters. For such applications, Liebherr has developed a retrofittable spindle which enables demanding aerospace components to be manufactured on already existing LGG gear grinding machines.

Compact and powerful all-rounders

Liebherr presents the new series of generating and profile grinding machines for hard machining of external and internal gears on workpieces with diameters of up to 500 millimeters. The LGG series follows the successful Liebherr LCS 300 to 500 series. With an impressive range of added features, they offer more flexibility and grinding performance with a significantly reduced footprint.

A flexible solution for everything

From the production of satellite antenna systems to medical technology and automation, precision gears are the heart of many applications in industrial production. The automation industry is booming, which means that the demands in terms of both quality and productivity are increasing – a challenge for many providers. Liebherr’s broad range of machines, processes and expertise offers the optimal solution for any application.

30 years and still going strong

More than 30 years ago, Liebherr-Verzahntechnik GmbH introduced the LCS, an innovative gear grinding machine that was the first in the world to allow generating grinding with dressing-free CBN grinding worms. Since then, Liebherr has continued to develop this robust machine through each generation and maintained its position as an international pioneer in gear grinding.