EMO 2025 – We were there!

EMO 2025 – We were there!

Thank you for visiting EMO 2025!

At EMO 2025, visitors were able to experience pioneering technologies in gear technology and automation systems live. We presented innovative solutions for greater efficiency, precision, and digitalization in manufacturing, and many were inspired!

Press releases

Gear cutting machines

Ready for anything – the LK 280 DC gear skiving machine

LK 280 DC – next-level precision and versatility. Ready for any challenge and more powerful than ever.

The LK 280 DC redefines gear skiving. With its solid machine bed and ultra-rigid workpiece spindle setup, it delivers impressive process reliability, even under the toughest conditions. A standout feature is the integrated LHProcessMonitoring software, which detects changes in the machining process at an early stage, ensuring significantly greater stability. Raw part variations, tool wear and other anomalies are all detected in plenty of time to make corrections. Beyond conventional gear skiving, it also supports hard skiving and the innovative SkiveFinishing® process. This makes it highly versatile and ideal for modern manufacturing requirements.

Optionally, the machine can be equipped with intelligent sensors for real-time analysis of energy, air and coolant consumption via LHEnergyInfo. This reveals potential savings – a genuine bonus for sustainable production and reduced operating costs. Another critical success factor is tooling. We develop and manufacturer our own tools to guarantee the right concept for every workpiece. Our profound process expertise and simulation options guarantee maximum efficiency and quality.

