What’s new at Liebherr-Components?

Fairs and events 2024

Innovation without boundaries

- MAWEV SHOW Austria

- World Tunnel Congress

- INTERMAT Paris

- IFAT Munich

- SMM Hamburg

- Mining Indonesia

- MINExpo Las Vegas

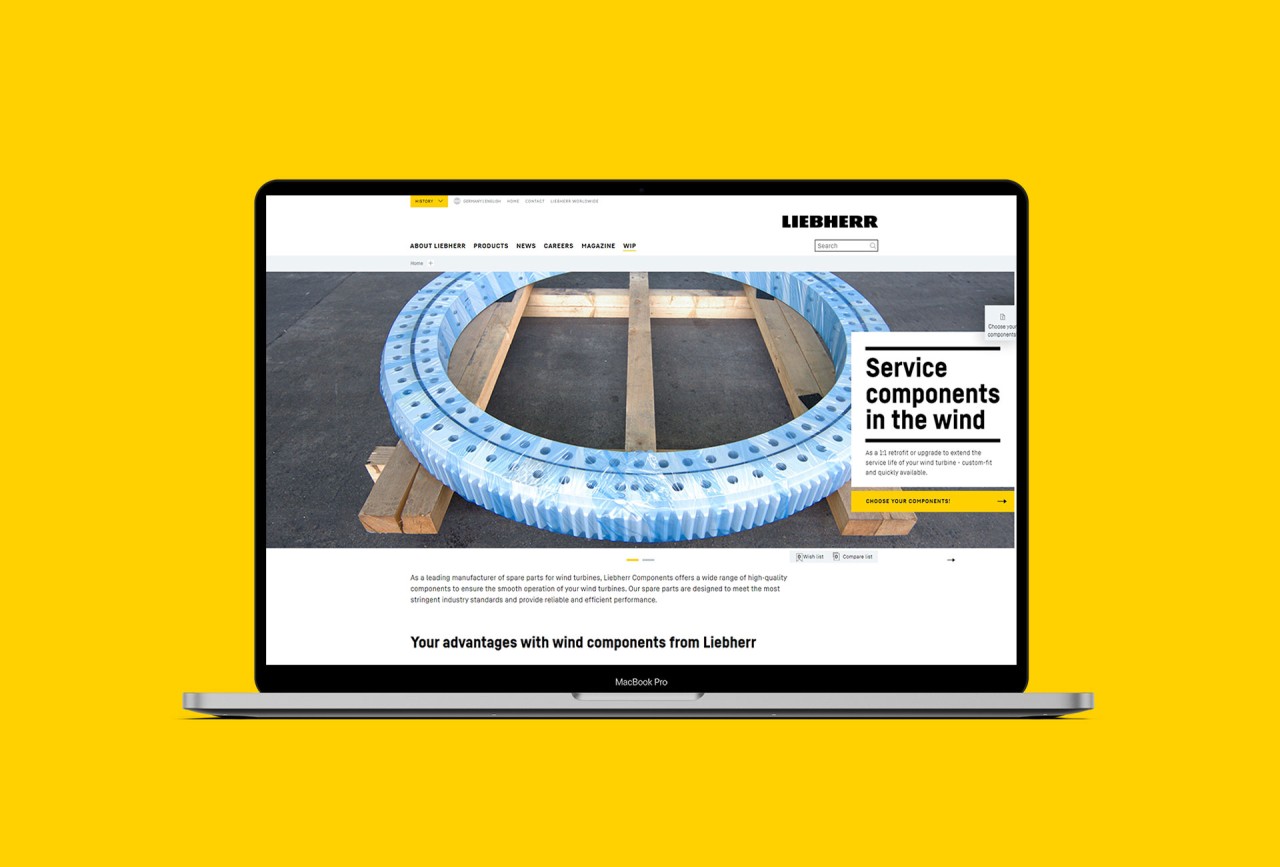

- WindEnergy Hamburg

- China Wind Power

St. Pölten, Austria

From April 10 to 13, 2024

Don`t miss the most exciting construction site in Europe.

Are you ready to marvel construction machinery, trucks and municipal vehicles from various national and international exhibitors? If so, see you there!

Find us in the outdoor area, booth L40

St. Pölten, Austria

From April 10 to 13, 2024

Don`t miss the most exciting construction site in Europe.

Are you ready to marvel construction machinery, trucks and municipal vehicles from various national and international exhibitors? If so, see you there!

Find us in the outdoor area, booth L40

Sign up now!

Stay up-to-date with our latest product highlights and innovative technologies.

Technology & Mining

Technology that lasts

Discover our commitment to enduring technology that excels in the harshest environments and delivers unparalleled precision. In this section, we showcase advancements that redefine durability across various industries.