More about the company

Liebherr careers

Drive solutions for ship and offshore cranes

Our strength is your solution.

A perfectly coordinated interaction of Liebherr components: When combining slewing gearboxes, slewing bearings as well as motors, an optimally adapted system is created that impresses with minimum torsional backlash.

Applications:

- Ship cranes

- Offshore cranes

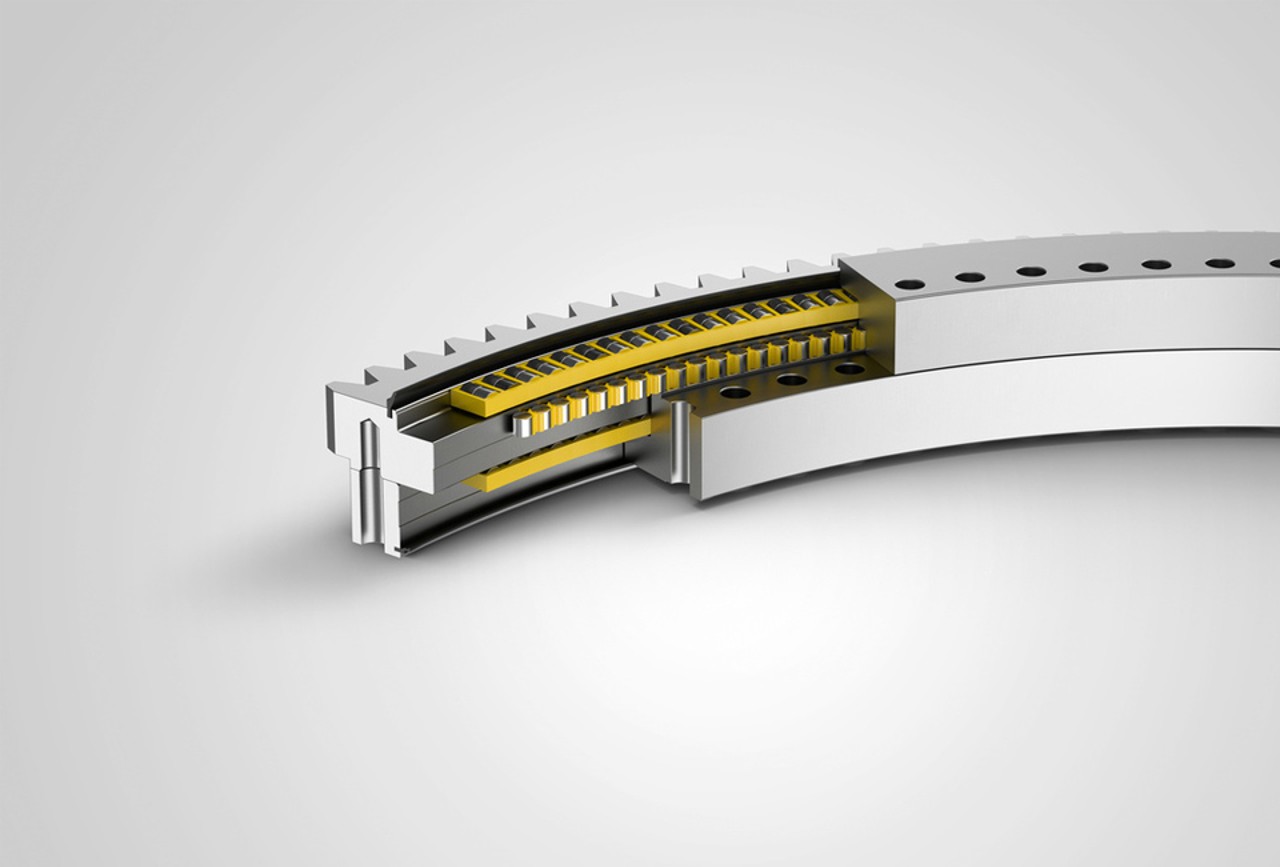

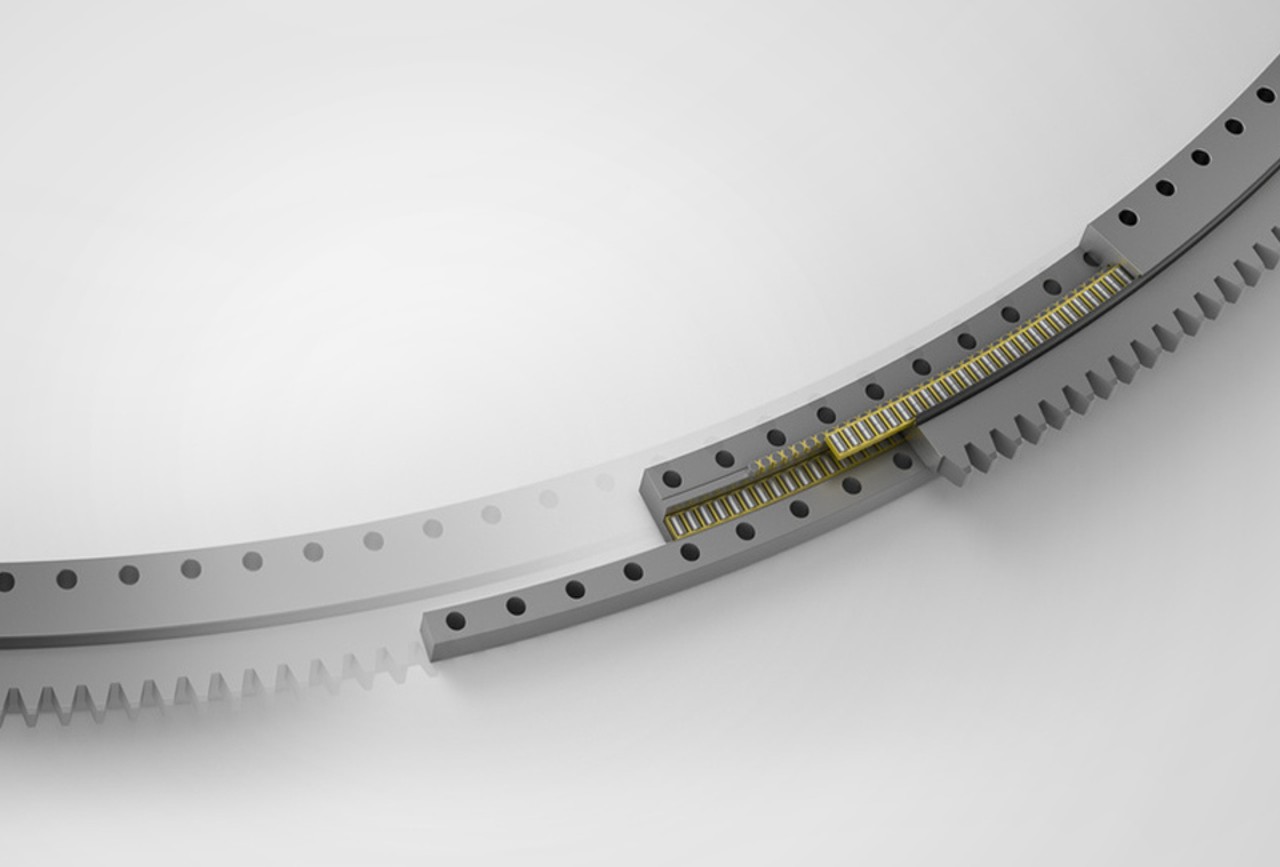

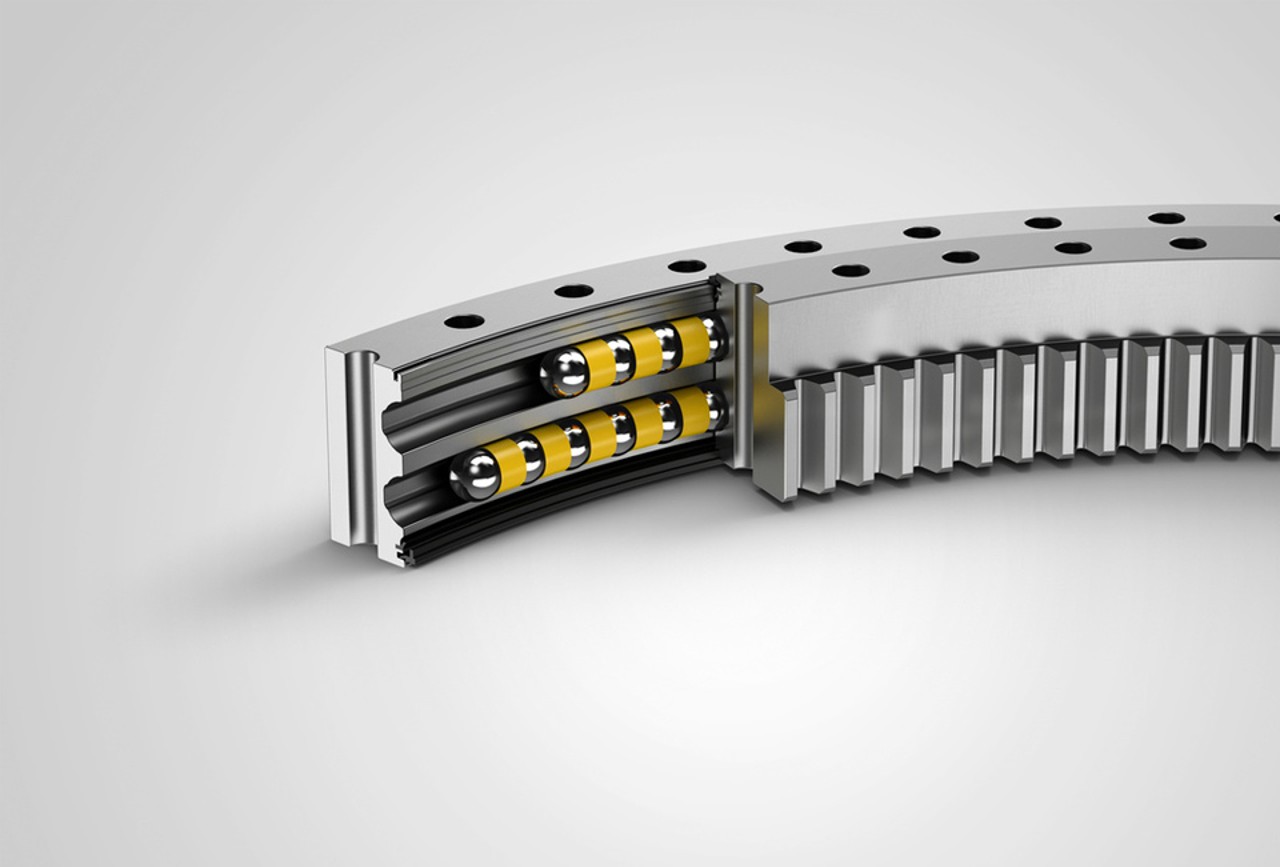

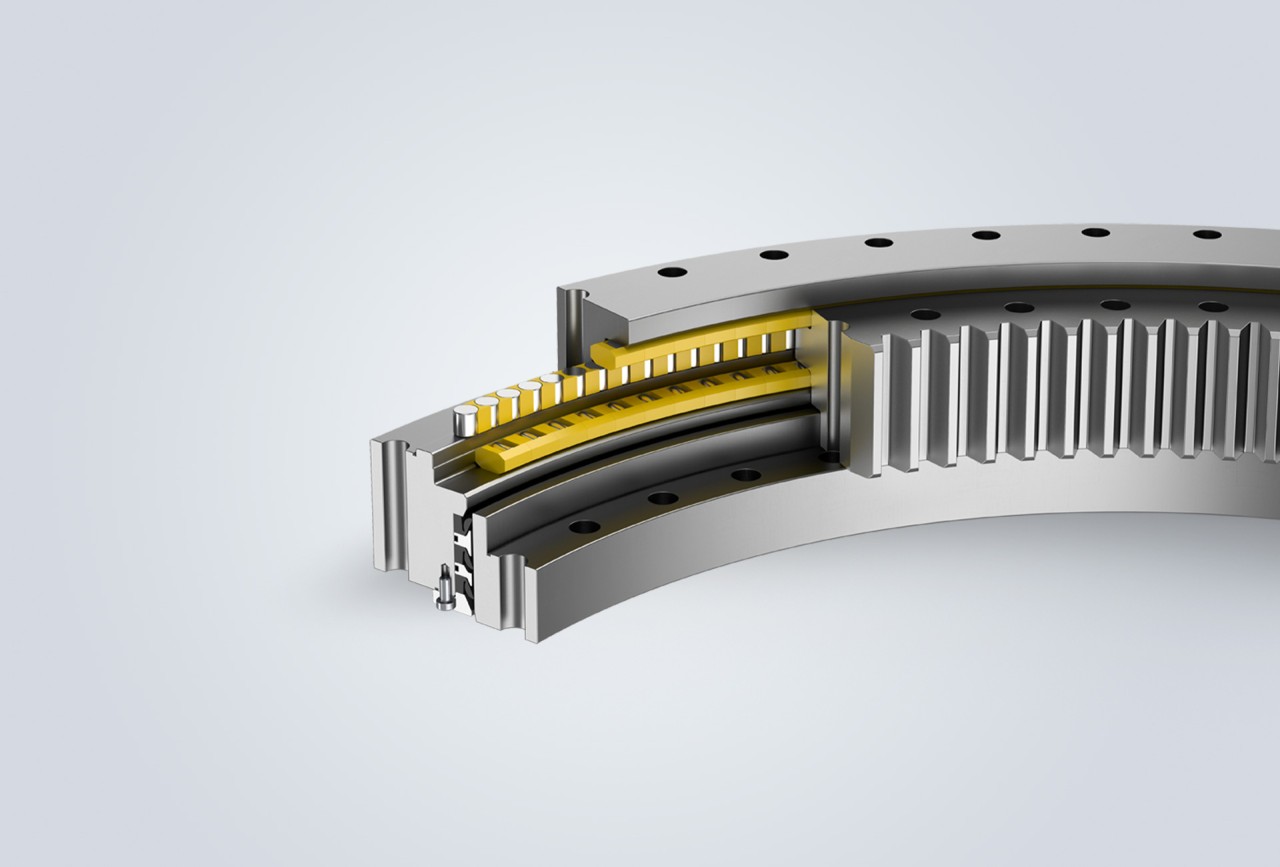

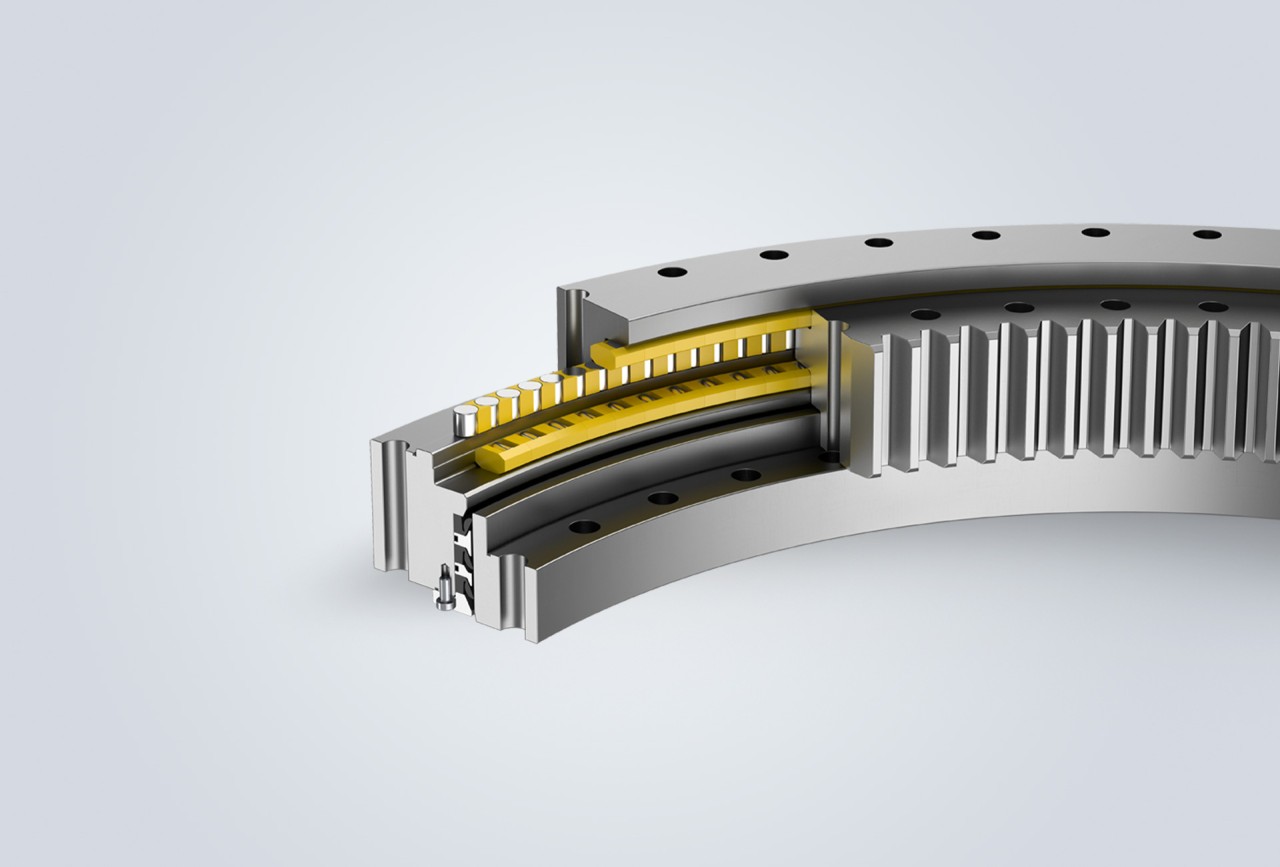

Slewing bearings

Types: Roller / Ball-bearing slewing rings / Segmented large bearings

External diameter: 800 – 9,500 mm, 9.500 mm +

Rolling element diameter: 12 – 140 mm, 140 mm +

Gearing: External / Internal / Customized / No gearing

Advantages:

- Extremly durable

- Made for harsh environmental conditions?