Highlights

- Ultra-rigid machine design for maximum precision

- Direct drives for spindle and table – outstanding dynamic rigidity

- Innovative LHProcessMonitoring software

- Optional chamfering parallel to machining

- Supports hard skiving and SkiveFinishing®

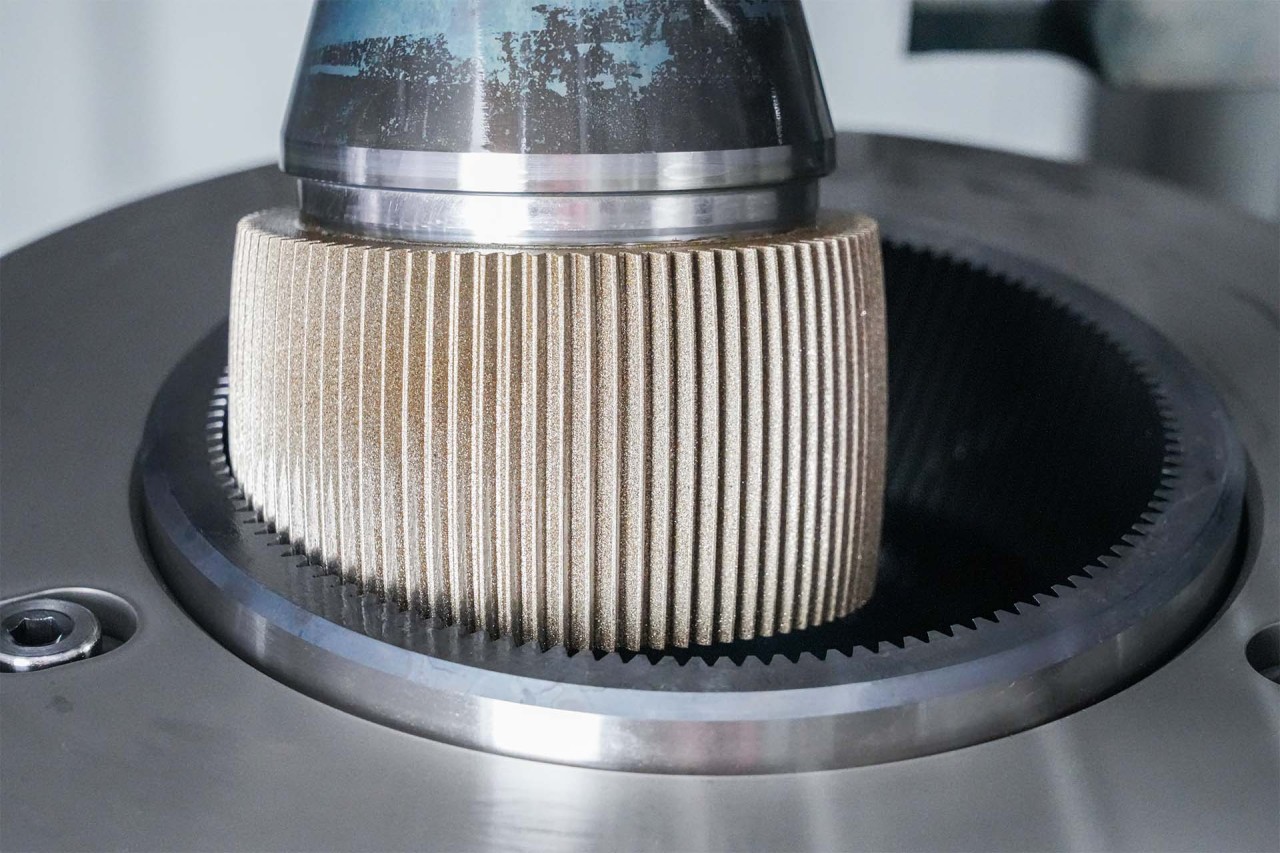

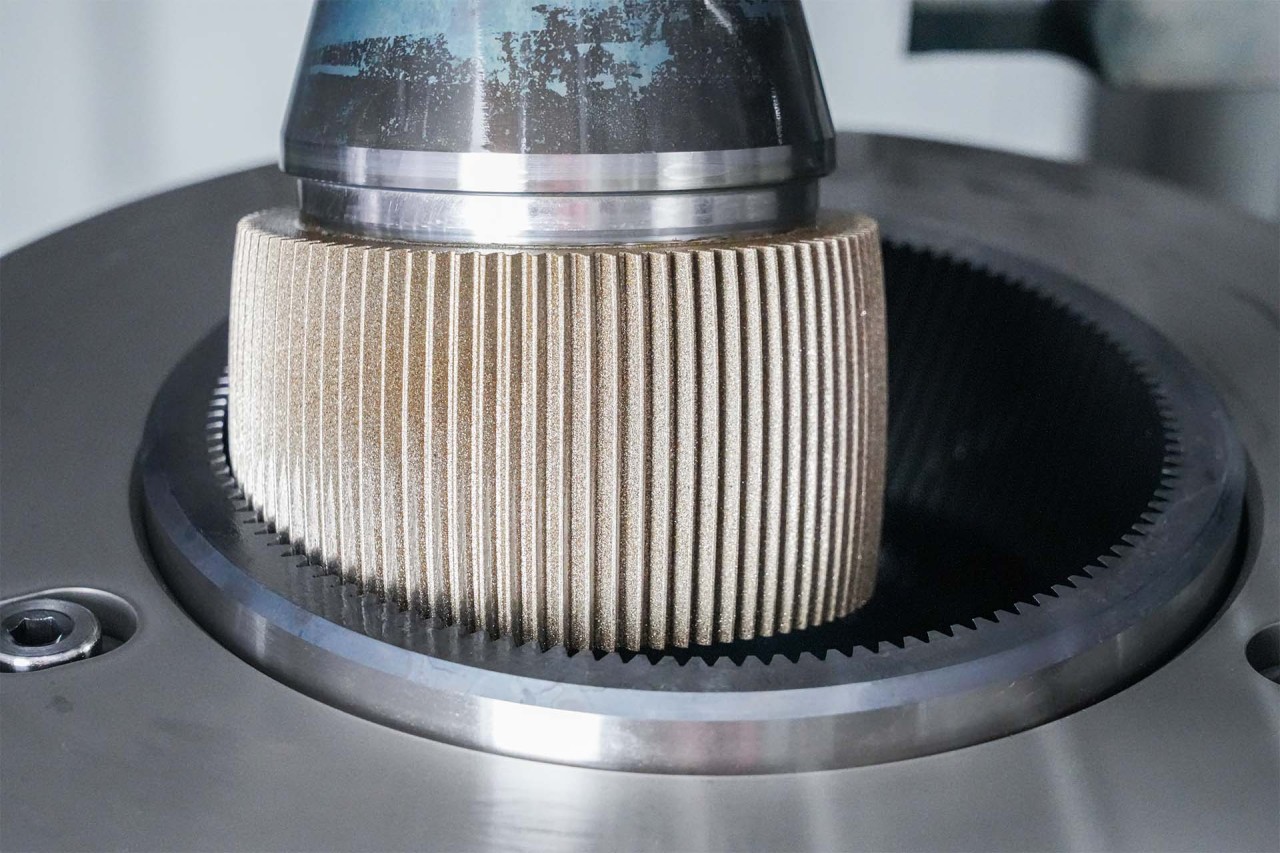

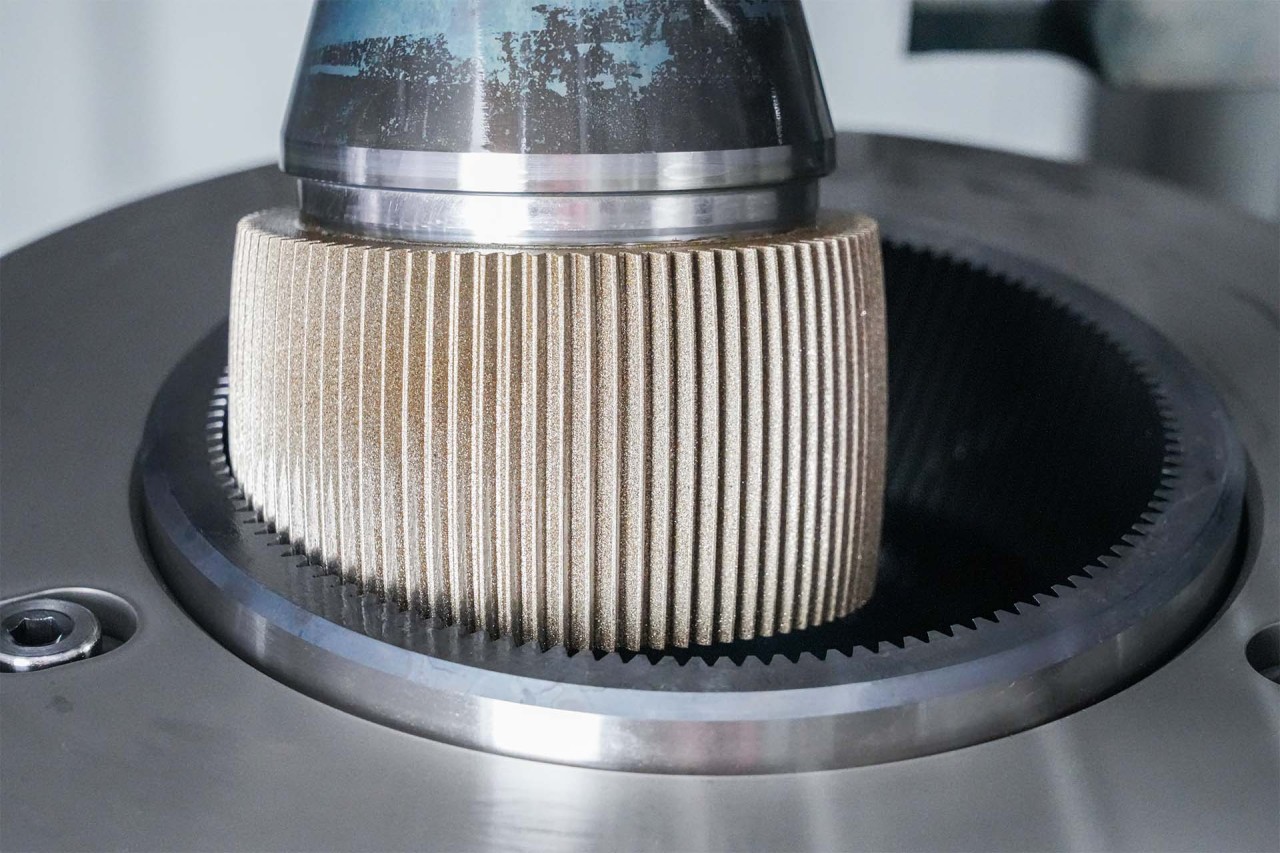

SkiveFinishing® – precision meets efficiency

SkiveFinishing® is an innovative hard finishing process for internal gears that combines the strengths of two proven technologies. SkiveFinishing® merges the flexibility of gear skiving with the advantages of CBN tools that do not need dressing. Optimal surface finishes and highly efficient processes can be achieved by selecting specific CBN grain sizes. Developed by Liebherr-Verzahntechnik GmbH, it fills the gap between fast but less precise hard skiving and highly precise but cost-intensive profile grinding. A newly developed CBN-coated tool with multiple shift positions ensures exceptional process stability, extended tool life and the ability to correct profiles. This makes SkiveFinishing® ideal for industries with demanding quality requirements and strong cost pressures – such as aerospace, e-mobility, and commercial vehicles.

Highlights

- Combination of gear skiving and CBN grinding

- Combines flexibility and precision in a single process.

- Innovative CBN tool design

- Crowned geometry with multiple shift positions for extended tool life.

- Higher quality than hard skiving, more economical than profile grinding

- Ideal for series production with high quality requirements.

- Modifications possible directly on the component

- Allows adjustments such as tip relief, profile crowning and tooth trace modifications.

- Improved load capacity through compressive residual stresses

- Especially advantageous for heavy-duty gears.

- Reconditioning for sustainable tooling

- Reconditioning at the Liebherr facility in Ettlingen ensures consistent quality.

- Broad range of applications

- Aerospace, e-mobility, commercial vehicles – wherever precision and efficiency are required.

World premiere: The new LGP 2000 profile grinding machine

