More about the company

Liebherr careers

Components

Spare parts

Solutions

The global infrastructure of the Liebherr Group offers a wide range of opportunities that are dedicated to serving all of your needs. Our service portfolio includes, but is not limited to the assembly of modules or nacelles. We also develop customer-specific designs to ensure that all components you need are always available.

Topping off our wide range of offerings, our portfolio also features engineering services, digital monitoring during product evaluation and consulting services.

Your challenge. Our solution.

Technologically savvy.

With components in over 25,000 wind turbines installed worldwide and a vast industry know-how, we offer expert advice, construction and design support for your components and systems. Together we develop the ideas of today and apply them in the products and technologies of tomorrow.

Always flexible.

We offer you an all-inclusive package from one single source. Let us win you over with our products, high flexibility and efficient processes.

Competitive.

Benefit from high quality products and a wide range of unique services. With our balanced price-performance ratio, we always go the extra mile for your success.

Our components for your needs.

From the individual components to complete systems, for a green future.

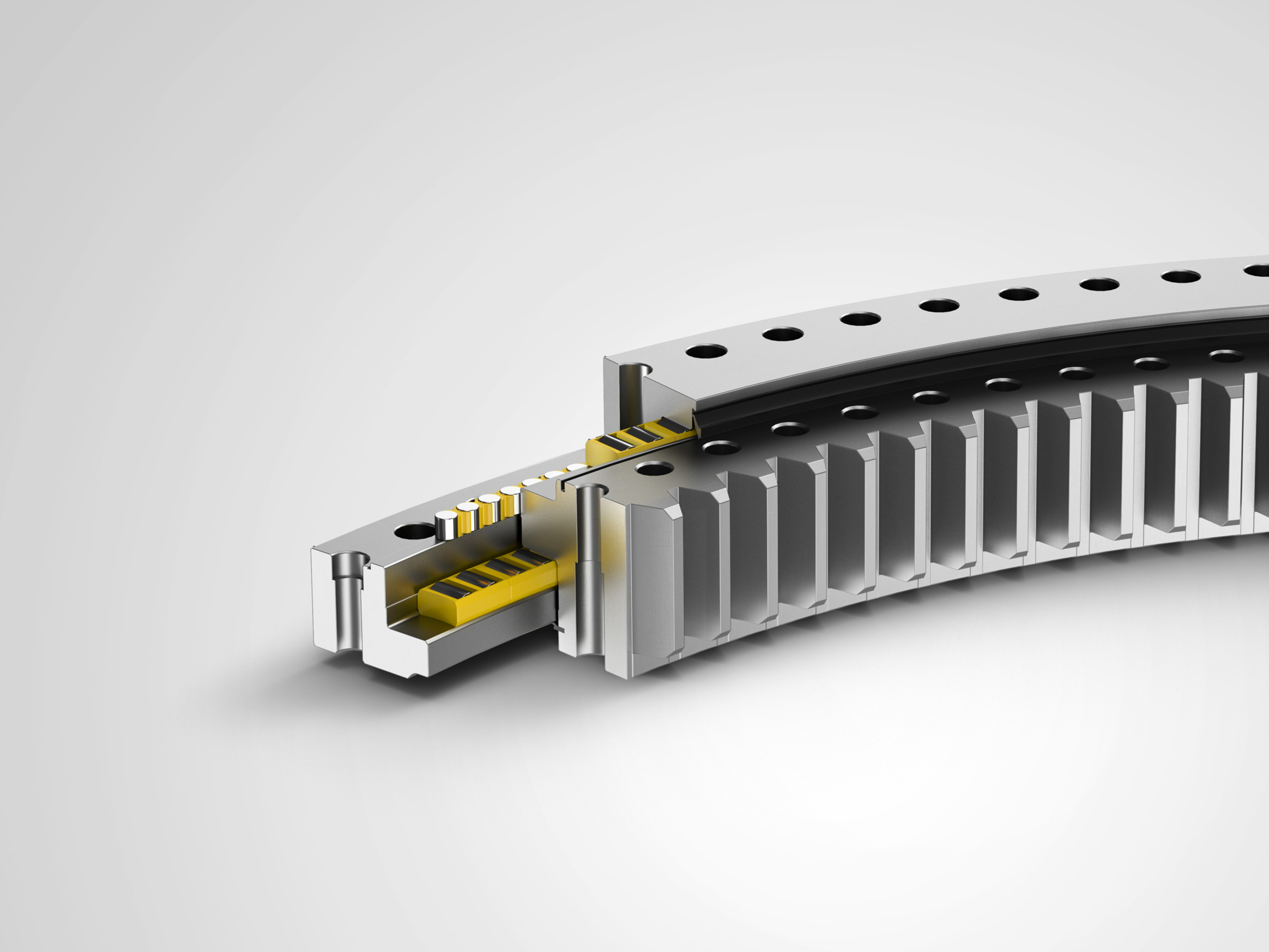

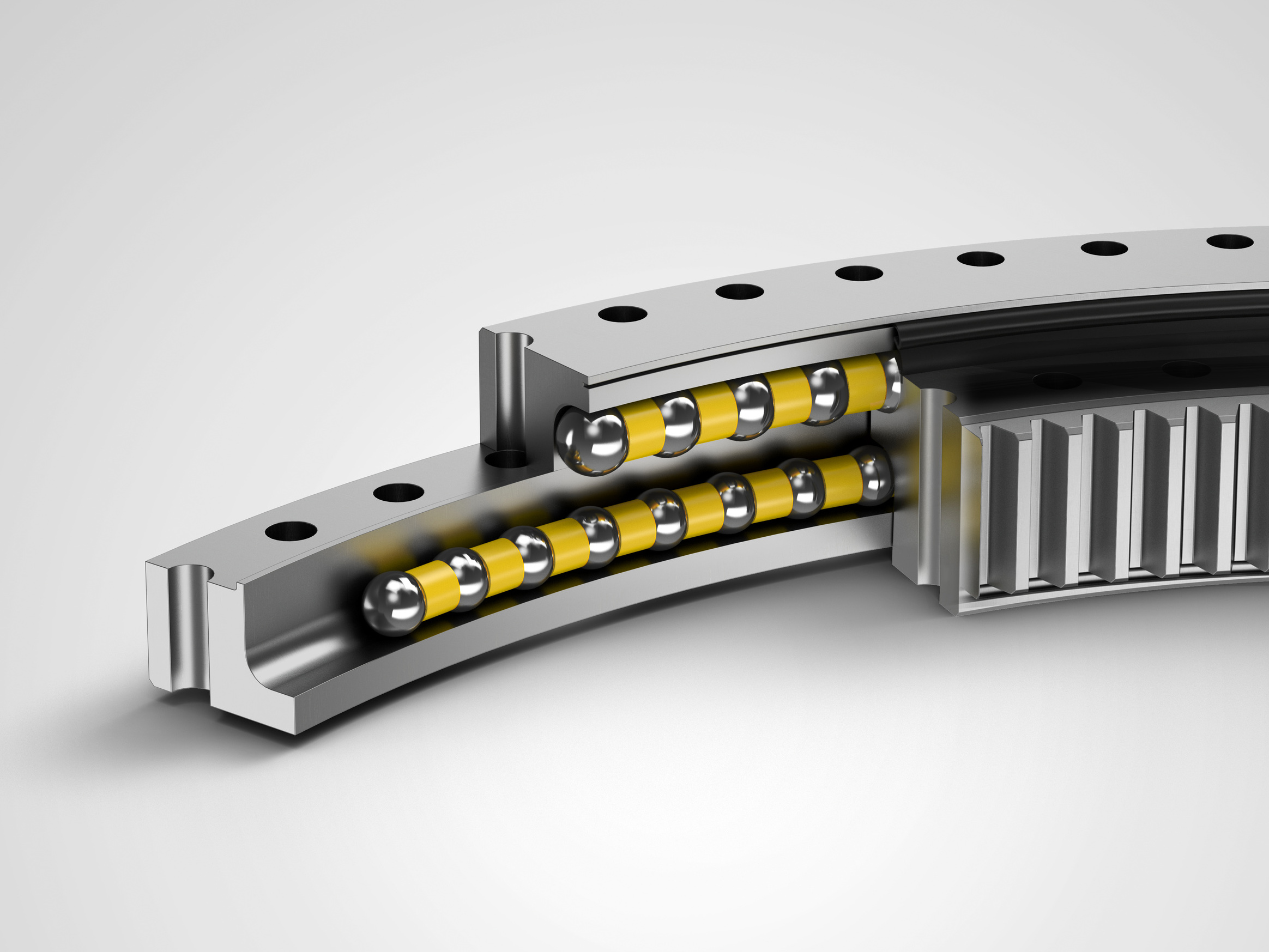

Blade bearings

Increase the durability and productivity of your wind turbine with Liebherr blade bearings. In addition to conventional single and double row four-point bearings, Liebherr also offers 3-row roller blade bearings. This design offers great potential in terms of dimensioning and load absorption or capacity.

Product advantages at a glance:

- fully developed complete systems

- qualified products

- innovative bearing designs

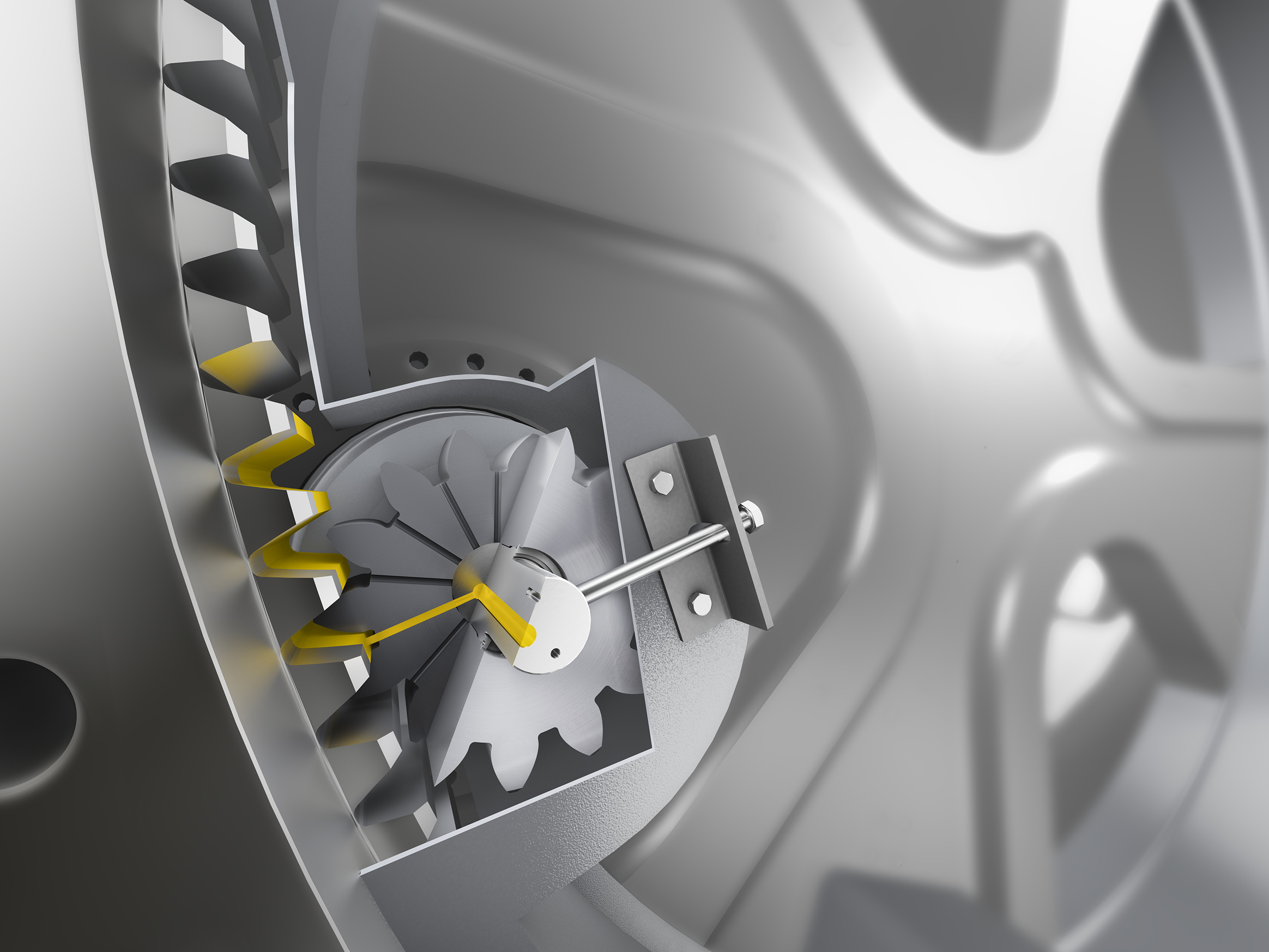

Pitch drives

Robust and low-maintenance: Liebherr pitch drives are particularly durable and outpace most quality standards. With their resilience and long maintenance intervals, they guarantee permanent availability and the best possible energy yield from your wind turbine.

Product advantages at a glance:

- compact design, high power density

- outstanding product quality

- on request: Customisation to customer requirements

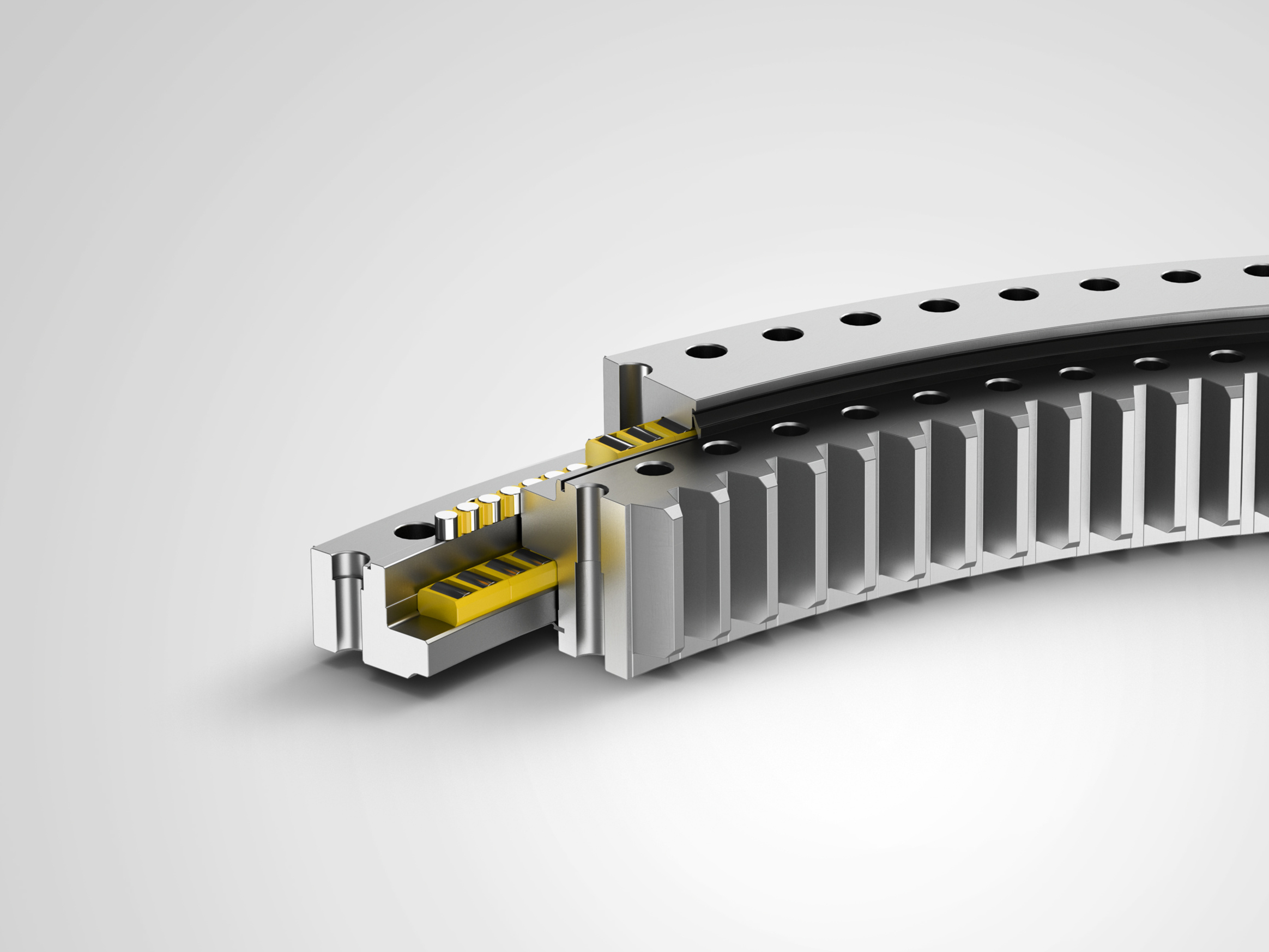

Azimuth bearing

The asymmetrical raceway of Liebherr yaw bearings means they are perfectly designed for swivelling heavy nacelle loads.

Increase the service life of your systems with high-quality and durable yaw bearings from Liebherr.

Product advantages at a glance:

- long service life thanks to optimised bearing design

- high-quality double seals prevent leaks

- extensive service and consulting

Azimuth drives

Keep the nose in the wind: Azimuth (yaw) drives optimally align your nacelle with the prevailing wind direction. With yaw drives from Liebherr, you are choosing high-quality, durable and low-maintenance components that extend the service life of your wind turbine.

Product advantages at a glance:

- compact design, high power density

- outstanding product quality

- on request: Customisation to customer requirements

- Optionally with pre-assembled electric motors

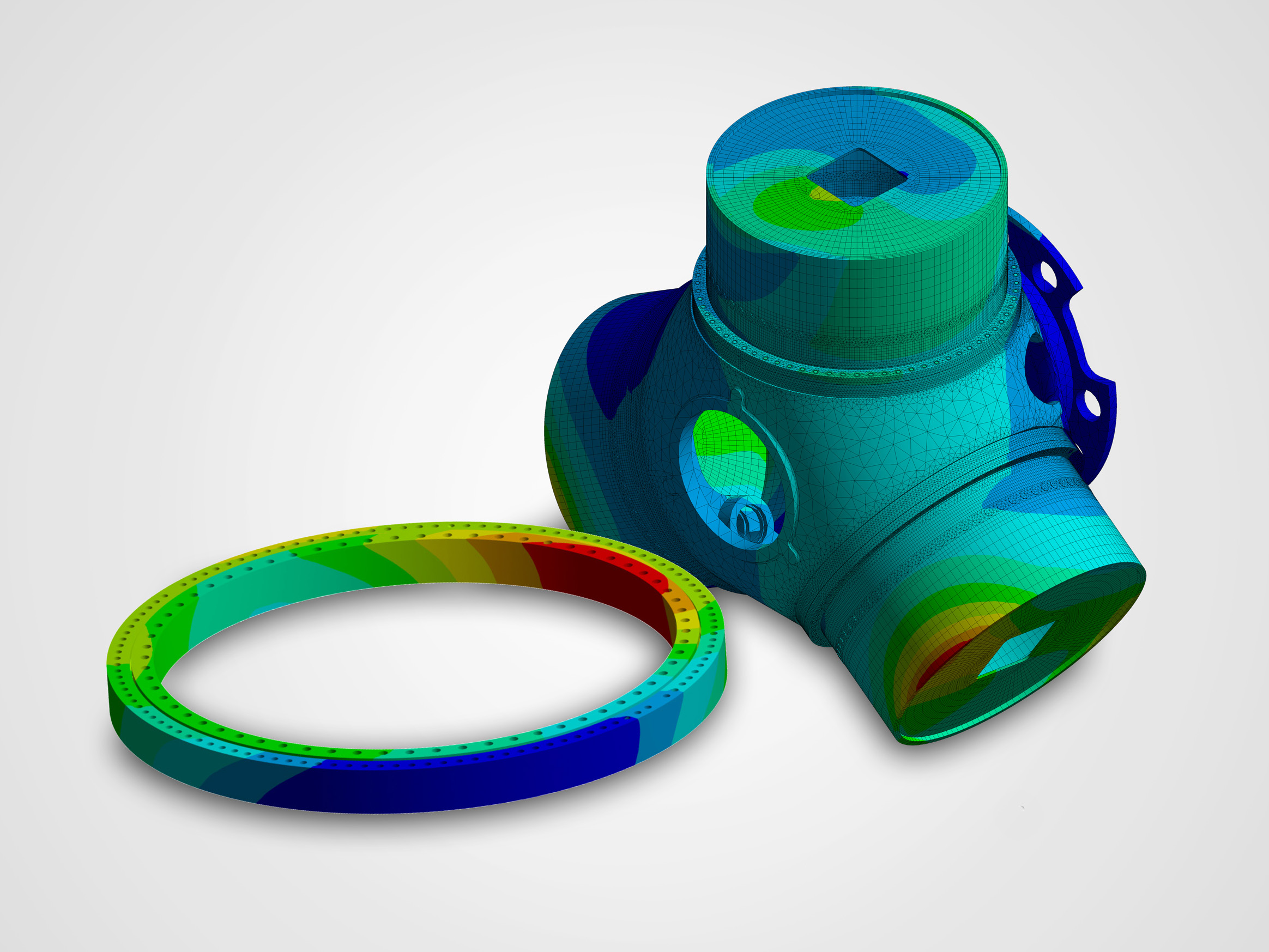

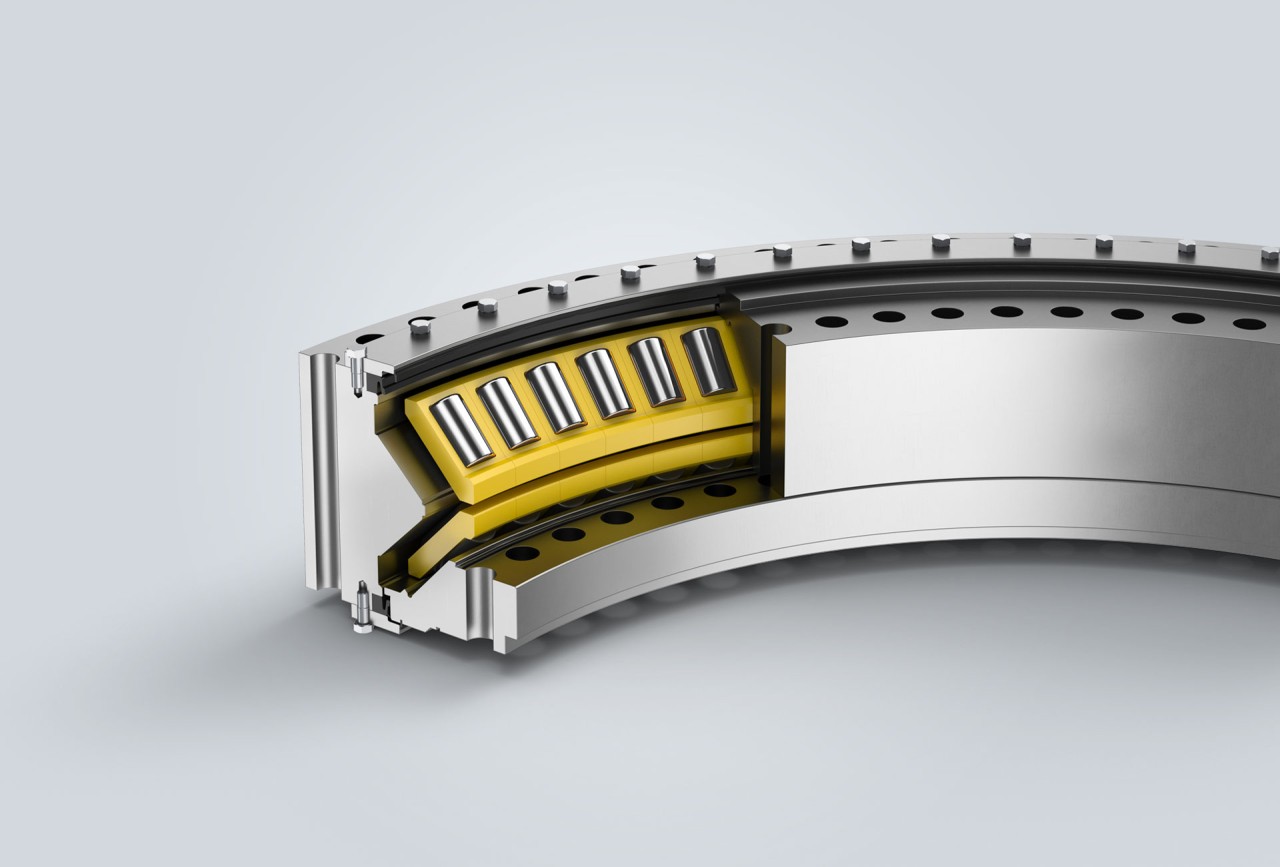

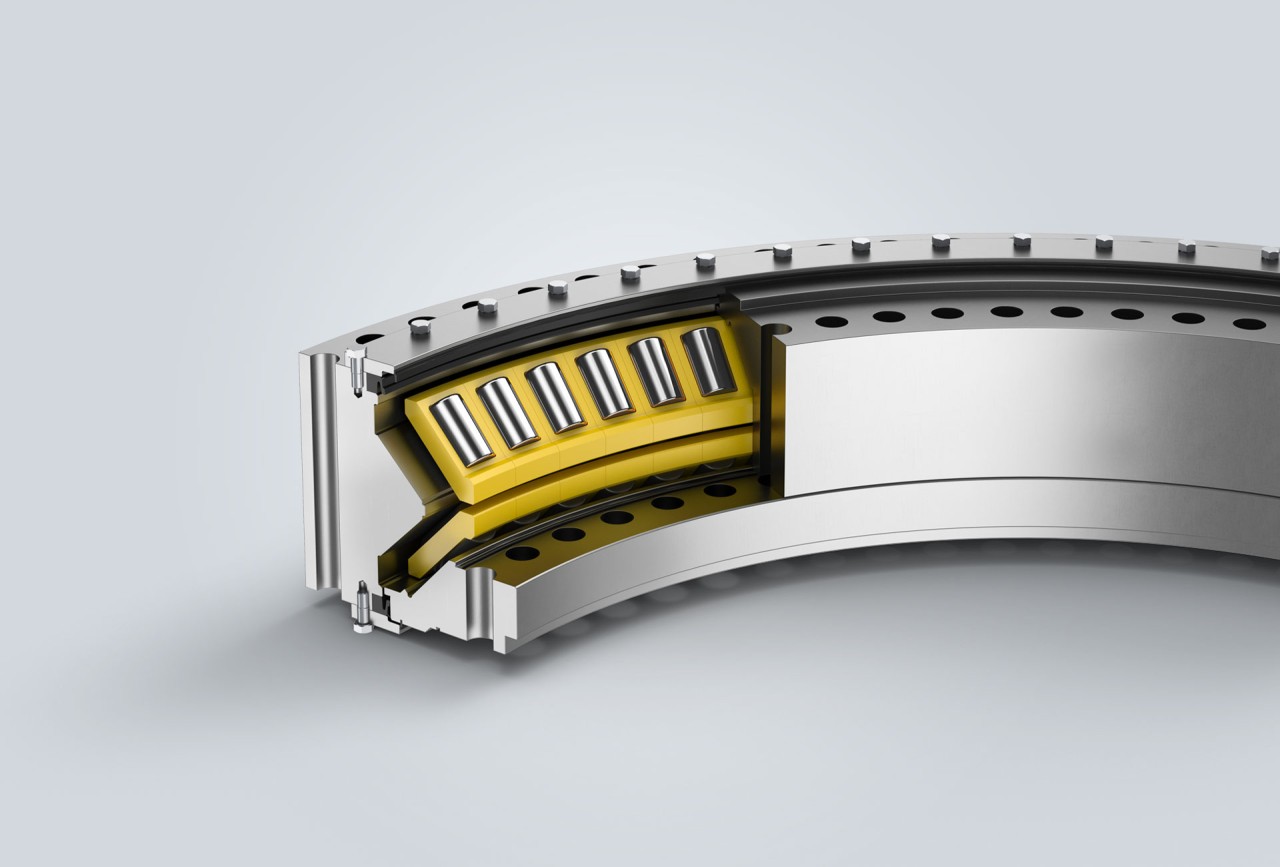

Main bearing

Main bearings are the core of your wind turbine. Enjoy ultimate processing quality and absolute reliability.

Depending on the type of wind turbine, triple-row roller bearings, double-row tapered roller bearings or single-row tapered roller bearings are used as main bearings. While the roller bearing leads to lower stresses in the adjacent construction, the tapered roller bearing is particularly attractive because there is no play, which helps keep functioning of the rolling element optimal. We would be happy to help you the best component.

Product features

Product advantages at a glance:

- robust and long-lasting design

- maximum reliability thanks to precise manufacturing

- safe components through quality testing according to strict industry requirements

- low-wear thanks to slip-free hardened raceways