- Best-in-class customer response times

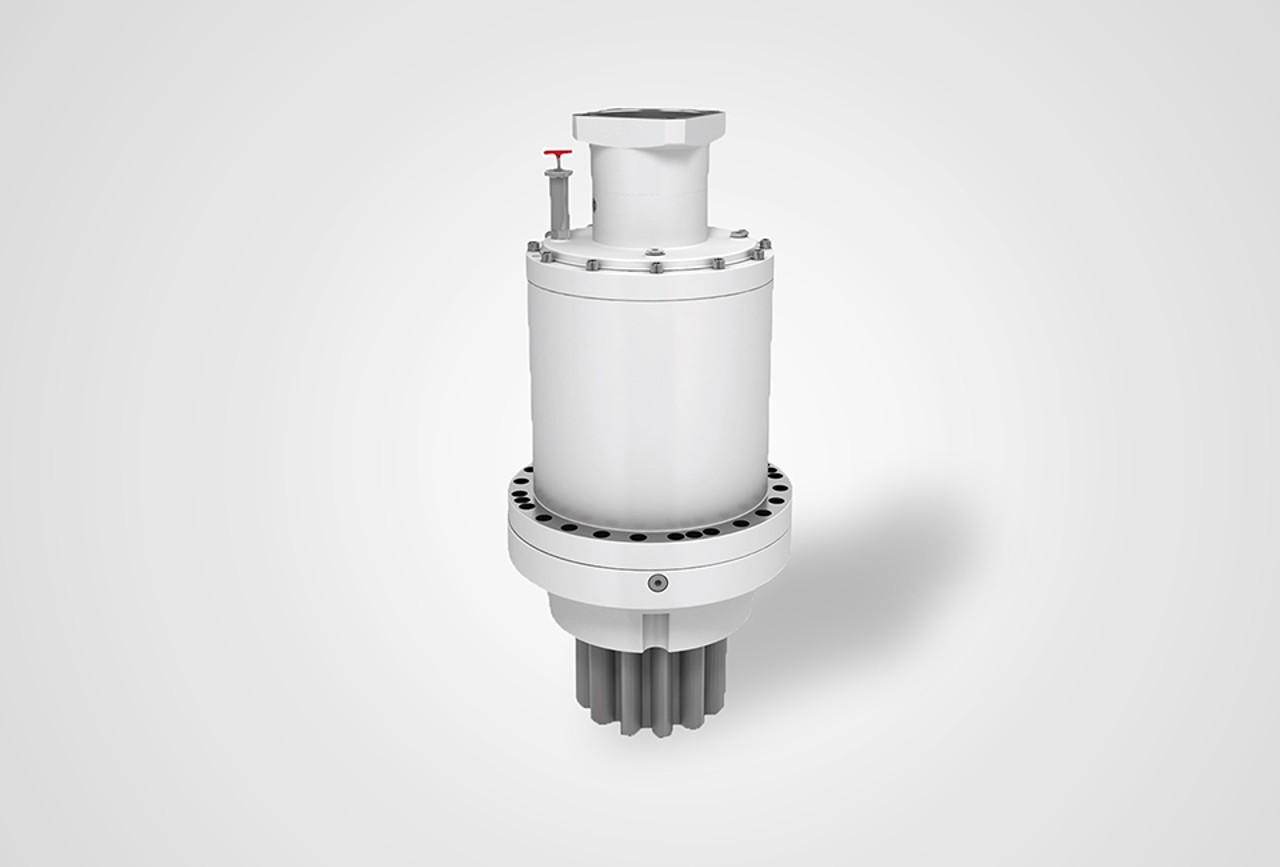

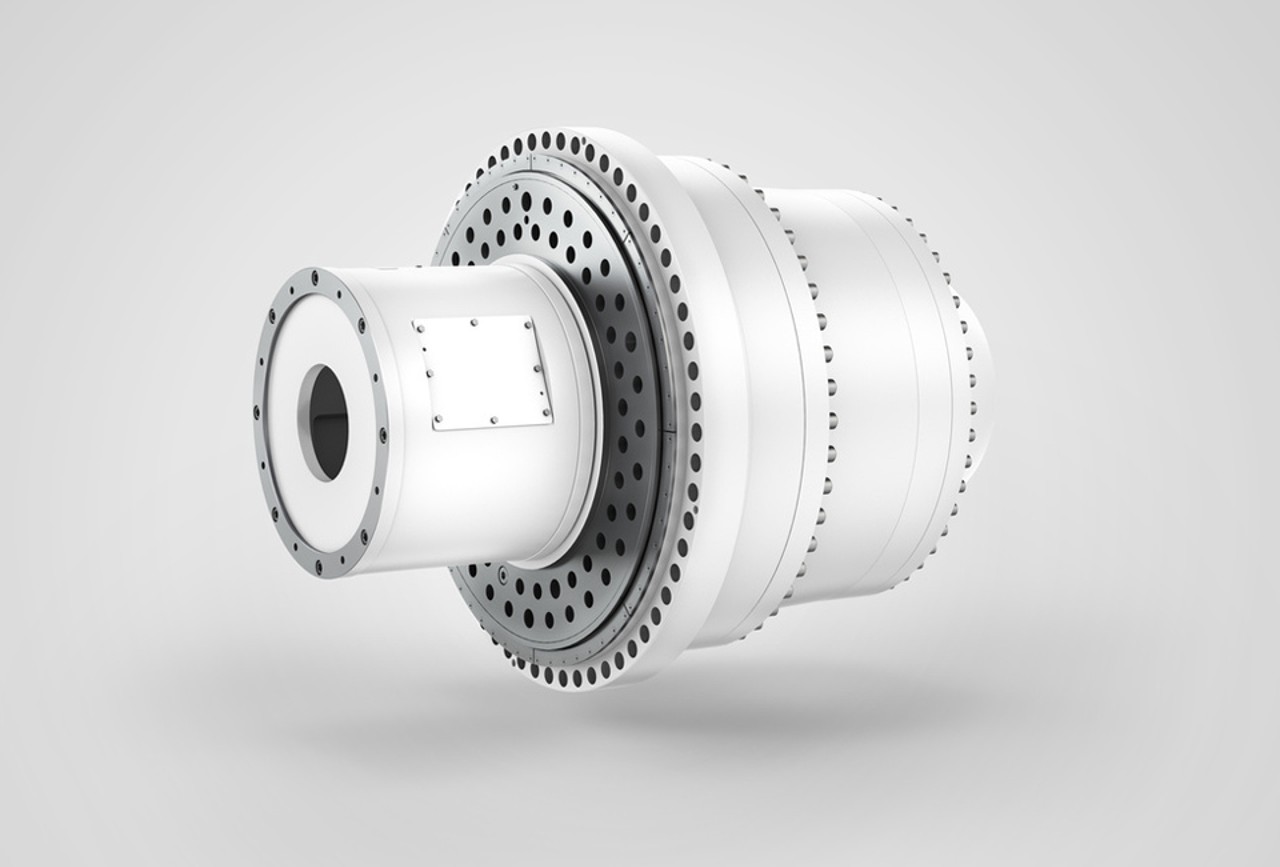

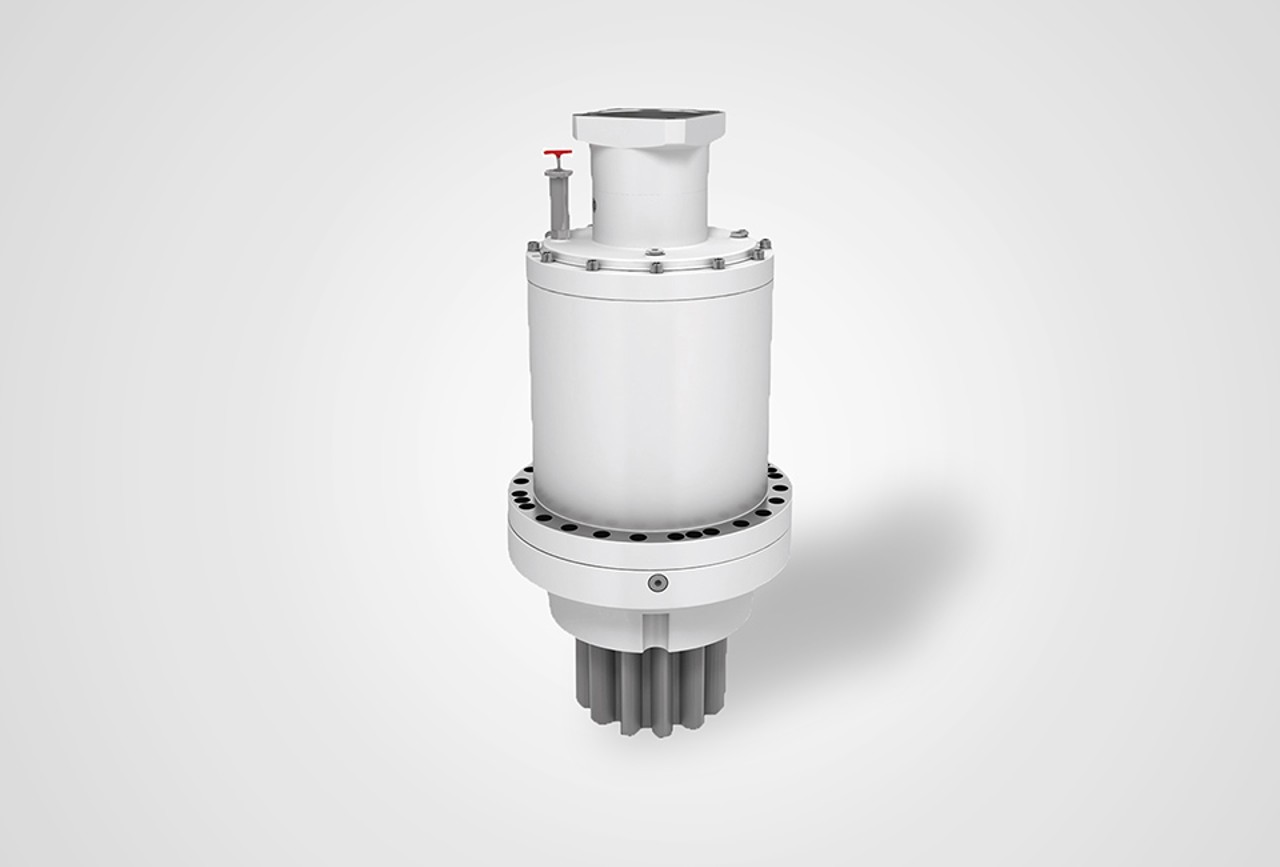

Planetary gearboxes

Type: LPI 600 – LPI 1200 / PEG 800 – PEG 1200

Output torque: 27,500 – 1,250,000 Nm

Collective: L2 / T5 / M5

Advantages:

- Maximum torque density

- Lightweight

- Reduced installation space

- Optimised combination of efficiency and reliability

- Easy to maintain

- Prepared for condition monitoring

- Hydraulically or electrically driven

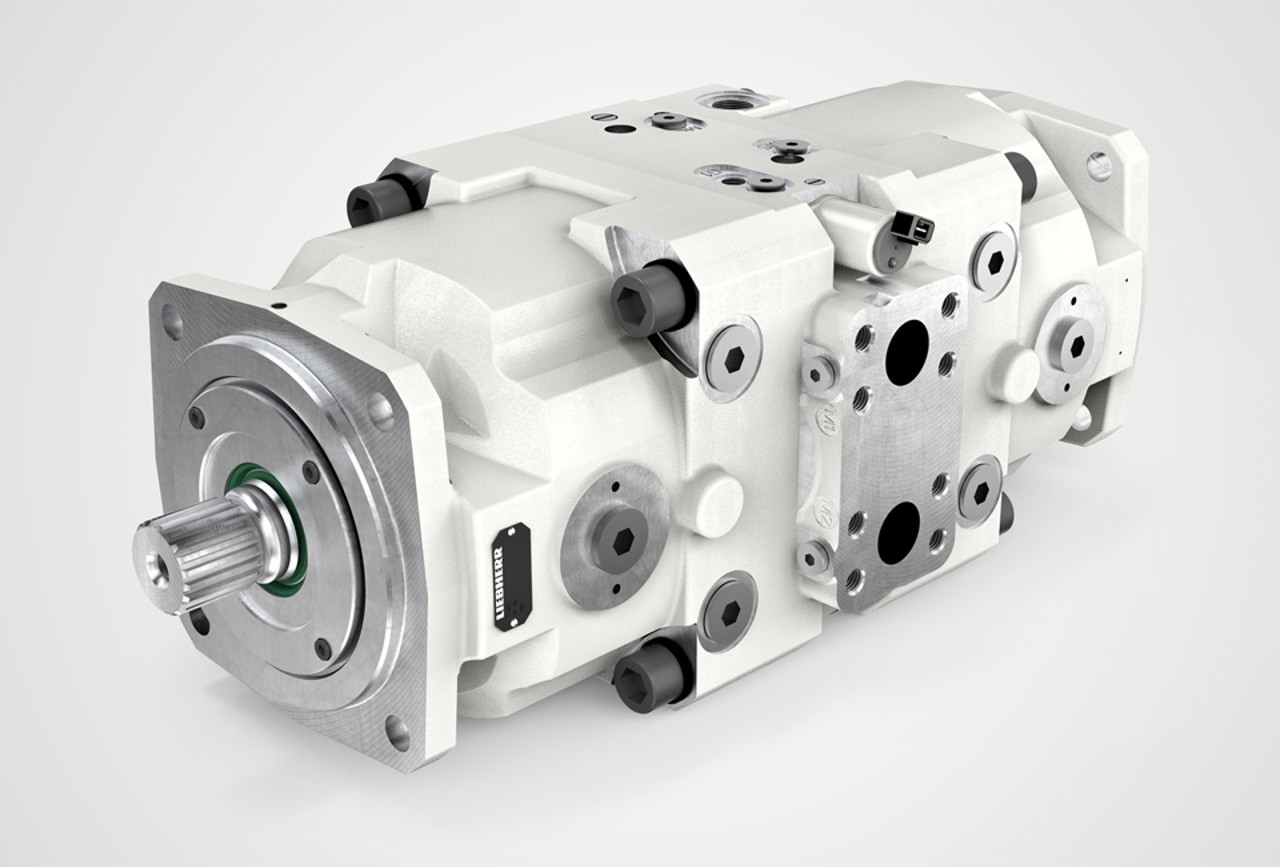

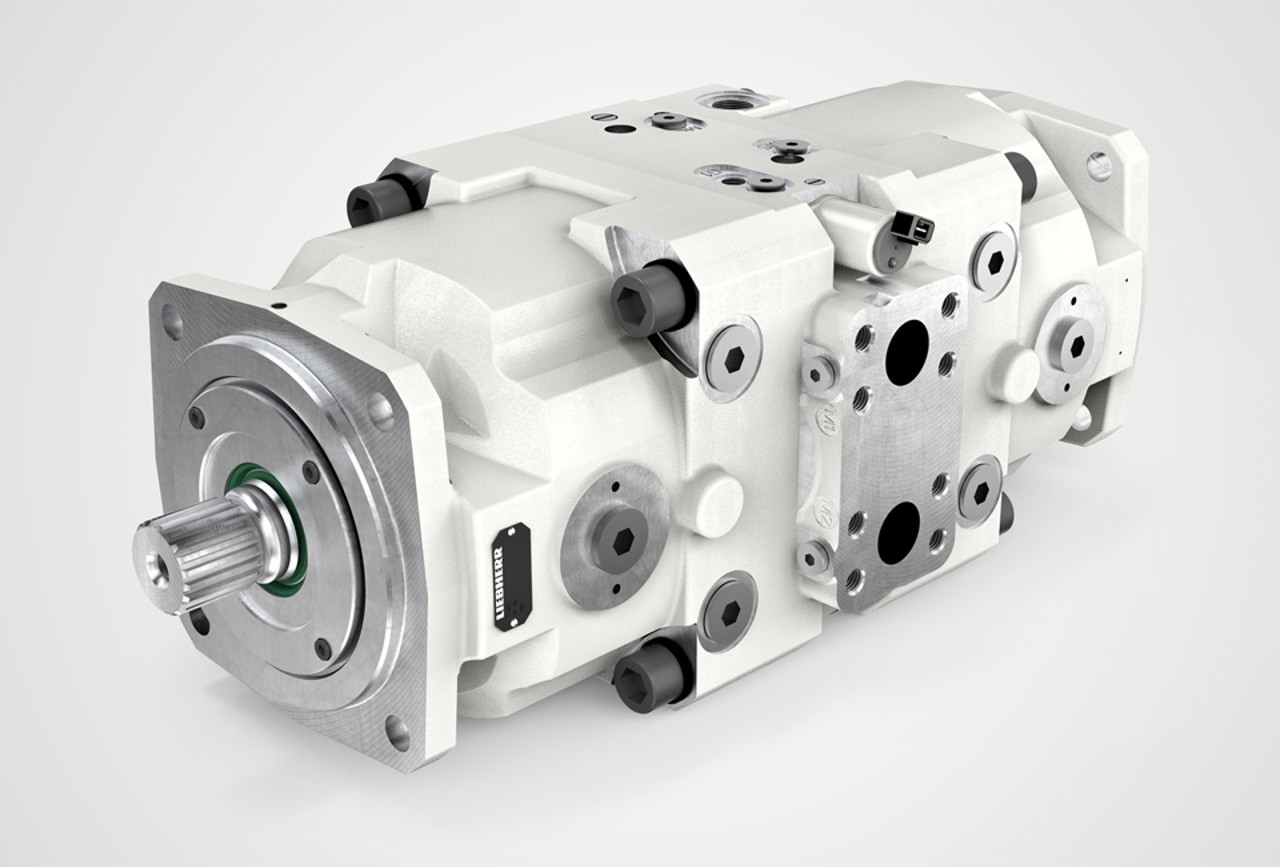

Axial piston double motor

Circulation: Closed / Open

Adjustability: Variable