With the LGP 2000, we present a new generation of machines for profile grinding. The modular platform allows efficient machining of workpieces up to 2,000 mm in diameter and sets new standards in component precision and flexibility as well as machine productivity. The thermo-symmetric machine bed with integrated coolant circulation ensures outstanding thermal stability. A hydrostatic bearing table with direct drive guarantees wear-free precision over a long service life. A unique feature is that two grinding discs can be used in sequence without changing tools – allowing either shorter cycle times or higher surface quality, or an optimized combination of both these advantages. The LGP is ideal for high-speed grinding, creep feed grinding and single- or double-flank topological grinding. For ultra-precise machining of internal gears, an optional grinding arm is available.

Highlights

- Profile grinding up to 2,000 mm diameter – ideal for large gears

- Modular machine concept – flexible, economical, future-proof

- Two grinding discs without tool change – shorter cycle times and higher productivity

- Thermo-symmetric machine bed – maximum thermal stability

- Prepared automation for pallet changer or ringloader

New LC 2000 gear hobbing machine

The new LC 2000 gear hobbing machine is based on the same platform as the LGP 2000 profile grinding machine. The new series caters for all relevant gearmaking technologies and is aimed at manufacturers of large gears, particularly for industrial machinery, marine propulsion, construction machinery and wind power. The platform allows machining of workpieces up to 2,000 mm in diameter and sets new standards for precision, flexibility and productivity. The thermo-symmetric machine bed with integrated coolant circulation ensures outstanding thermal stability. A hydrostatic bearing table with direct drive guarantees wear-free precision over a long service life. The machine can be optionally equipped with an integrated FlexChamfer unit for deburring and chamfering. The optimized chip removal is ideal for wet and dry machining. The chip removal has also been optimized for milling internal gears, eliminating the need for a complex, separate chip removal duct in the floor foundation.