Operationally reliable. Exchange components from Liebherr.

Innovation combined with decades of experience means high-quality solutions and services for your fleet. With our many years of experience in the wind industry, we can support you with the overhaul or replacement of components to ensure high system availability.

Diagnosis and treatment

Protect the environment and save money: At our certified locations, we offer you the opportunity to restore your slewing bearing to a perfect, functionally-reliable condition at a low cost.

Your advantages:

- increased service life

- reduced maintenance costs

- careful use of resources

- cost-effective alternative to buying new

Maintenance

Liebherr FAT tests: Monitor the condition of your bearings to prevent damage and ensure maximum plant availability.

Liebherr FAT tests:

- Predictive wear and tear measurement prevent

- bearing damage and production downtime

- Rapid, independent analysis and evaluation of your samples

- Efficient planning of repairs, oil changes or replacements

Pitch and yaw bearing grease

Bearings for blade adjustment are subject to special loads like partial standstill, small rotations, and changing loads.

To increase bearing lifetime and optimize the prevention of idle marks and false brinelling marks, Liebherr co-developed a specialized grease for pitch and yaw bearings:

Liebherr Duro Wind PBG is a performance leader in key areas – especially in the low temperature range:

- Wear protection

- Low temperature properties

- Vapour phase corrosion protection

- False brinelling (Riffel test)

Cage & edge

Avoid cage damage and edge breakage due to high loads and operational errors.

Take advantage of:

- optimised micro-geometry of your bearing’s raceway form

- long service life of your cages through accurate roundness, hardened materials and state-of-the-art manufacturing methods

- 30% more load-bearing capacity with the same installation space with our ROD blade bearings

Solutions for tomorrow. Already today.

We already know tomorrow's requirements, today. With our service offerings, we go beyond the components business and give you the support and flexibility you need to be competitive in the market.

Our mission - to ensure the availability and smooth operation of your system

Benefit from our global service offers as well as proven logistics and storage concepts available for immediate use in the event of damage.

Stay flexible

Are you looking to open up new markets quickly and flexibly or expand your production capacity? We can help you achieve it with our Liebherr assembly service, thus releasing you of the need to invest in the capital-intensive construction of your own infrastructure.

Smart Components

Shape the future with us and become a development partner for innovative remote component monitoring systems.

Other topics that may interest you

Locally strong. Globally positioned.

With our worldwide production network, the availability of our components and services is optimal, with guaranteed short delivery times and providing you with local contacts only a stone’s throw away. This decreases transport costs, protects the environment and guarantees top-notch service. Together, we can contribute to low-emission power generation.

Maritime cranes

Mobile and crawler cranes