Nominal pressure: 450 bar

Maximum pressure: 500 bar

Nominal sizes: 165 – 108, 165 – 165, 165 – 215, 215 – 165

Advantages:

- Extremely robust and reliable

- High efficiency and power density

- Rotary groups are separately or parallelly adjustable

- Common port plate simplifies piping installation

- Also available as a single unit axial piston motor

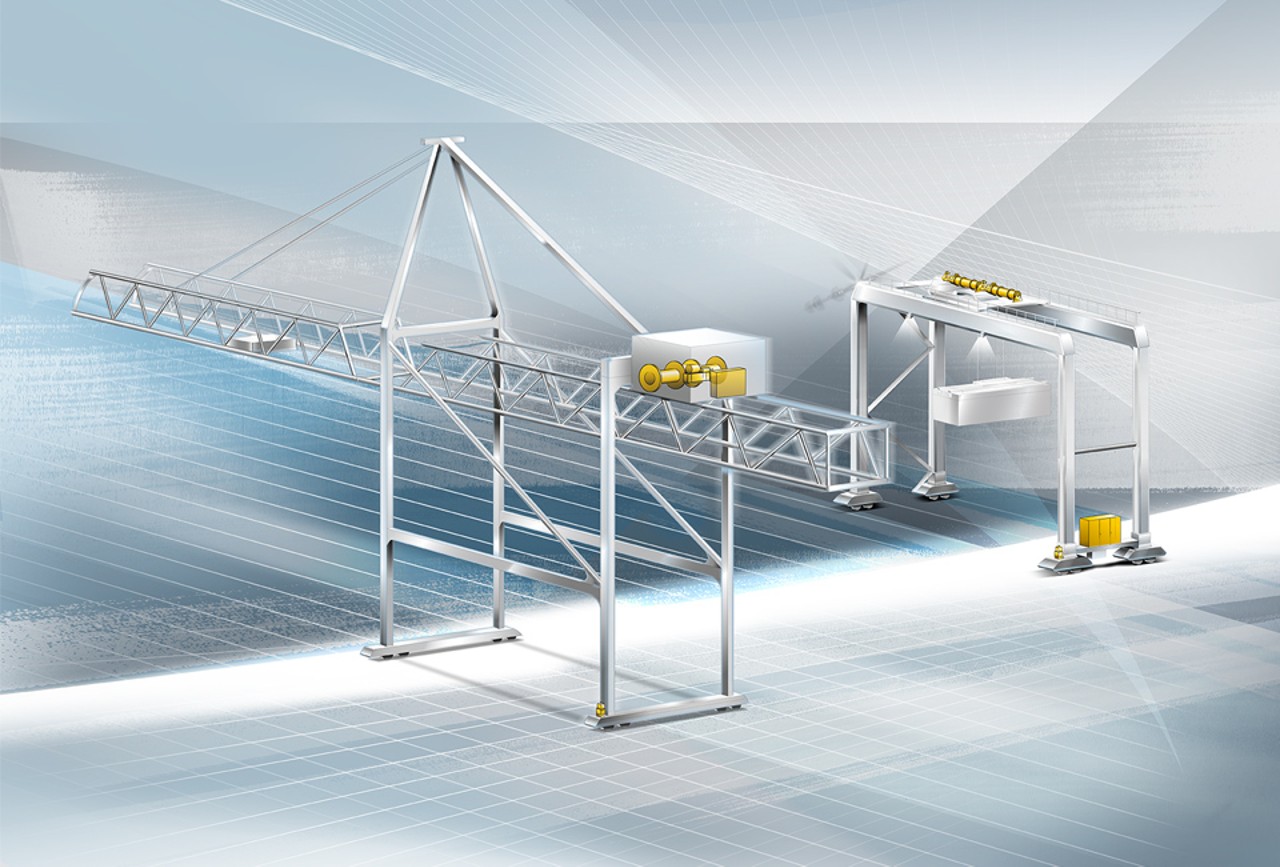

Drive systems for port cranes

Designed for extreme conditions and demands

Liebherr components impress as reliable solutions in harbour areas. Having many years of experience in the maritime arena, we understand the specific requirements of the industry and the different applications:

Rubber-tired gantry cranes

Rail-mounted gantry cranes

Ship-to-shore cranes

Specialized port cranes

Mobile harbour cranes

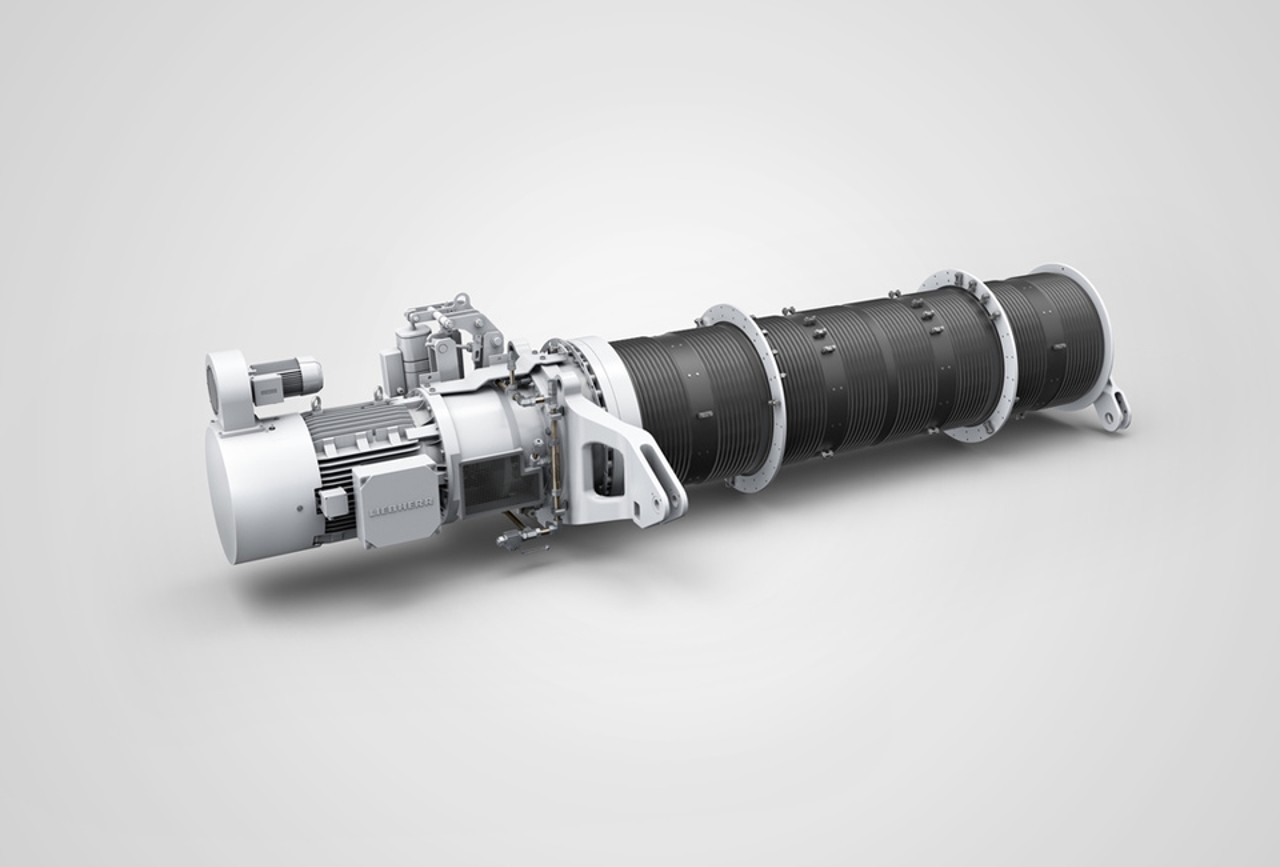

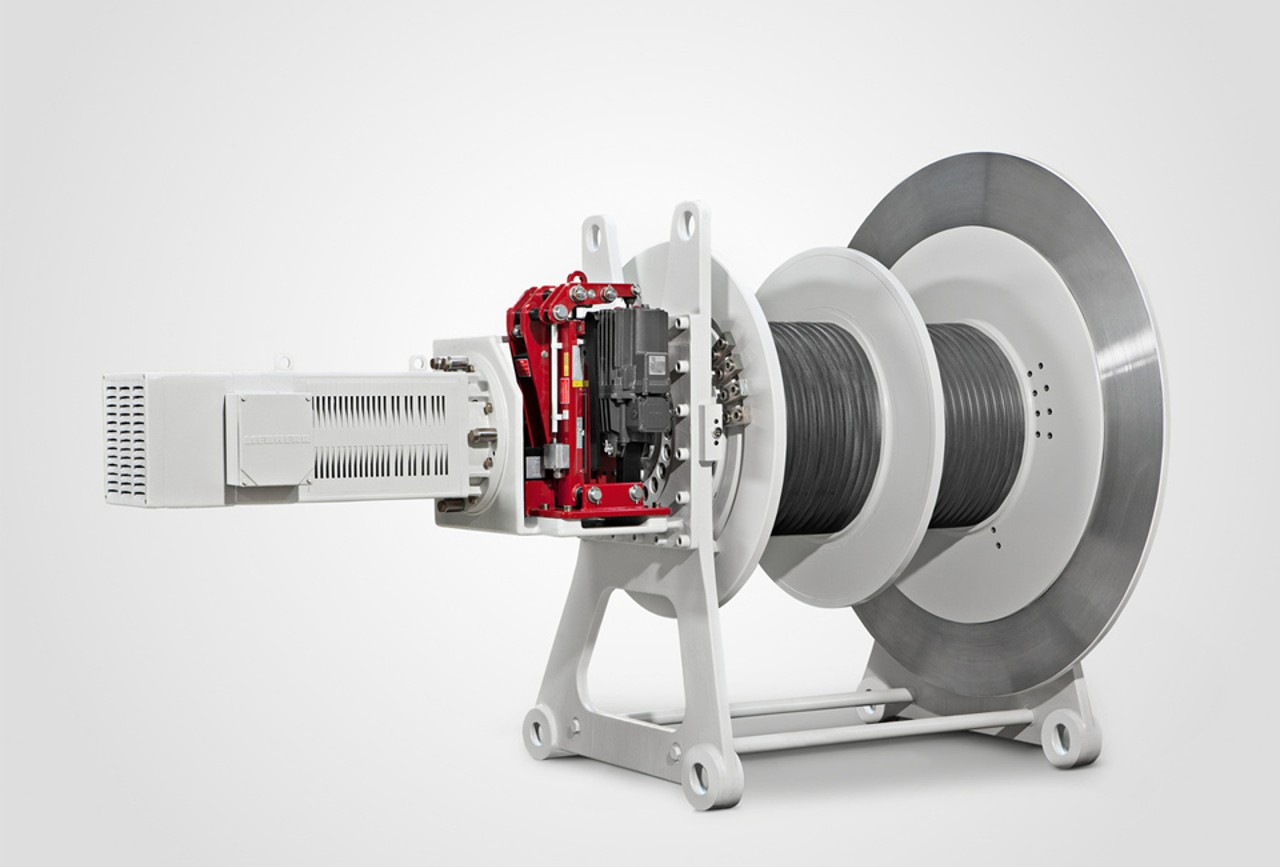

Container hoisting winch

Compact, light, reliable: Liebherr supplies a wide range of winch systems including the container hoisting winch which is particularly used for rubber-tired gantry cranes as well as rail-mounted gantry cranes. By using plug-in gearboxes, you will benefit from a more compact and lighter container hoisting winch.

Type: CHW 800

Rope diameter: 26 mm

Drum diameter: 810 mm

Drive: Hydraulic and electric motor

Weight: 6,000 – 7,000 kg

Compact / Heavy-duty rope winches

Perfect safety: Liebherr compact and heavy-duty rope winches impress with a compact design, optimised drums and reliable operation.

Type: KSW 400 – 1000 / SSW 450 – 1100

Rope diameter: 20 – 52 / 26 – 54 mm

Drum diameter: 490 – 1,240 / 550 – 1,200 mm

Drive: Hydraulic and electric motor

Weight: 715 – 12,000 / 2,000 – 11,000 kg

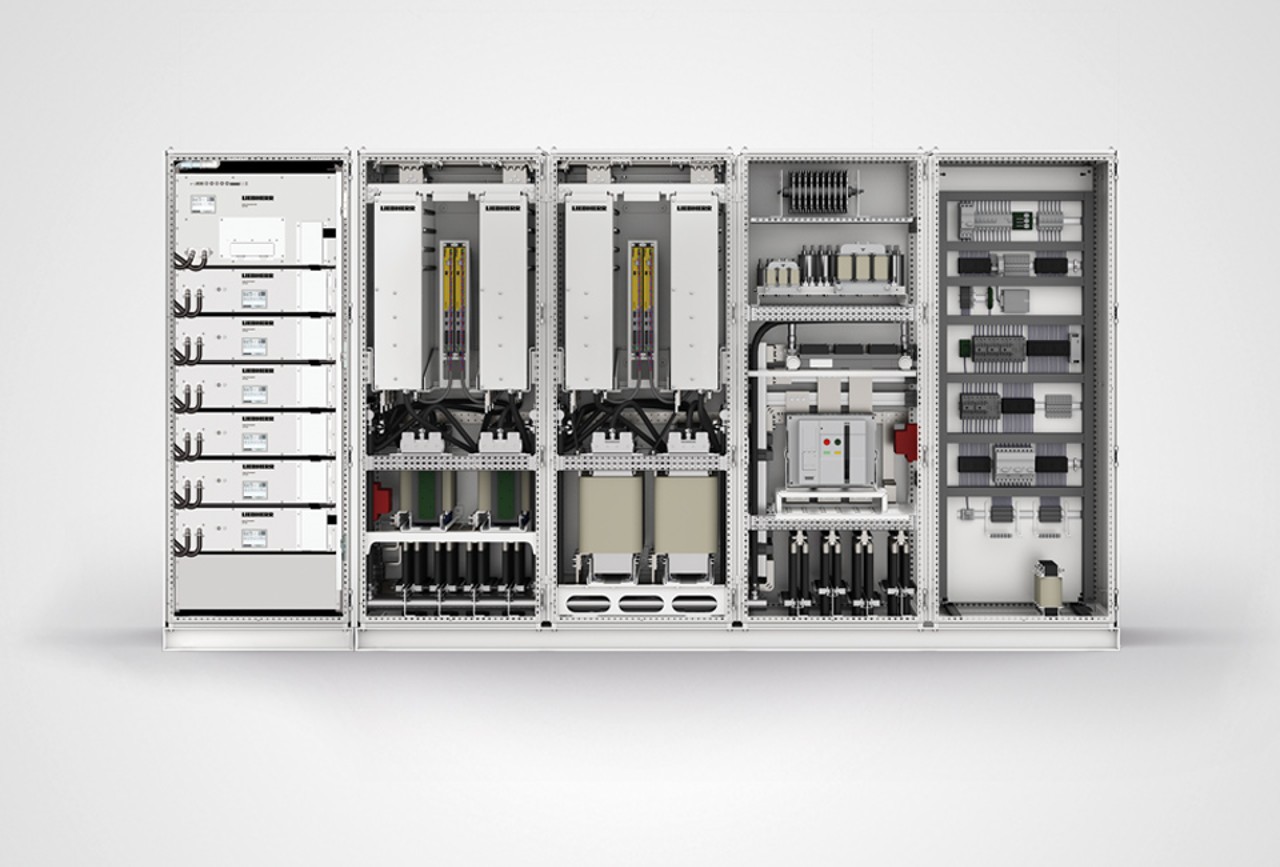

Liduro Energy Storage

Peak load shaving with ultracapacitors: Through the storage and efficient use of recuperative energy the dimensioning and total cost of crane operations can be reduced by 20 – 40%.

Applications can be downsized on various levels: Gensets, cable cross-sections, connection points, and overall energy consumption.

Storage medium: Double-layer capacitors

Energy content: 690 – 4,140 kJ

Power output: up to 100 kW / up to 200 kW

Liduro drive system

Efficiency and operational safety: Liebherr converters for electric drive systems are distinguished by their high power density and protection level. The components of the liquid-cooled systems are low2no maintenance products and are designed for reliable operation in extreme ambient conditions.