Highlights

- Gear hobbing up to 2,000 mm diameter – ideal for large gears

- Modular machine concept – flexible, economical, future-proof

- Thermo-symmetric machine bed – maximum thermal stability

- FlexChamfer unit – economical even for small production runs

- Prepared automation for pallet changer or ringloader

LGG 300/380/500 generating gear grinding machine

The LGG series combines the three technologies of generating, profile and internal grinding in one machine. Thanks to this technological diversity, Liebherr offers the universal user maximum benefit and a secure investment for the future. The machine can be configured for the individual application. This can be done, for example, by an external automation system using a plastic chain conveyor or robot automation. The LGG is also the most powerful generating gear grinding machine in its class on the market. With the GH 320 CB gear skiving head, workpieces up to module 14 mm can be very economically machined to excellent quality. The extended travel ranges allow the machining of long shafts and at the same time improve the internal grinding of deep workpieces.

DIP – Dresser independent profile modifications

DIP is a versatile generating grinding method specially developed by Liebherr that uses dressable grinding worms. It allows profile modification on the workpiece when using profile rolls in the dressing process. In particular, profile angle modifications, crowning, as well as tip and root reliefs can be precisely specified and ground. It offers the advantage that using profile rolls makes the dressing process many times faster, and the surface of the worm is the same as for typical series production.

LHProcessMonitoring

Inline process monitoring with LHProcessMonitoring

The LHProcessMonitoring software from Liebherr-Verzahntechnik GmbH for inline process monitoring visualises the production process and uses the training data to determine limit values for monitoring the production process. This way, deviations that could lead to noise abnormalities can be identified. The software is optionally available as part of the LHGearTec operating and programming interface, making it a consistent continuation and expansion of our digitalisation product portfolio.

With continuous recording and transparent evaluation, the software enables the operator to optimise and stabilise the manufacturing process. Limit violations are automatically detected to prevent the affected components from entering the subsequent process. LHProcessMonitoring ensures the consistent quality of every individual gear and can be used instead of full downstream testing with a single flank check system or master gear, thus saving investment and set-up costs for comparatively little outlay.

Digitalization solutions

Customized digitalization solutions for your requirements

Customized digitalization solutions for your requirements

With a combination of data profiles, protocols and the LHWeb-Platform, Liebherr provides an infrastructure for the acquisition, transmission, storage, processing, provision and display of machine, operating and production data. In the basic app LHMachine-Info, users can see the live status of their machine tools at a glance and observe changes in real time. The LHSignalInfo app visualizes the recorded signals, taking into account all measuring points and their exact time stamp. The LHReportInfo app visualizes and analyzes the performance of the machine and generates reports and evaluations from the machine data – a decisive step toward more productivity.

