8 minutes - magazine 02 | 2025

3D planning with Crane Planner 2.0

Planning a heavy lifting operation is often a complex task. And even supposedly simple jobs for mobile and crawler cranes can turn out to be more complex on site than initially envisaged. With Crane Planner 2.0, we’re helping our customers with professional lifting operation planning.

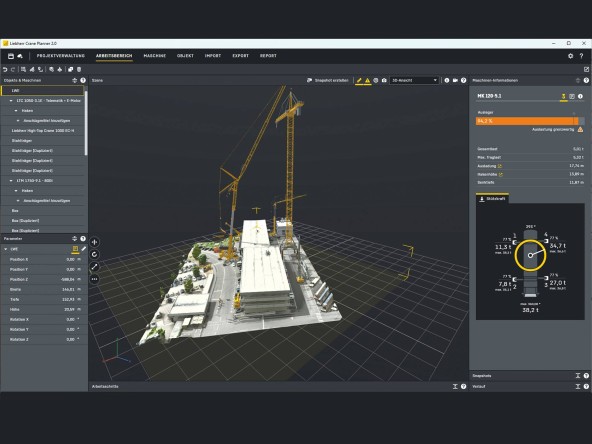

Fantastic tool: 3D planning from drone images in Crane Planner 2.0

This tool enables operations to be prepared efficiently, lifting alternatives to be evaluated and the work subsequently carried out safely and sustainably on the construction site. The often laborious process of entering the exact local conditions into the planning program will become much easier in future: with 3D models of construction sites obtained from hundreds of drone images, planning will be faster and more precise than ever before.

It fits! The 3D model from photogrammetry also provided the dimensions for the entrance gate to the Dalheim monastery. Early in the morning, the LTM 1120-4.1 glides through the gate.

Burkhardt Hartinger is convinced of this. Together with his father and brother, he runs the eponymous crane company based in Warburg near Kassel. Hartinger uses Crane Planner 2.0 pretty intensively. And this gave him the idea of maximising the tools’ advantages with 3D models of the construction sites that he had previously photographed with his drone. Just like recently, when Hartinger was commissioned to lift a small crane in the inner courtyard of a monastery. “Of course, I could have spent hours measuring the monastery building with laser scanners and a theodolite in order to determine the projecting edges and the height of the building. But then I still wouldnʼt have put the data into the planning program,” explains Hartinger. “Instead, I sent my programmed drone to carry out 20 circuits at various heights to capture the entire layout. It took about quarter of an hour. I then sent the 800 or so images to my service provider, got a 3D model in OBJ format back and then imported this into Crane Planner.”

Impressive precision and detail of the images from the imported 3D data in Crane Planner 2.0. Even the smaller trees in the monastery courtyard that cannot be accessed are included in the data. The

Forgotten key – drone unpacked

Hartinger reveals that he has been using the advantages of photogrammetry with the aid of aerial images for two years. “The process is naturally a great help if measurement on site is difficult or complicated.” Sometimes, however, itʼs simply more practical to have this construction site planning option to hand: “One weekend recently, I drove to a planned site to check out the location. Unfortunately I’d left the key for the locked site in the office. So I unpacked my drone and photographed the site from above.” Hartinger smiles, admitting: “Sometimes Iʼm just simply a bit too lazy to do all the measuring myself.”

The transfer of the images from the camera under the pulley head also supports the crane operator when setting down the load.

Crane Planner 2.0 with its 3D data makes it easier for Burkhard Hartinger to send his crane operators perfectly equipped to the job. “Ideally, my crew will find load charts, wind calculations and even support loads in the job planning,” he says. However the best route across the site to the setup area can also be stored there. Or precise instructions for the crane’s support points. Clearance heights and widths for gates can also be determined using the photogrammetric method. It offers many advantages.

Burkhardt Hartinger along with his father Karl and his brother Felix, is joint Managing Director of Karl Hartinger Kranbetrieb GmbH + Co. KG. The company offers its customers far more than just crane and transport services. The portfolio also includes engineering, assembly and façade cleaning. Alongside mobile, crawler cranes and heavy transporters, the extensive fleet also includes SPMTs, working platforms and forklift trucks.

“The biggest advantage, however,” says Hartinger, “comes when the construction site is narrow and the crane has to work with VarioBase®, for instance. And planning the crane support on slopes is significantly easier.” Also, duct and shaft covers, bollards, tree or even kerbs are precisely documented in the 3D data. “This saves my crane operators from so many unpleasant surprises on site.”

