Machinery and plant construction

Machinery and plant construction comprises a range of sub-divisions. Among these are the production of machine tools and precision instruments as well as the manufacture of complete plant systems. This area of industry is distinguished by exceptional innovative strength.

Machines and plant systems that manage increasingly complex tasks and, at the same time, offer a high level of operating comfort are in line with current trends. Liebherr's powerful components contribute significantly towards efficient use of resources during production.

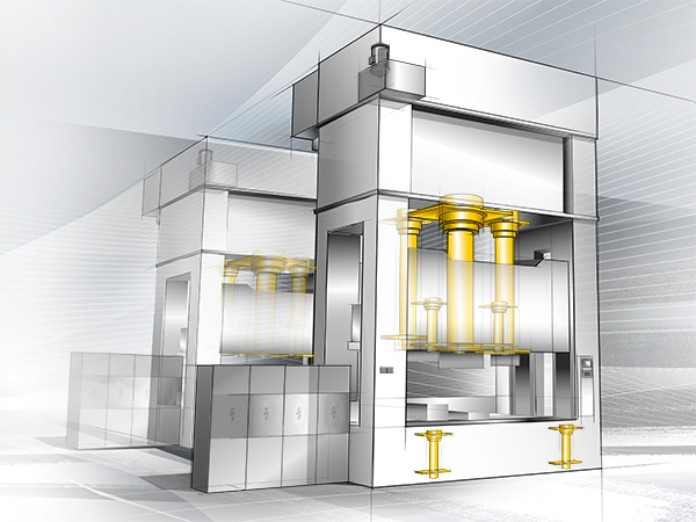

Liebherr components in machinery and plant construction

Liebherr offers a broad spectrum of components for use in machinery and plant construction. The interactive graphic shows the use of Liebherr components in this area using the example of a press.

Electric motors

Find out more

Hydraulic cylinders

Find out more

Control technology & electronics

Electronics

Find out more

Control cabinet

Find out more

Sample applications

Components from Liebherr are suitable for many applications in machinery and plant construction. Among the possible areas of application are machine tools and processing machines, production facilities and test instruments as well as other stationary systems.

- Panel processing machines

- Turning machines

- Die casting machines

- Blow moulding machines

- Plastic injection moulding machines

- Machines for food processing

- Nibblers

- Polishers

- Presses (e.g. extruders)

- Grinding machines

- Injection moulding machines

- Punch presses

- Stationary scrap presses

- Gear cutting machines

- Machine tools

- Motion simulators

- Rides

- Bottle filling plant

- Bottle blowing plant

- Power stations

- Measuring systems

- Test benches

- Satellite dishes

- Sluices

- Cableways

- Ski lifts

- Steel works

- Continuous caster systems

- Adjustable bridges

Components for machinery and plant construction

Liebherr components are used in a whole range of equipment in machinery and plant construction. Our portfolio offers solutions tailored to customer needs - from individual components to complete systems and services. We always bear application-specific requirements, such as high working speeds, small installation spaces and highest precision, in mind.

Advantages of Liebherr components

- Safe

Functional safety is of paramount importance in machinery and plant construction. Our control solutions fulfil the high demands from industry and are developed and manufactured in accordance with machinery safety standards (DIN EN ISO 13849). At the customer's request, we also offer UL-certified switchgear. - Diverse

Liebherr switch cabinets for industrial production machines cover a broad performance spectrum. This ranges from a few kilowatts up to the multi-megawatt range. Application-specific engineering services, such as the creation of circuit diagrams or software, round off our portfolio.

Liebherr electric motors of the KGF and KDF series are distinguished by compact dimensions and optimised cooling. In this way, they negate any doubt regarding the compatibility of customer-specific design and cost effectiveness.

- Compact

An innovative design with self-supporting housing makes it possible to construct motors with reduced volume. These can be integrated into any system without trouble. - Optimal cooling

Our electric machines ranging from 7.5 to 650kW feature a wide range of different cooling options. - Economical

High availability values during operation safeguard the efficiency of our machines and reduce total costs of ownership. - Resilient

The winding and bearings in Liebherr electric motors are orientated around eliminating or resisting harmful side effects such as bearing currents and voltage spikes. - Compatibility

Optimum compatibility with other Liebherr components, such as inverters or gearboxes, means that the system can be brought into operation quickly. - Durable

The high availability of spare parts and a fast, obliging service guarantee a long service life of our electric motors.

- Durable

The sturdy design of the Liebherr hydraulic cylinders ensures a long service life even with high working speeds. - Customer-specific

Experienced engineers design our hydraulic cylinders according to customer-specific needs and orientate themselves around the requirements of each application. - Low friction

Thanks to the use of low friction sealing systems, our cylinders ensure very smooth running and high energy efficiency of the hydraulic system.

Specifically designed products

- Cylinder sensors

Sensor components are ideally matched to our cylinders. In this way, they enable optimum control of complex hydraulic systems.

- Diverse

The Liebherr product portfolio comprises axial piston units for the open circuit in the high and medium pressure range. - Durable

Hydraulic motors from Liebherr are characterised by a favourable bearing load and a compact design. This ensures a particularly long service life.

Specifically designed products

- Axial piston pump DPVO

The pumps with open circuit and inverse piston technology are designed especially for high pressure applications and can be used e.g. in presses, steel works or test benches. The hydraulic pumps impress with their large swing angle and high resistance to pressure. They offer a through-drive of 100 percent and can be combined with all conventional controllers. - LH30VO axial piston pump

The medium pressure pump LH30VO is suitable for linear equipment movements, e.g. during manufacture of injection moulded parts. With our experience from the high-pressure range, the pump was designed for a long service life. Optimised production processes make it very cost effective.