Integrated energy storage: The Liduro Energy Storage LES 300 can be added and integrated into the system LCM 300.

Liduro Converter Drive – LCM 300

Power ranges: 110 – 4,000 kW

Voltage range: 380 / 500 / 690 V

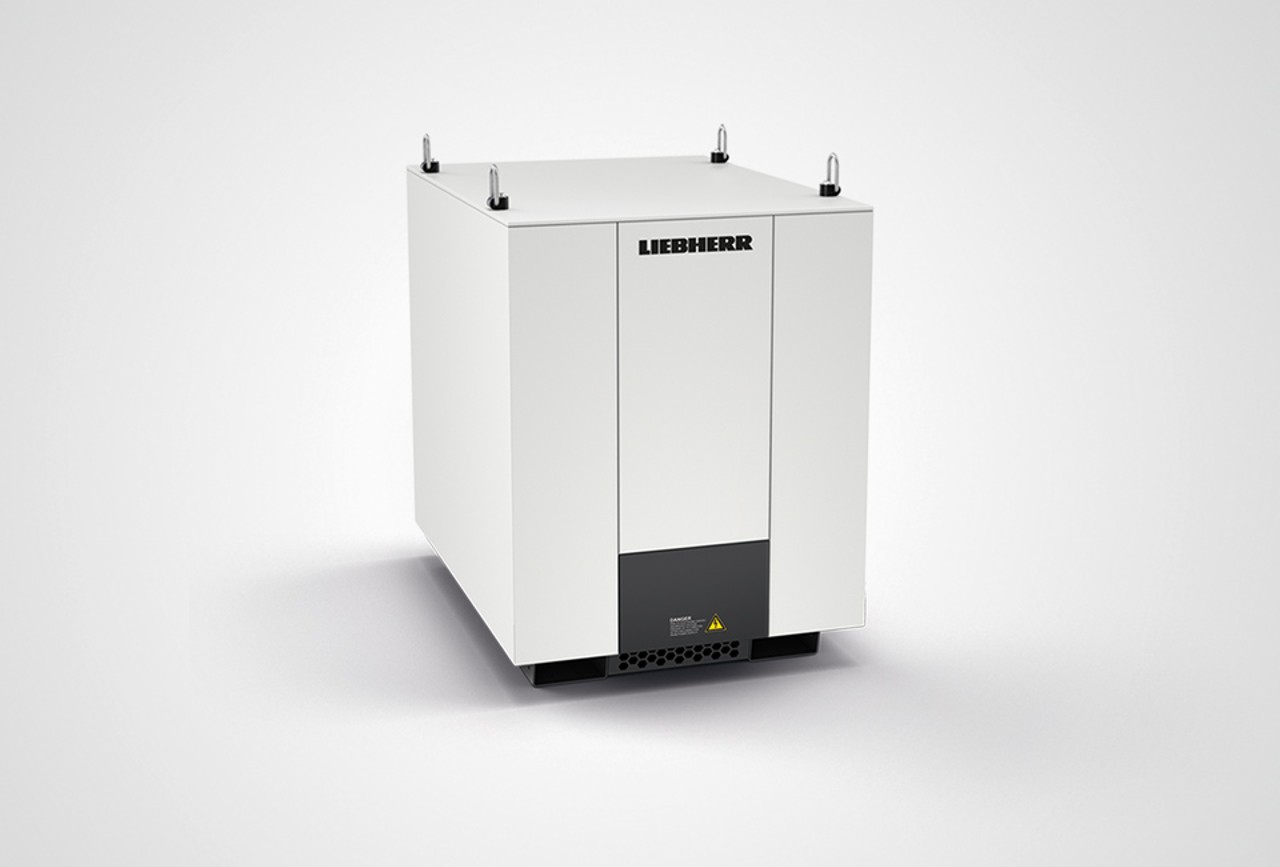

Liduro Energy Storage

Solution for mobile applications: The LES 200 has a well thought-out protection concept: In the event of a fault, an isolating unit with fuses and switching contacts separates the storage from the power supply.

Ultracapacitors / Liquid-cooled

Energy content: 1,500 kJ

Power output: up to100 kW

Dimension (W / D / H): 750 / 1,120 / 1,100 mm

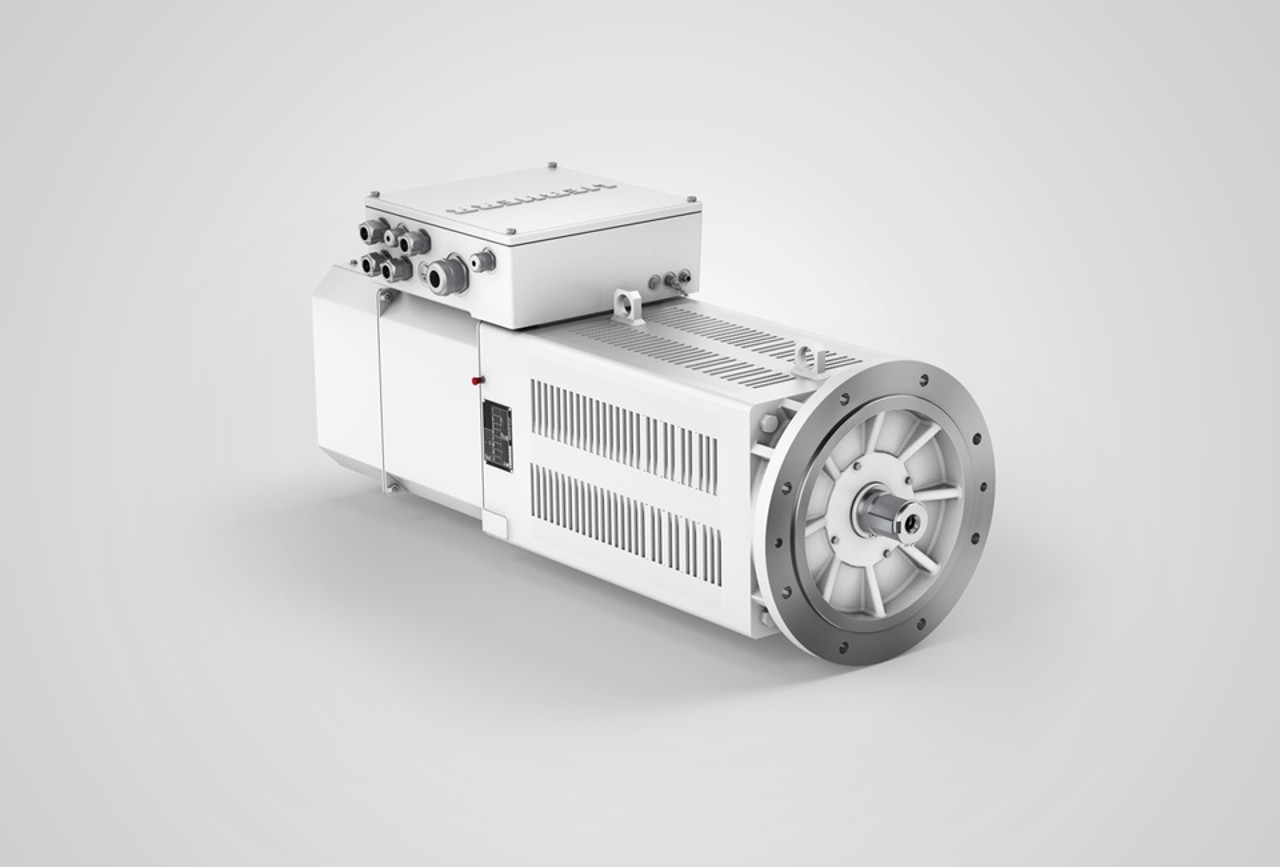

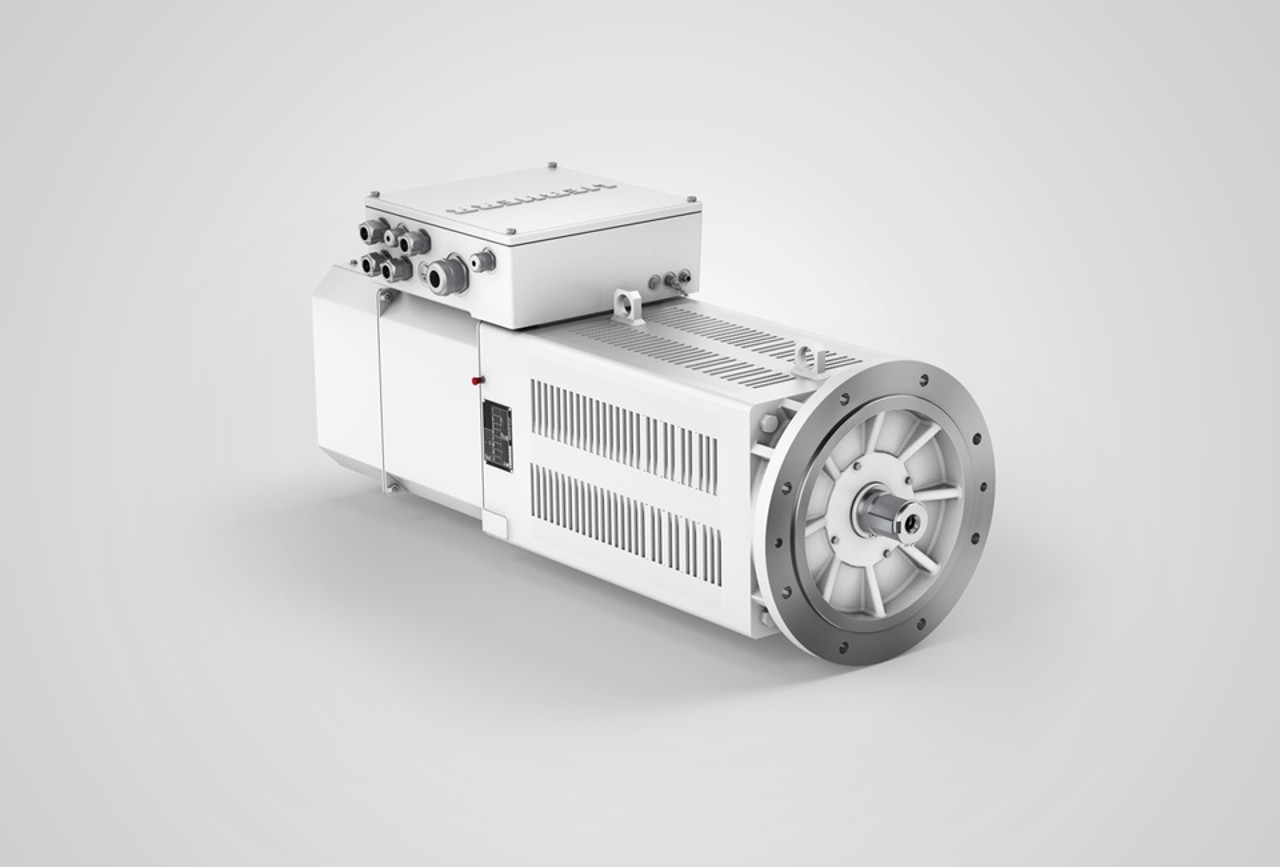

Licore Asynchronous Motors

Slewing gearboxes

Maximum quality and reliability: Liebherr gearboxes as part of a complete system solution together with large diameter bearings and electric motors.

With over 60 years of experience in designing and manufacturing slewing gearboxes, high quality and performance is always in focus.