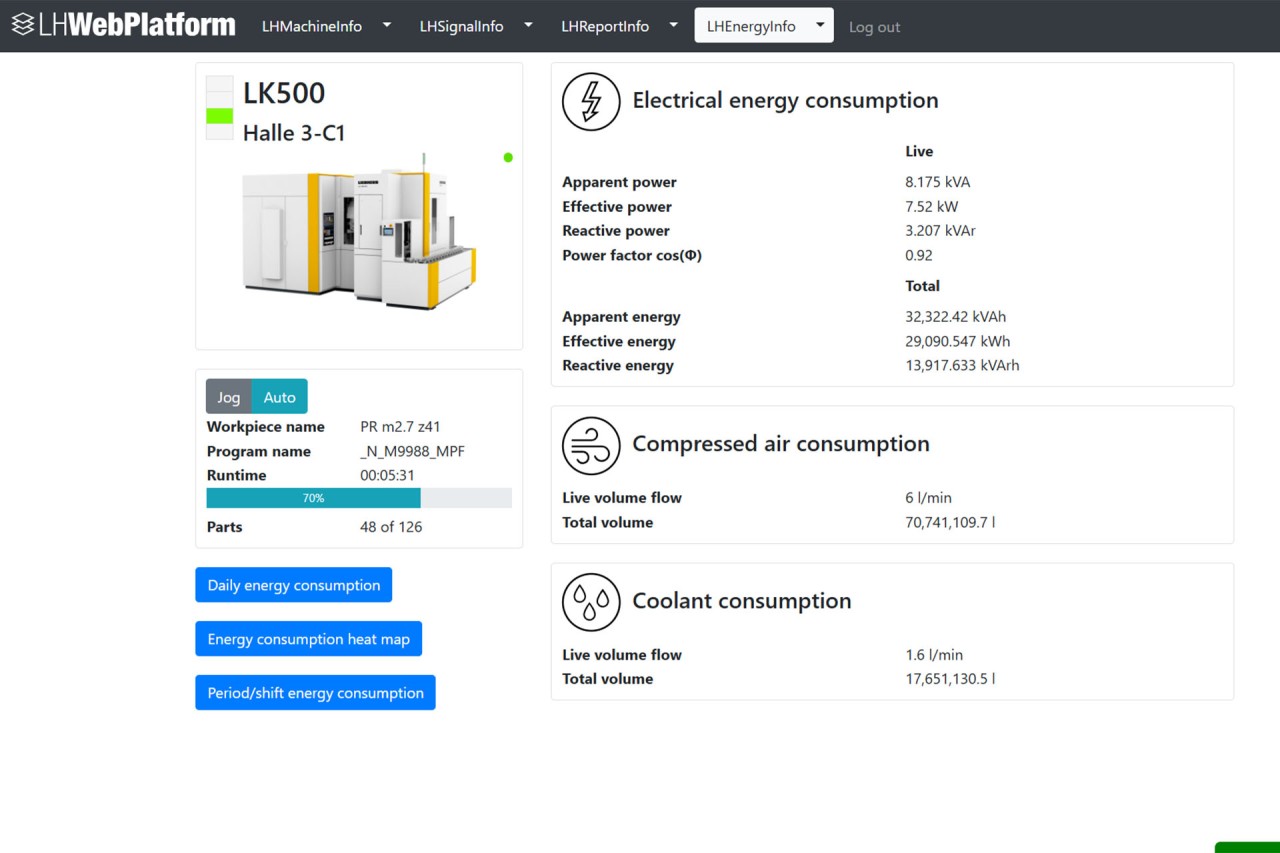

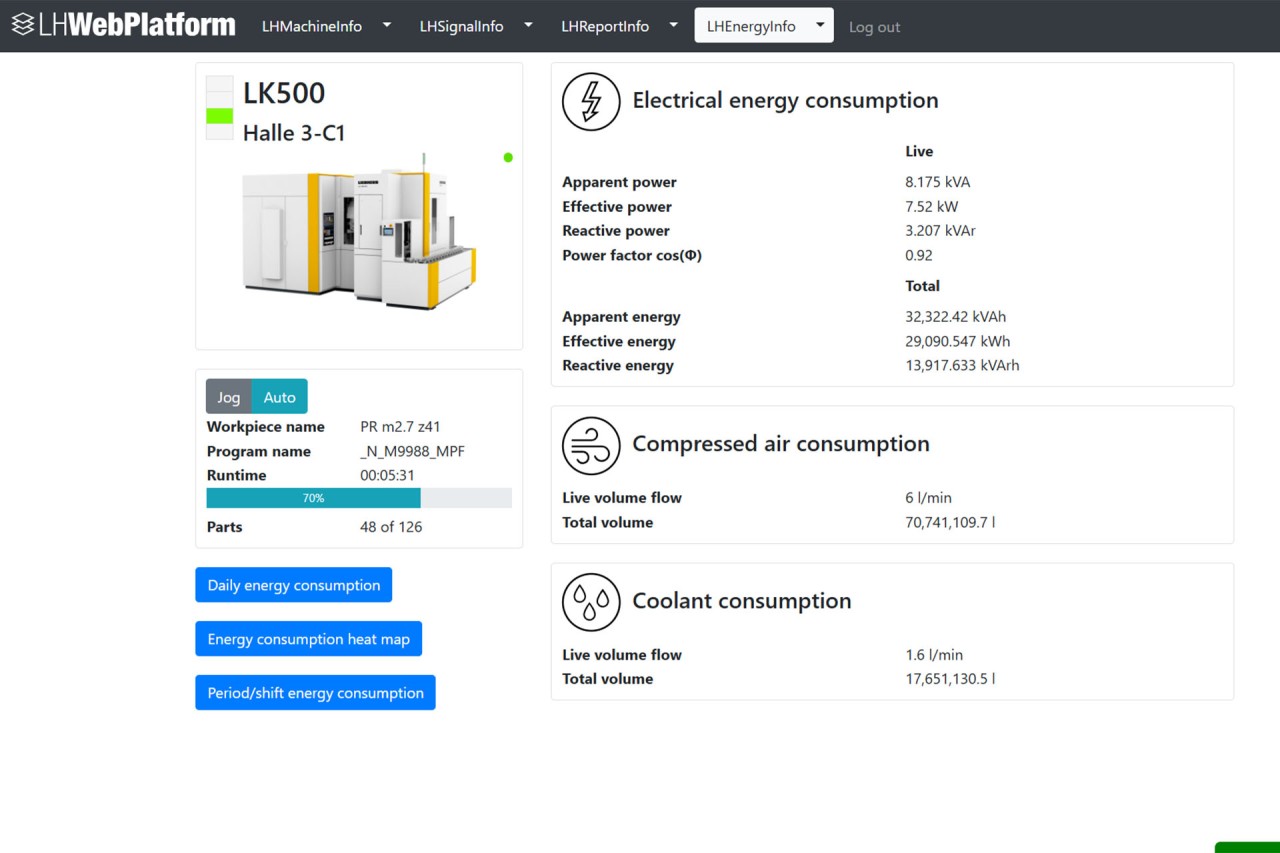

LHEnergyInfo – transparent, workpiece-specific energy consumption monitoring

This year sees the launch of LHEnergyInfo, a new app for accurately recording and visualizing energy consumption in production. As part of the LHWebPlatform, it delivers real-time data on electricity, compressed air and cooling lubricant consumption for each machine, shift and even workpiece. The app provides complete transparency, including auxiliary consumption during standby or when control voltage is active. An intuitive heatmap instantly reveals load peaks and opportunities to save energy. This means processes can be optimized, energy costs reduced and CO₂ can be tracked for individual components.

LHEnergyInfo supports sustainable manufacturing strategies, helps ensure regulatory compliance and qualifies for funding under Industry 5.0 initiatives.

