LHProcessMonitoring and LHFingerprint now even better

The LHProcessMonitoring software monitors and visualizes the manufacturing process. Initially designed for generating grinding and dressing, it now also supports profile grinding and gear skiving. The “digital fingerprint” for machine monitoring was previously available as part of a maintenance contract. Now customers can perform the measurements themselves using the LHFingerprint software.

The earlier deviations in the microgeometry of the tooth flanks are detected, the more effectively subsequent noise emissions can be prevented. LHProcessMonitoring allows you to identify and correct the causes at an early stage. The software visualizes and analyzes process parameters such as torque, axis position, and power, generates dynamic envelopes based on training data, and automatically detects limit violations – before faulty components reach the end-of-line inspection.

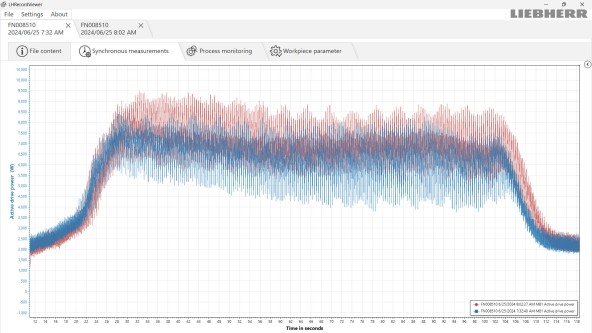

With the ProcessRecordViewer desktop application, all recorded signals can be analyzed in detail, compared and all process parameters comprehensively evaluated.

LHProcessMonitoring optimizes and expands

The software has now been enhanced with new display options and optimized user guidance, and expanded to include profile grinding and gear skiving. With a new tool, ProcessRecordViewer, recorded process data can be visualized and used for data-based production optimization. Originally developed exclusively for our own Development and Technology department, ProcessRecordViewer is now also available to customers offline as a desktop version. “This allows us to meet the needs of many customers who want to build up their own analytical expertise,” explains Florian Schuon.

LHFingerprint facilitates machine diagnostics

An unplanned machine standstill due to a component failure is the worst case scenario for users. Deviations from the machine condition upon delivery are now even easier for customers to identify. The LHFingerprint software has been further developed so that customers can now capture fingerprint data themselves and repeat the recording as often as they wish. These records can also be viewed and analyzed offline in the new ProcessRecordViewer, which underlines the consistency of the Liebherr tool chain.

Recognizing impending standstills in good time

This enables proactive action to be taken during ongoing operations, allowing impending standstills to be identified and avoided at an early stage. Previously, this function was only available as part of a maintenance contract and is now included as a product feature in Condition Monitoring for Liebherr machines.

Three questions for

Florian Schuon,

Head of Digital Solutions at Liebherr-Verzahntechnik GmbH