Types: DAT 250 – 450

Output torque: 11,000 – 60,000 Nm

Slewing bearings

Extremely durable, made for harsh environmental conditions

Types: Roller / Ball-bearing slewing rings / Segmented large bearings?External diameter: 800 – 9,500 mm, 9.500 mm +

External diameter: 800 – 9,500 mm, 9.500 mm +

Rolling element diameter : 12 – 140 mm, 140 mm +

Gearing: External / Internal / Customized / No gearing

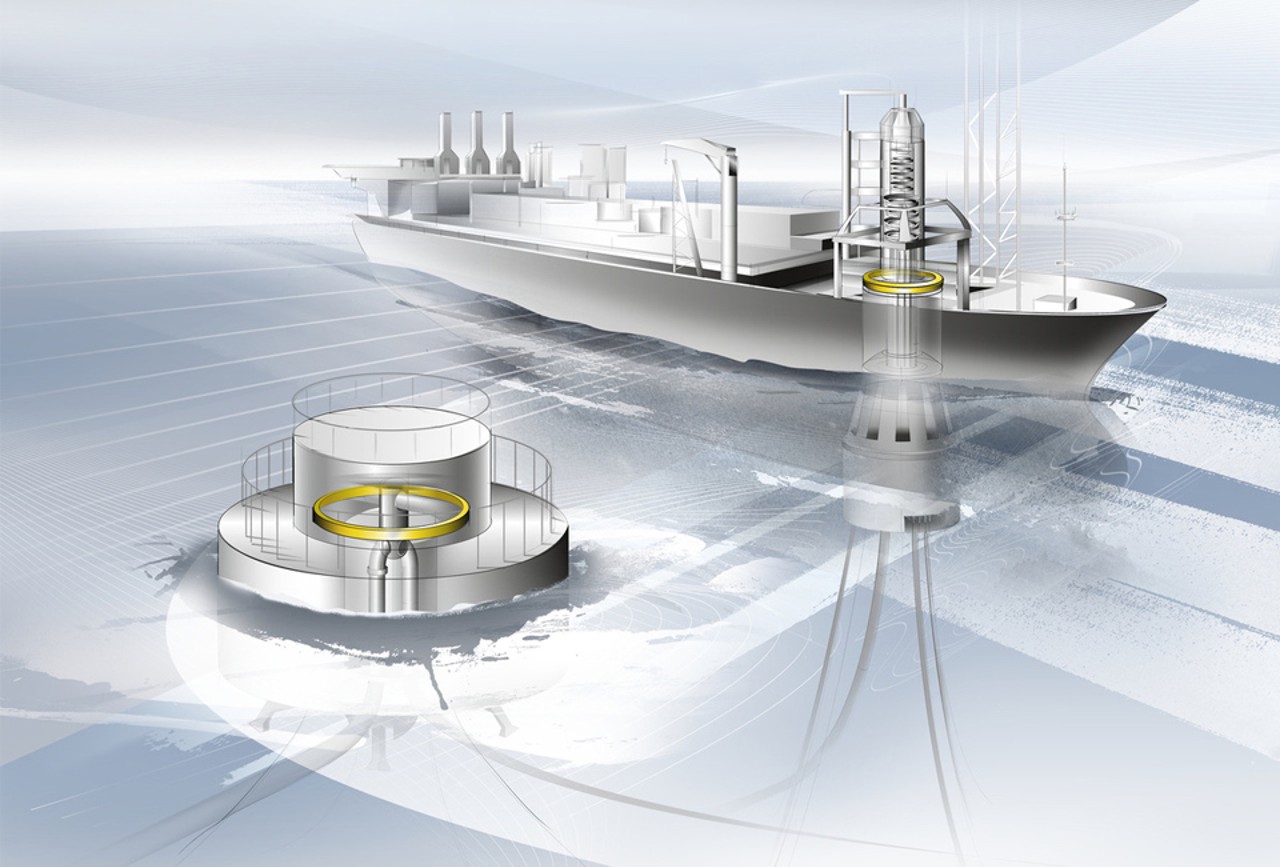

Components for turrets and buoys

Made for harsh environmental conditions: Slewing bearings provided within best-in-class customer response times

Large / Segmented slewing bearings:

Types: Roller / Ball-bearing slewing rings / Segmented large bearings

Protection: Special sealing and / or surface protection

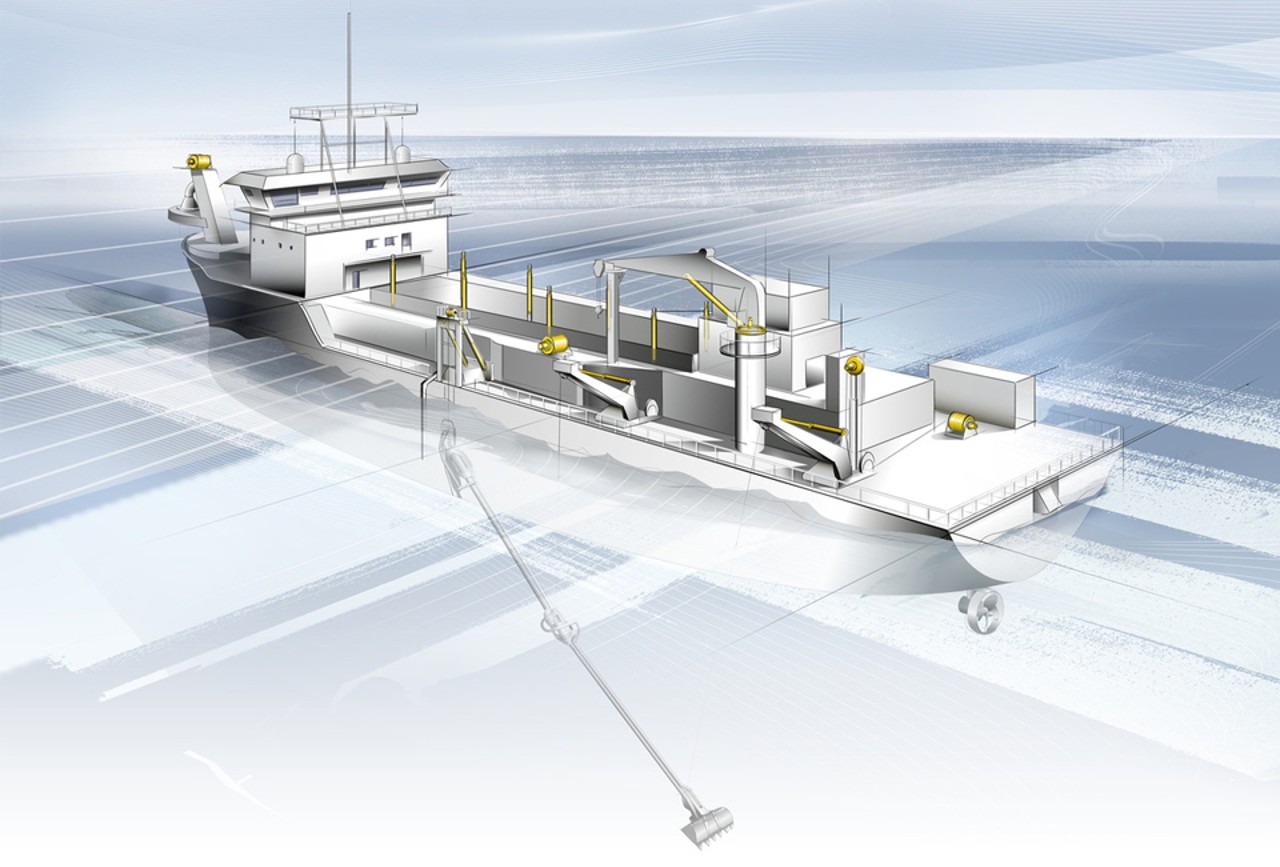

Components for dredging winches

Reliable and powerful: Thanks to their compact design, their ease of use and their long lifetime, the Liebherr gearboxes and hydraulic motors cover a broad range of deployment situations.

Planetary gearboxes

Axial piston double motors

Customer-specific gearbox solutions

Drives that suit you: Versatile drive variants can be created based on the series products from our product portfolio. By focusing on your requirement, Liebherr manufactures special gearboxes as individual drive solutions.*

Type: LPI 600 – LPI 1200 / PEG 800 – 1200

Output torque: 27,500 – 1,250,000 Nm

Collective: L2 / T5 / M5

Highlights at a glance:

- Many years of experience

- Individualized drive solutions

- Robust in harsh environments

- Long lifetime

Axial piston double motor

Circulation: Closed / open

Adjustability: Variable

Nominal pressure: 450 bar

Maximum pressure: 500 bar

Nominal sizes: 165 – 108, 165 – 165, 165 – 215, 215 – 165

Advantages:

- Extremely robust and reliable

- High efficiency and power density

- Rotary groups are separately or parallelly adjustable

- Common port plate simplifies piping installtion

- Also available as a single unit axial piston motor

Technology leader and development partner

As a technology leader and partner with decades of experience in the development of application-specific solutions, we understand the specific requirements of the industry and its applications. Take a look at our components for various applications in the maritime environment:

Drive solutions for ship and offshore cranes

Components for turrets and buoys

Certified

We have been working closely with prestigious certification and inspection authorities and gained required certifications.

Available

High availability during operation, long availability of spare parts and fast obliging service safeguard the performance of the end equipment.

Application-specific solutions

Based on our flexible and scalable product system, we are providing drive systems and components for ports and ships according to customer-specific requirements for a wide range of applications.