LHWebPlatform apps at a glanceModular toolbox for digitalization: Data profiles: Basic, Production, Process, LHGT Data Extension interfaces: OPC UA, MT Connect, MQTT, umati

Core apps

- LHMachineInfo – live machine status dashboard

- LHSignalInfo – analysis of machine signals

- LHReportInfo – reports on utilization, downtimes, alarms

- LHEnergyInfo – energy consumption per machine and workpiece

Gear cutting tools

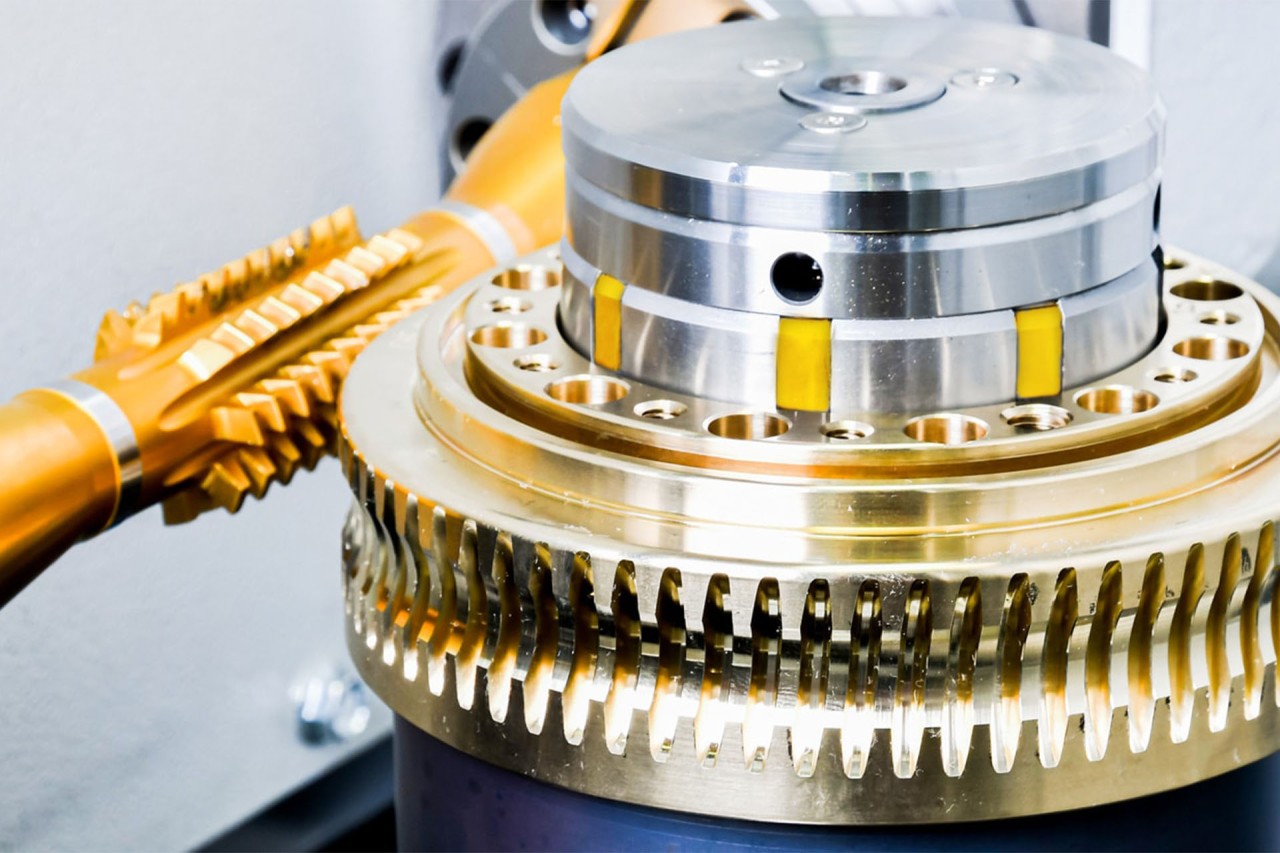

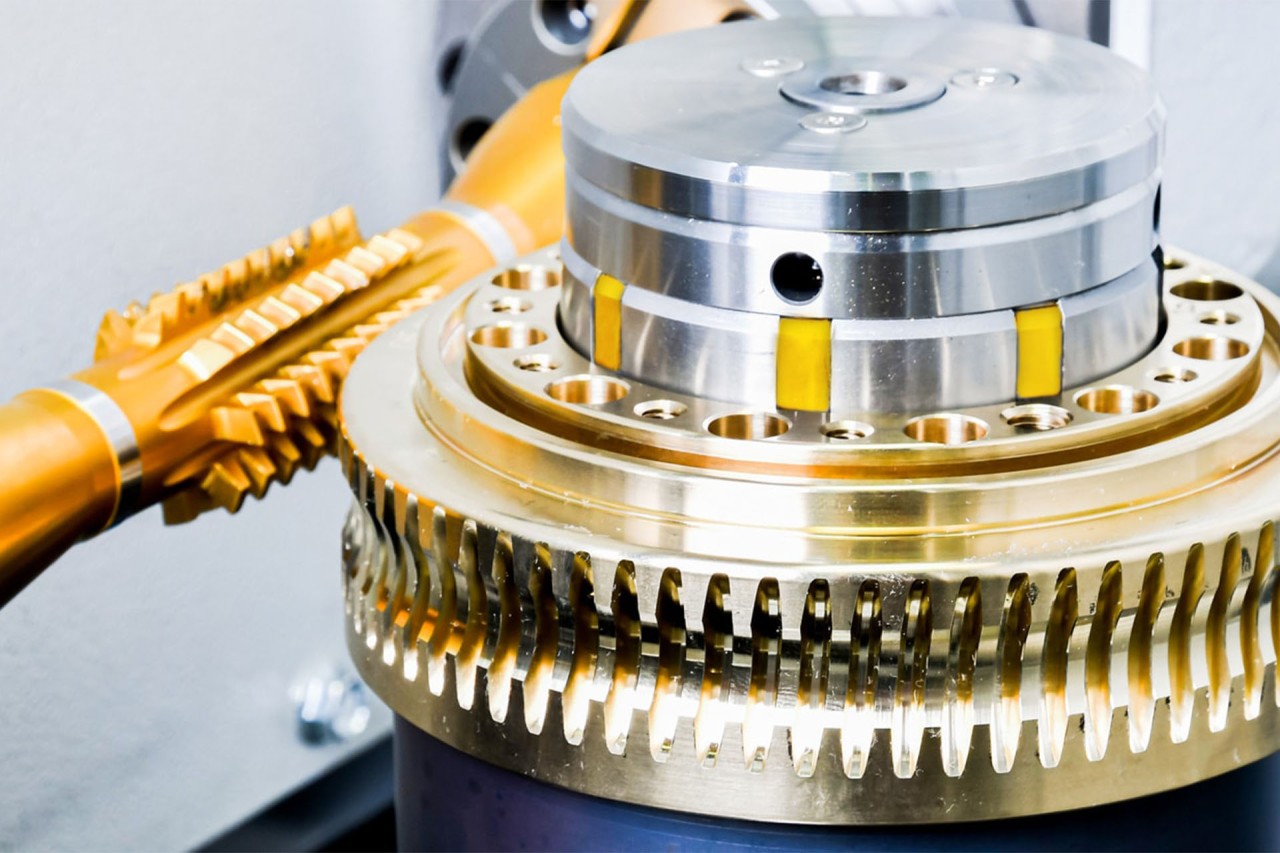

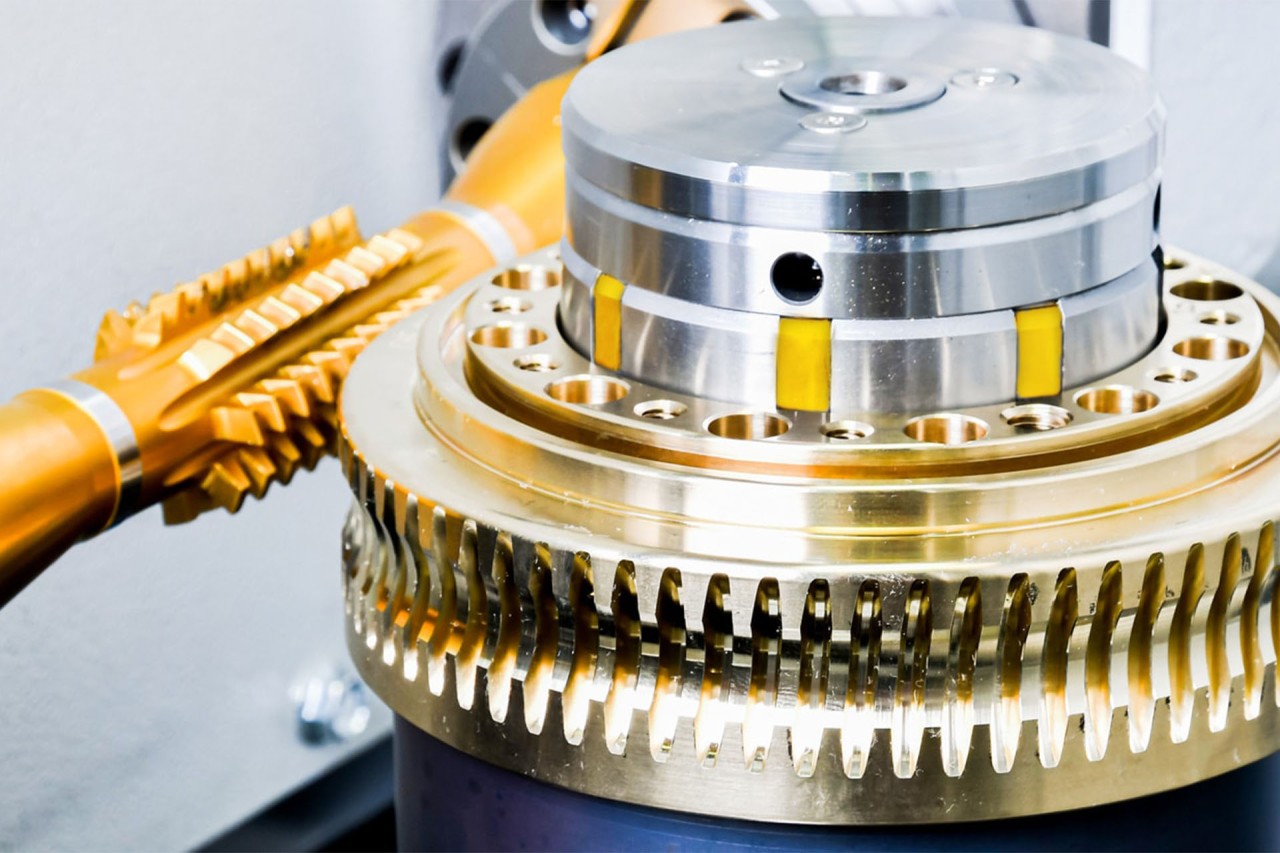

Holistic technological competence with Skiving³

The success of gear skiving lies in the significantly higher efficiency and productivity of this process compared with shaping and the considerably higher flexibility and lower investment compared with broaching. Liebherr knows the entire process of gear skiving profoundly. We have combined all of our expertise concerning tool design, machines, and technology of gear skiving in the Skiving³ technology package. Very high accuracy in tool production, coupled with optimal tool design, guarantees an excellent gear quality and long tool life. Liebherr guarantees the reliability of its manufacturing process at the highest quality level. The gear skiving tools are available in tapered and cylindrical form and can be optionally manufactured from powder-metallurgical high-speed steel (PM-HSS) or full carbide.

