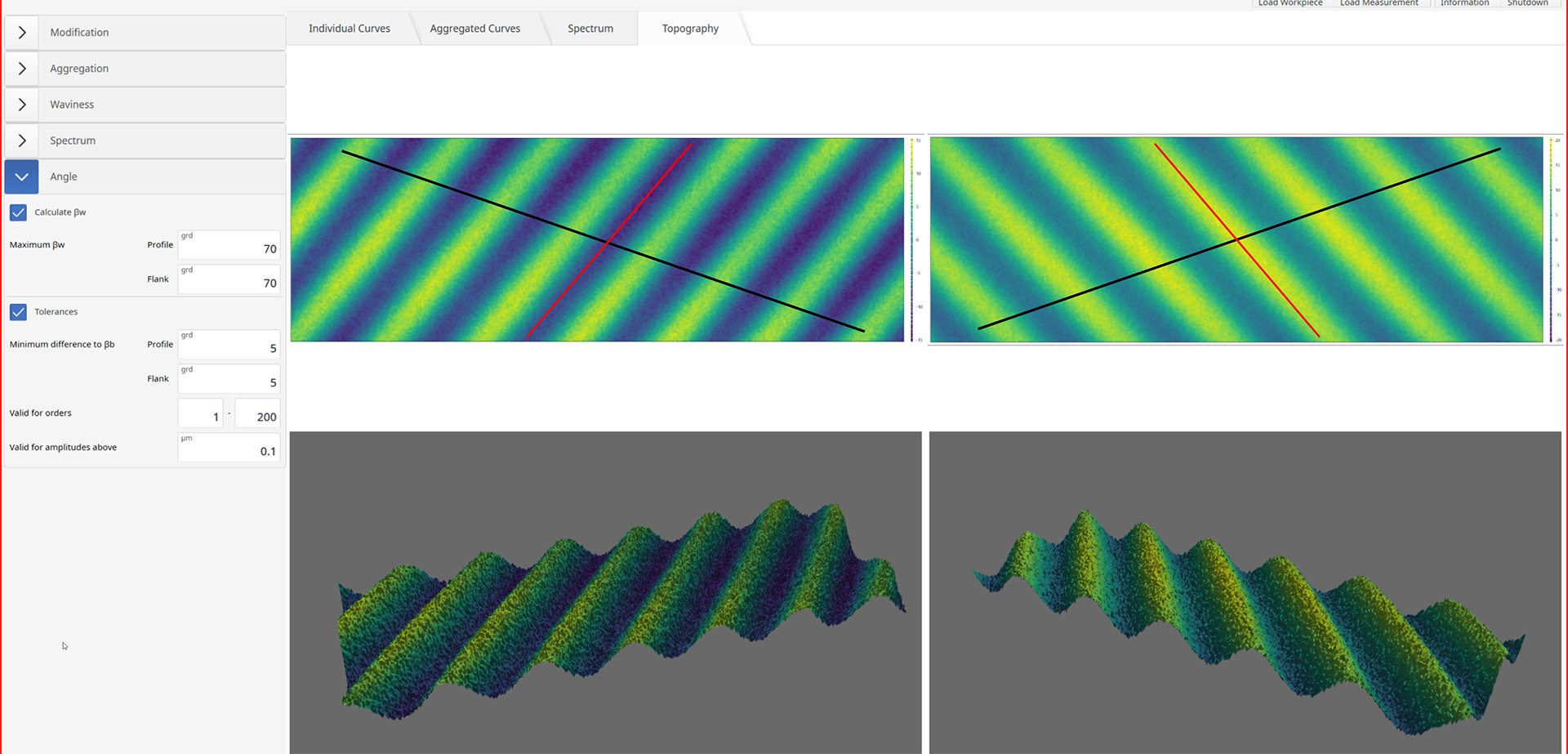

LHEnergyInfo: Quantifying sustainability

The new LHEnergyInfo app from Liebherr-Verzahntechnik GmbH measures and displays energy consumption in production in detail and in real time. As an integral part of the LHWebPlatform, it marks another step forward in the company‘s digitalization strategy.