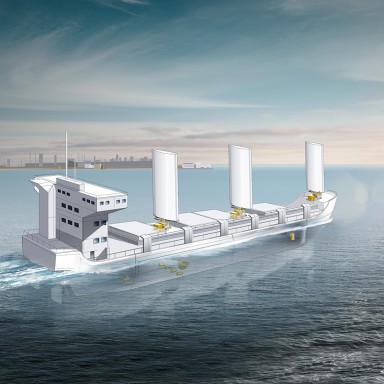

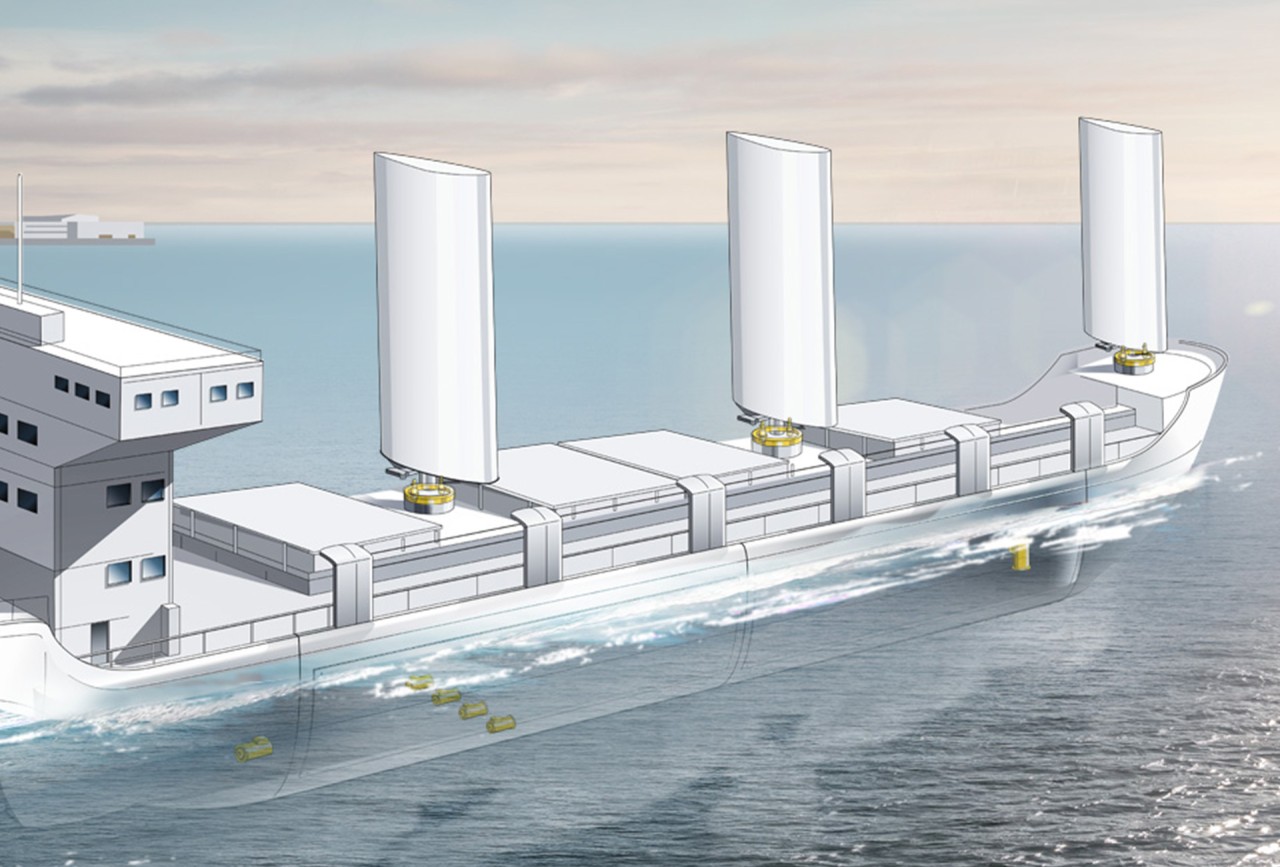

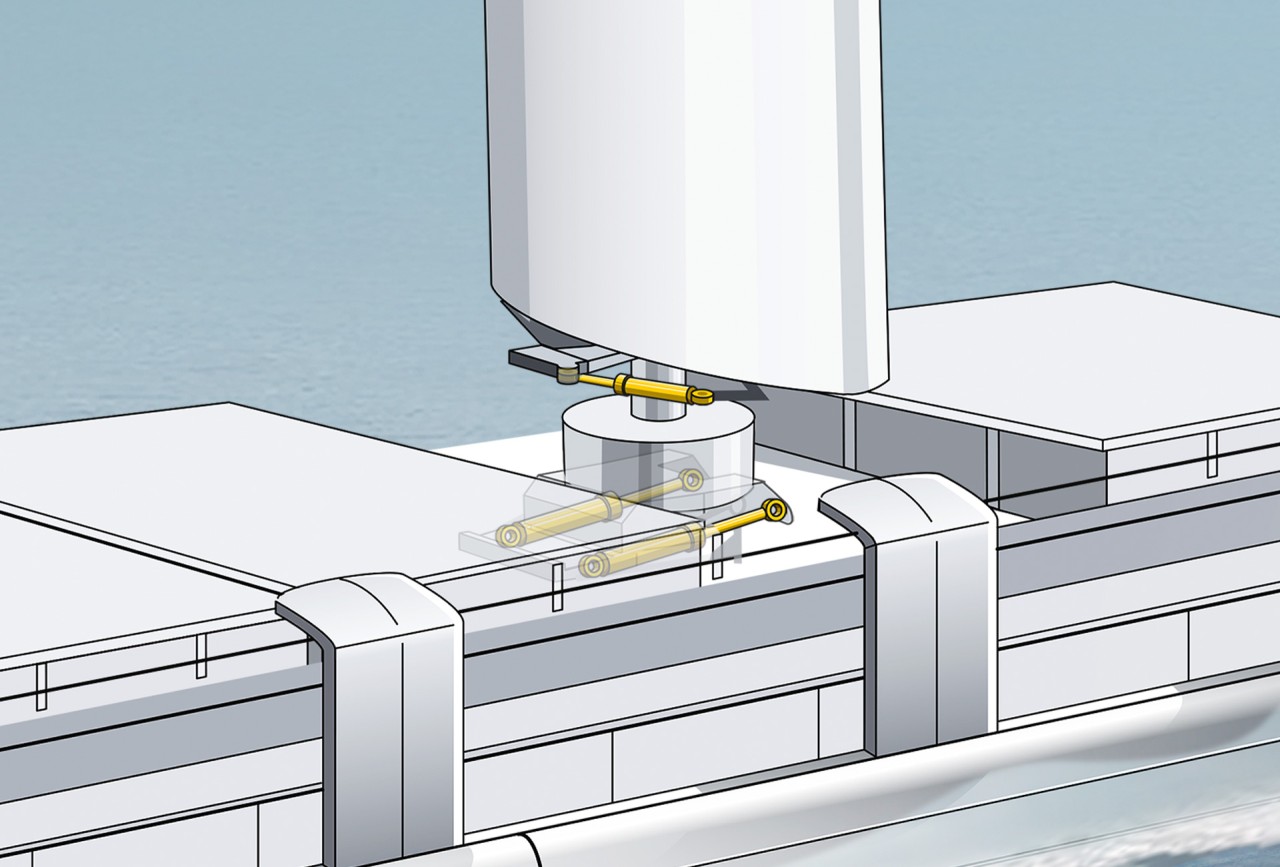

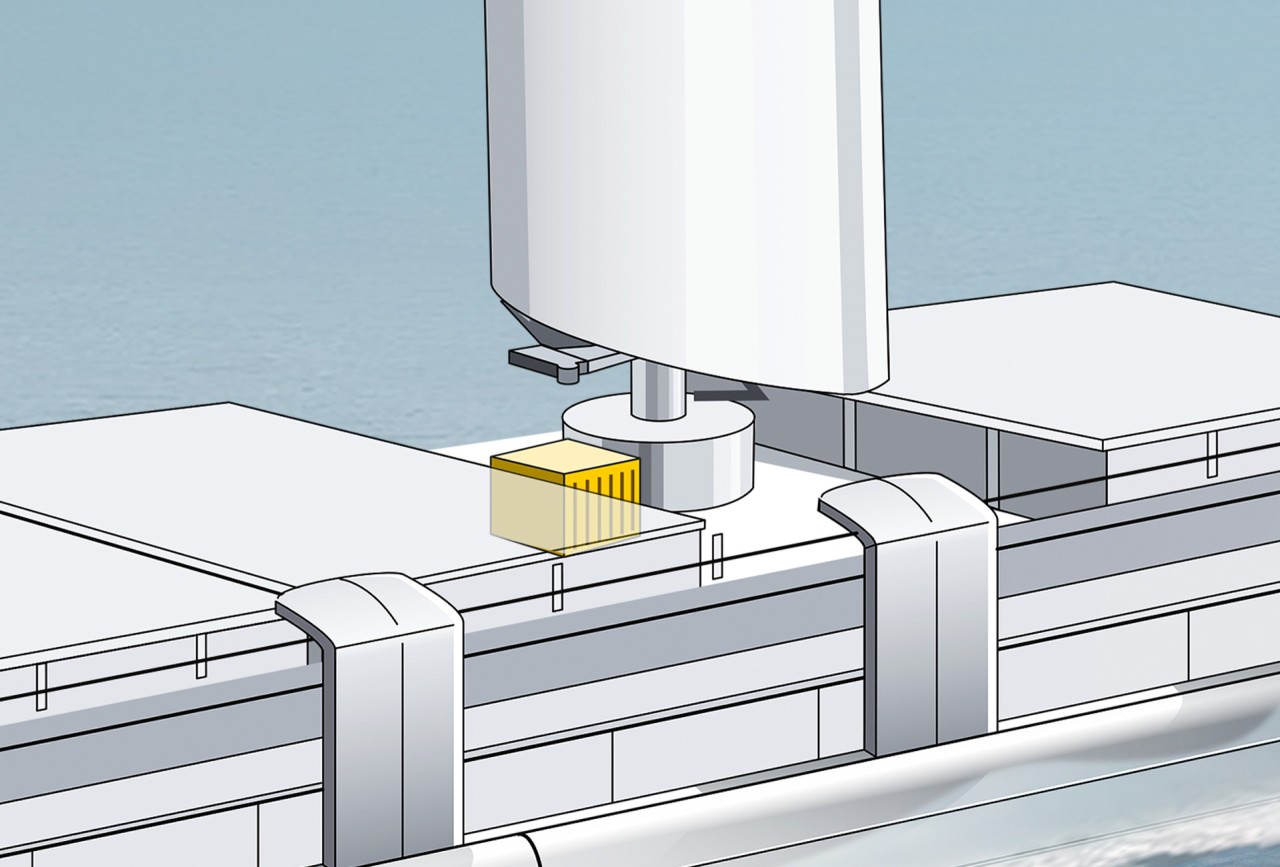

Wind-assisted propulsion

Liebherr offers a complete solution for wind-assisted propulsion, including slewing bearings, drives, and hydraulic cylinders.

Wing sail rotation

Liebherr delivers large-sized slewing bearings and extremely compact and durable slew drives as well as slewing gearboxes for the rotation of wing sails:

Slewing bearings: 800 – 9,500 mm

Slew drives: up to 1,700 mm

Slewing gearboxes: DAT 300 – 450

Sub-systems and components for:

- Flap adjustment

- Various other functions

Slewing bearings

Types: Roller / Ball-bearing slewing rings

External diameter: 800 – 9,500 mm

Rolling element diameter: 12 – 90 mm

Gearing: External / Internal / Customized / No gearing

Advantages:

- Extremly durable

- Made for harsh environmental conditions

- Special forms of seals

Slew drives

Types: Worm gear / Spur gear slew drives

External diameter: up to 1,700 mm

Gearing: External / Internal / Customized / No gearing

Advantages:

- Optimized balance between load capacity and torque

- Extremly durable

- Made for harsh environmental conditions

- Plug and play

Slewing gearboxes

Type: DAT 300 – 450

Output torque: 18,000 Nm – 60,000 Nm

Gear transmission ratio: 1:29 – 1:250

Advantages:

- Over 60 years of experience

- Outstanding quality

- Reliability

- Low installation space required

- High power density

Sub-systems and components

Multiple options for your application: We use our many years of experience and know-how from wind, mobile or maritime applications to develop customized drive systems and solutions for various applications:

- Flap adjustment

- Mast tilting

- Mast telescoping

- Others

Components:

Setting the mast and adjusting the sail

Liebherr supplies offshore-certified, corrosion-resistant and heavy-duty hydraulic cylinders to raise and lower the sail mast and unfold and fold the two-piece wing sails.

Advantages of hydraulic cylinders:

- DNV GL classification

- Two-layer, high-density coating for excellent corrosion resistance, optimum sealing properties and maximum seal life

- Flexible position measurement system

- Pressure sensors and load holding valves

- Cylinder emergency release valve

- Leakage-free counterbalance valve

- Reliable shut-off and pipe break protection

Folding cylinder

Folding cylinders are used to fold and unfold the sail surfaces. The folding of the sails is assisted by the wind by aligning the sails accordingly.

Operating pressure: 250 bar

Test pressure: 375 bar

Piston diameter: 380 mm

Length of hydraulic cylinder retracted: 4080 mm

Length of hydraulic cylinder extended: 6940 mm

Stroke: 2860 mm

Tilting cylinder

Tilting cylinders are used to raise and lower the sails. The wind assists in lowering the sails.