The combination of axial crossing angle, cutting speed, feeding, and other kinematic parameters make the method very flexible: Particularly for internal gears in medium batch sizes and external gears with an interfering contour, gear skiving is an additional “ace up your sleeve” in the gear cutting range.

Highlights

- Optimal tool design

- Best quality: High level of accuracy and long tool life

- Short delivery times and process support

Our location at EMO – How to find us!

SECLA – segment clamping arbor

Everything from one source with the right clamping technology

We have expanded our successful and proven clamping concept to accommodate diameters of up to 245 mm. Our precision SECLA segment clamping arbor is increasingly being used, even for large workpieces, as it ideally meets the requirements. Clamping solutions for gear manufacturing machining are usually very individual and have special requirements regarding concentricity and interfering contours. For this reason, it is particularly important to find the right clamping device for the application. Liebherr therefore provides its customers with a specially developed clamping device within ten weeks.

Using segment clamping technology, reliable and precise clamping of the workpieces from the bore can be achieved. The segment clamping arbors can be used universally. They also offer further advantages compared to standard segment clamping arbors. Conventional systems often reach their limits, for example with small workpieces with interfering contours – for Liebherr’s SECLA, this is no problem!

SECLA segment clamping arbor in figures

- Ten sizes for the clamping range from 20 to 245 mm

- Concentricity < 5 µm

- At least 250,000 clamping cycles

Highlights

- Fast availability and everything from one source

- Ideal interfering contour with maximum rigidity

- Highest concentricity and axial runout accuracy

- Simple and fast changeover

- Integrated rinsing solution for air and oil to remove chips

Measuring machines LMC

Are you looking for a solution to ensure quality and increase productivity in gear manufacturing?

The four-axis measuring instruments of the LMC series have high-precision mechanics and electronics, which are controlled by smart and user-friendly software. They meet all accuracy re-quirements regarding gear measurement and comply with VDI guideline VDI/VDE 2613, group 1.

In addition to the gear inspection machine options available as standard, customer-specific solutions are also available, such as adjusting the travel range on the Z-axis, longer tailstocks to accommodate long shafts, and rotary tables adapted to the payload. An automatic sensor changing system ensures uninterrupted measurement of the workpieces and also offers the highest levels of convenience for the user.

The extensive software features make the machines suitable for measuring all types of gears, such as spur gears, bevel gears, worms, worm gears, shafts, gear cutting tools, and other rotationally symmetrical parts.

Highlights

- Waviness analysis 2.0 for more precise gear noise analysis

- Highest precision provided by granite guides and air cushioning

- Low operating costs due to contactless guides and reliable probes as well as inexpensive spare parts

- Flexible for all types of gears

- User-friendly interface and ergonomic design

- Manufacturer-neutral GDE interface for data transmission to production machines

- Highest precision provided by the new roughness sensor

Automation systems

Introducing flexible production automation

Pallet handling systems as a productivity booster

Liebherr pallet handling systems open the door to increased productivity, even for small batches.

Pallet handling systems handle workpieces on uniform transport pallets. This makes them the ideal automation system for one-off and small batch manufacturing, facilitating unmanned shifts through to “lights-out manufacturing” and enabling unit costs to be reduced by up to 40 percent and machine running times increased to up to 90 percent. The application and combination possibilities are diverse.

The rotary loading system provides compact automation for one or two machining centers. The modular PHS Allround can be expanded in one-meter increments and links up to four machines. This means that the front ends of the system can also be used, and attractive options such as front access for machine access without downtimes, or the double loader for even more productivity, are available. The PHS Pro has no upper limit and can automate any number of machines, also with integrated material management.

Highlights

- Three products, suitable for all requirements

- Standard automation with short delivery times as well as a flexible manufacturing system with any degree of automation

- Machine runtime up to 90 %, manufacturing costs -40 %

More flexible, stronger, smarter: The new RLS

The revised version of the RLS rotary loading system is a powerful solution for automated machine loading, now capable of handling workpieces up to 2,000 kg. This new version offers increased storage density, larger interference diameters (up to 1,400 mm) and maximum flexibility with minimal space requirements. The RLS is modular in design and can be tailored precisely to the production environment. It automates loading for up to two machining centers and is ideal as a cost-effective entry point into flexible manufacturing. The lift module automatically stores components in a rotary rack with up to four levels. With its manufacturer-independent design, it can be easily integrated with a wide range of machines.

A standout feature is the redesigned setup station, which now allows precise alignment of workpieces. Options such as electric rotary units and integrated hydraulic clamping further enhance ergonomics and process reliability.

Highlights

- New load class up to 2,000 kg

- Extended interference diameter up to 1,400 mm

- Modular concept for custom configuration

- Compact design with high storage density

- New setup station with precision alignment

- Manufacturer-independent machine integration

- Ideal for flexible, automated production