How drone shots are integrated seamlessly into Liebherr Crane Planner 2.0

Liebherr’s Crane Planner 2.0 is taking crane planning to a whole new digital level. Even more realistic, even more precise – especially when real site images are integrated as 3D models, as the example from the mission impressively demonstrates. But how does the real world get into the digital planning tool in the first place? The answer lies in the air – or rather, in drones. Such as the ones from Airclip.

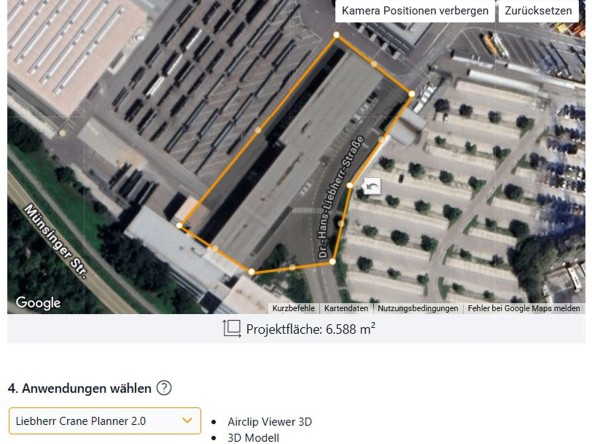

Impressive results:The 3D view of Liebherrʼs administration building was created from 700 drone images. The fly-over for this took just ten minutes.

We wanted to take a really close look at this subject. So we invited Marc Hüfken, Sales Manager at Airclip, to come and see us in Ehingen. He knows the companyʼs history right from the start. Airclip was founded around 15 years ago – originally as a manufacturer of drones. “At the time, the market for drone measurement was virtually non-existent,” Hüfken recalls. “Our background is classical metrology and we came up with the idea early on of offering all-in-one solutions involving drones and photogrammetry software.”

As drone technology became more widespread, our focus shifted: today, Airclip is no longer a manufacturer, but rather a service provider and systems supplier. The company, based in Germany, offers everything from a single source – from the right drone to training and processing of the drone data. Its portfolio also includes drone pilots’ licences and service packages for drone maintenance and repair. For customers from the construction and crane industry, this is a welcome development since it makes moving into the digital 3D world significantly easier.

Demonstration in Ehingen: Marc Hüfken (4th from left) and Marc Angst (HeavyGoods.net) explain to our Product Managers Wolfgang Boos (1st from left) and Andreas Ruf (2nd from left) how a “construction site” can be flown over using a drone to produce usable 3D files.

Complex technology, simple implementation

So how exactly does digital construction site measurement work? First, the area to be flown over is marked out on Google Maps directly on the drone’s remote control. The drone then flies over this route autonomously. “The capture of images usually takes less than 15 minutes,” says Hüfken. The images – simple JPG files – are then uploaded to the Airclip cloud. And this is where the actual magic begins: the photographs are transformed using photogrammetry into a detailed 3D model.

The key advantage for Liebherr customers is that the resulting model is supplied as a ready-to-use OBJ file which has been optimised by Airclip for Liebherr Crane Planner 2.0. This means that it can be imported directly without any further processing into the Liebherr tool.

Results in 24 hours – including quality assurance

Once in the cloud, it takes no more than 24 hours until the finished model is ready. Every data set is checked manually and corrected if required – so the customer gets precisely the result they need. Anyone who registers gets an initial credit voucher worth Euro 50 which can be redeemed on their first project. A follow-on discussion offers personalised tips for future projects.

A simple mouse click: The 3D files can be integrated easily into Crane Planner 2.0 from Liebherr.

Photogrammetry instead of LiDAR: quality meets cost consciousness

The industry often uses the laser scanning technology LiDAR. Marc Hüfken has a clear opinion on this: “Nowadays, photogrammetry is a cost-effective and technologically persuasive alternative.” Although LiDAR delivers very precise data with its point clouds, the technology is more expensive. LiDAR drones start at around Euro 25,000. “With photogrammetry, we are achieving accuracies down to between two and four centimetres now with drones from Euro 900,” says Hüfken.

We asked to see just how easy and efficient this method is for ourselves: an Airclip drone was flown over our administration building at Liebherr and the data digitised. The result? A highly detailed 3D model for the Crane Planner – ready for digital use. We were really impressed. Product Manager Wolfgang Boos: “Of course, the customer can in principle use virtually any drone or photogrammetry software that may be available on the market. However when it comes to a full-service package – especially for beginners – then the Airclip solution is the ideal one to consider in the German-speaking region.”

This article was published in the UpLoad magazine 02 | 2025.