Operating pressure: 250 bar

Test pressure: 375 bar

Piston diameter: 440 mm

Length of hydraulic cylinder retracted: 5180 mm

Length of hydraulic cylinder extended: 9020 mm

Stroke: 3840 mm

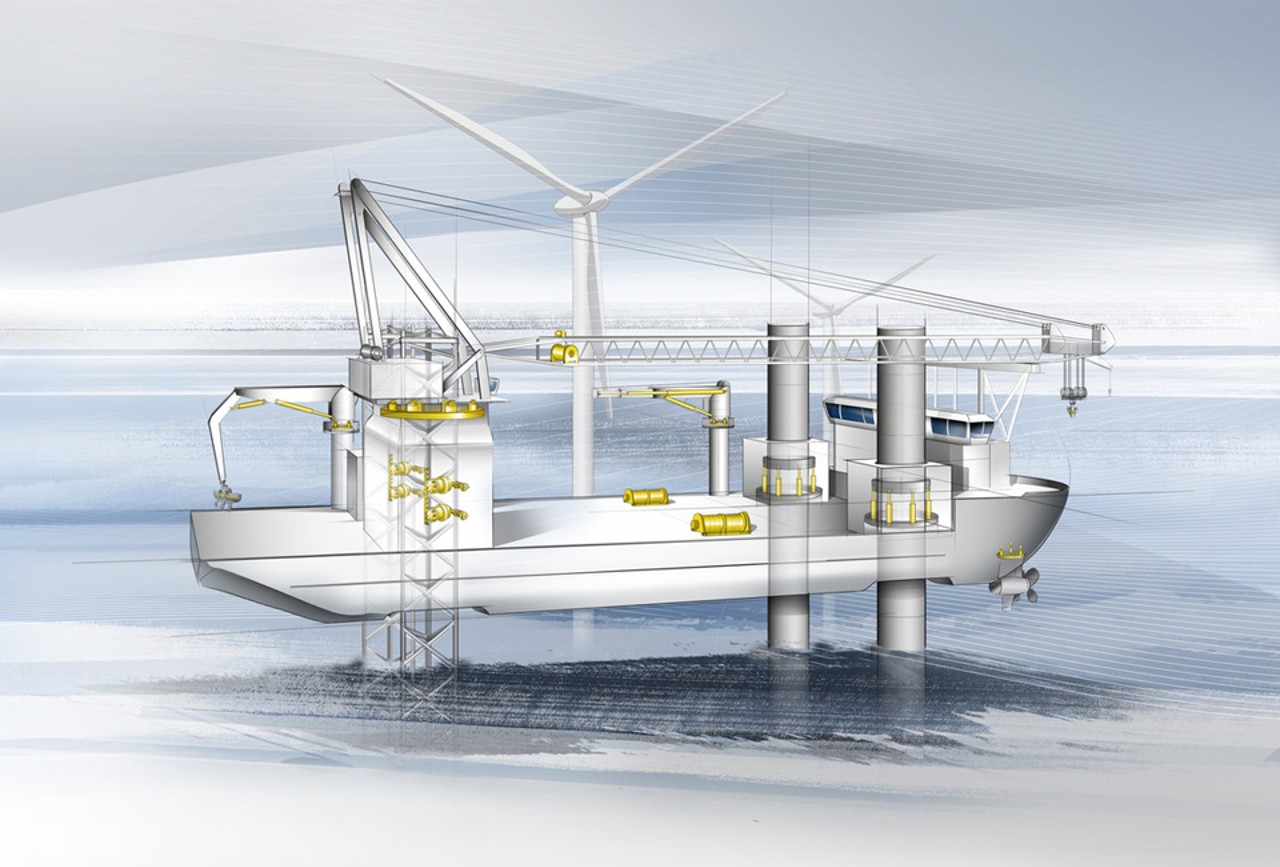

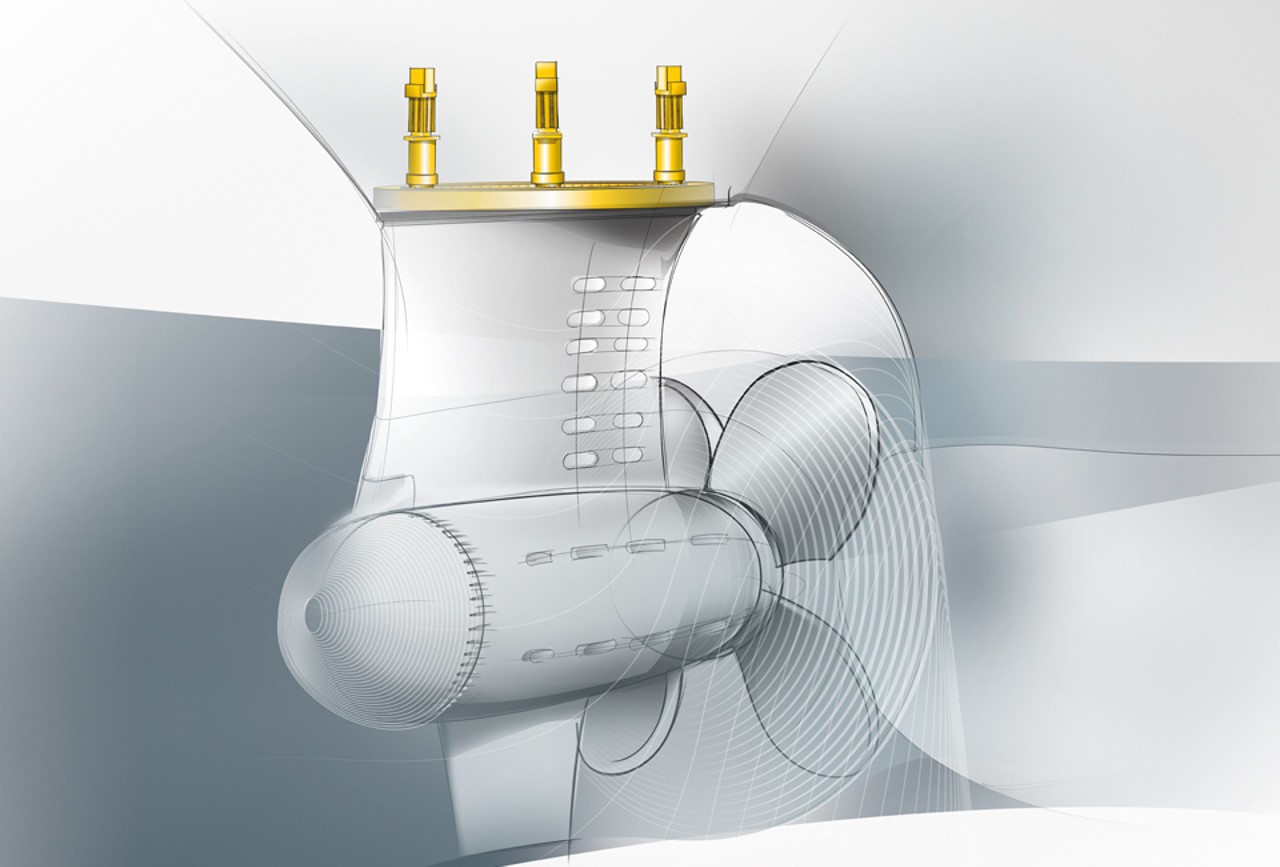

Drives for thruster

Made for harsh environments: The combination of Liebherr gearboxes, bearings and motors enables a perfectly harmonised system solution that meets the requirements of harsh environments.

Components for thruster

- Slewing bearings

- Slewing gearboxes

- Electric motors

Slewing bearings

Types: Roller / Ball-bearing slewing rings

External diameter: 800 – 9.500 mm

Rolling element diameter: 12 – 90 mm

Gearing: External / Internal/ Customized / No gearing

Advantages:

- Extremly durable

- Made for harsh environment conditions

- Special forms of seals

Slewing gearboxes

Types: DAT 400 – 500

Output torque: 44.000 Nm – 82.000 Nm

Gear transmission ratio: 1:29 – 1:250

Advantages:

- Over 60 years of experience

- Outstanding quality

- Reliability

- Low installation space required

- High power density

Licore Asynchronous Motors

Compact, weight-optimised, robust: The air-cooled Licore Asynchronous Motors (LAM) are designed as maintenance-free three-phase squirrel cage motors and stand out due to a high power density. The motors are primarily created for use in variable-speed drives with frequency converters as well as for highly dynamic applications.

Type: Squirrel cage

Power range: 7.5 – 160 kW

Voltage range: 400 / 690

Speed: 750 / 1.500 / 1.800 min-1

Rating: IP 54

Cooling: Air-cooled

Did you know?

Liebherr Maritime offers a wide range of advanced port handling equipment, ship and offshore cranes, as well as digital solutions and expert consulting. With innovative cable- and cylinder-luffing cranes in various sizes, Liebherr provides tailored solutions for cargo handling in global ports and the offshore industry.

Emission-free operations in harbours

A significant share of total emissions in port cities come from ships and machines in harbours. To actively drive forward the reduction of emissions, Liebherr engineers develop most efficient solutions for hybrid drives and energy storage systems. Based on extensive research and testing, we address our customer´s challenges in the electrification of local operations.

Energy storage systems to cover “hotel loads” of ships: Applications used in ports or at anchor can be driven by fuel cells to reduce local emissions. Fuel cells have a high inertia reacting to load fluctuations, therefore applications with high peak loads require an energy storage system to cover for power peaks.

Local regulations for cities and harbours: Liebherr keeps up with the overall and regional developments in regulations for construction sites. Within projects, we can provide necessary information on recommendations for actions or specific laws.

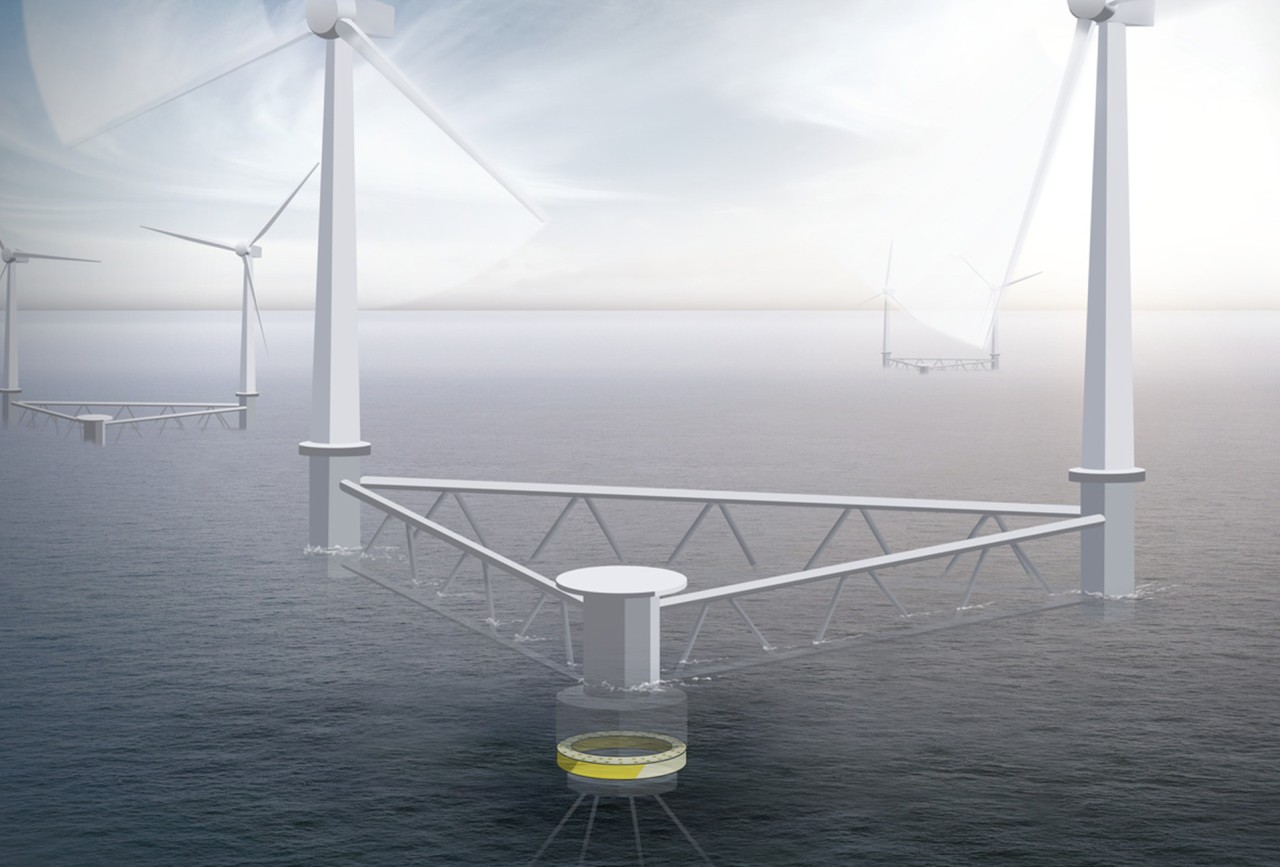

Slewing bearings for floating wind: tough, robust, durable

Slewing bearings ensure self-alignment of floating wind turbines

- Slewing bearings for floating wind turbines of Ming Yang Smart Energy

- Roller bearings function as a mooring-system for the self-alignment of the wind turbines

The Liebherr components product segment is part of a revolutionary project by Ming Yang Smart Energy: The Chinese manufacturer of wind turbines and provider of integrated solutions for clean energy has developed floating wind turbines. And Liebherr’s slewing bearings take care of their self-alignment.

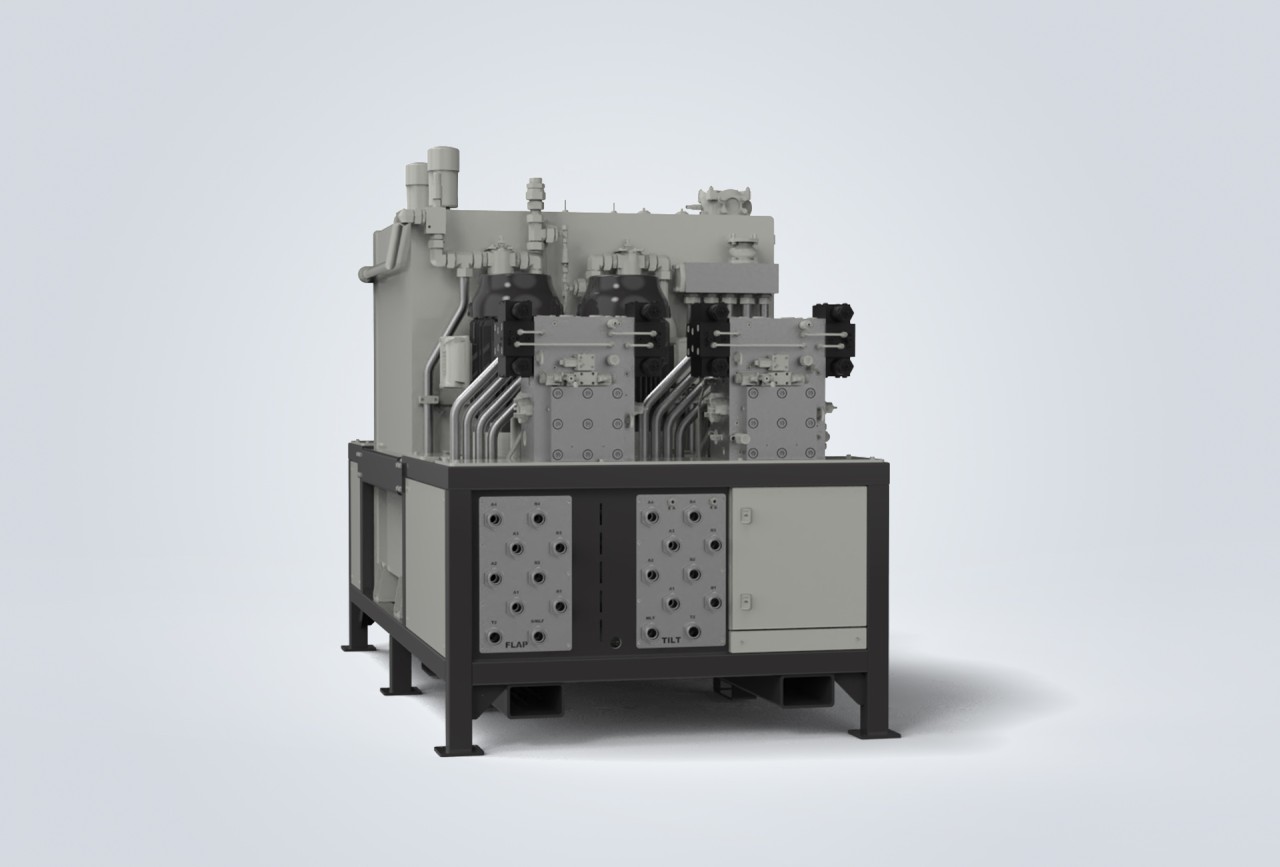

Hydraulic power unit for supplying oil to hydraulic cylinders and slew drives

The hydraulic power unit is used to supply oil to the tilting cylinders, the slewing cylinders and the slewing drive. These actuators perform the movements to raise, adjust or enlarge and rotate the ship's sail. In addition, the power unit has various monitoring elements such as pressure, temperature, contamination and level sensors, as well as proportional valve technology on the lowering brake valves. This provides a high level of safety and ensures that the hydraulic cylinders and slew drives function perfectly. The hydraulic power unit is prepared for installation in a shipping container.

Hydraulic power unit

Fuel tank capacity: 1750 l

Engine power: 3 x 22 kW

Operating pressure: 250 bar

Test pressure: 350 bar

Nominal volume flow at 1800 rpm: 3 x 180 l/min (axial piston pump) and 2 x 14 l/min (gear pump)

Weight: 5645 kg

Dimensions: 3,1 x 2,6 x 1,7 m