More about the company

Liebherr careers

We dig it!

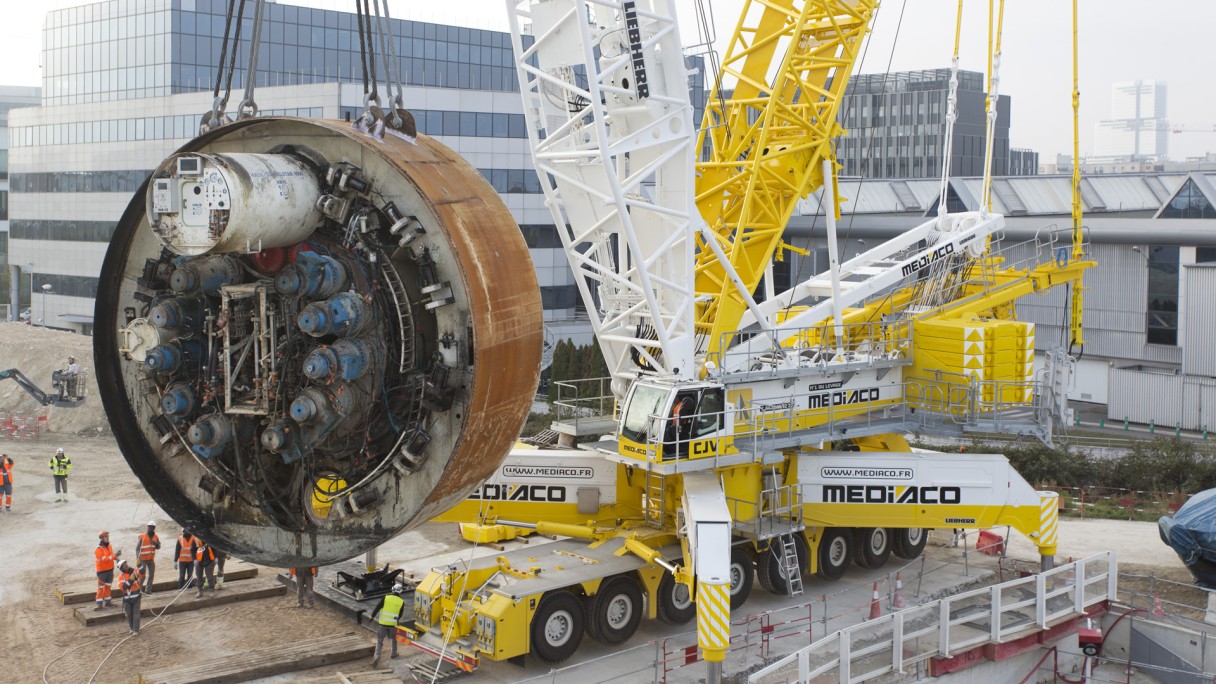

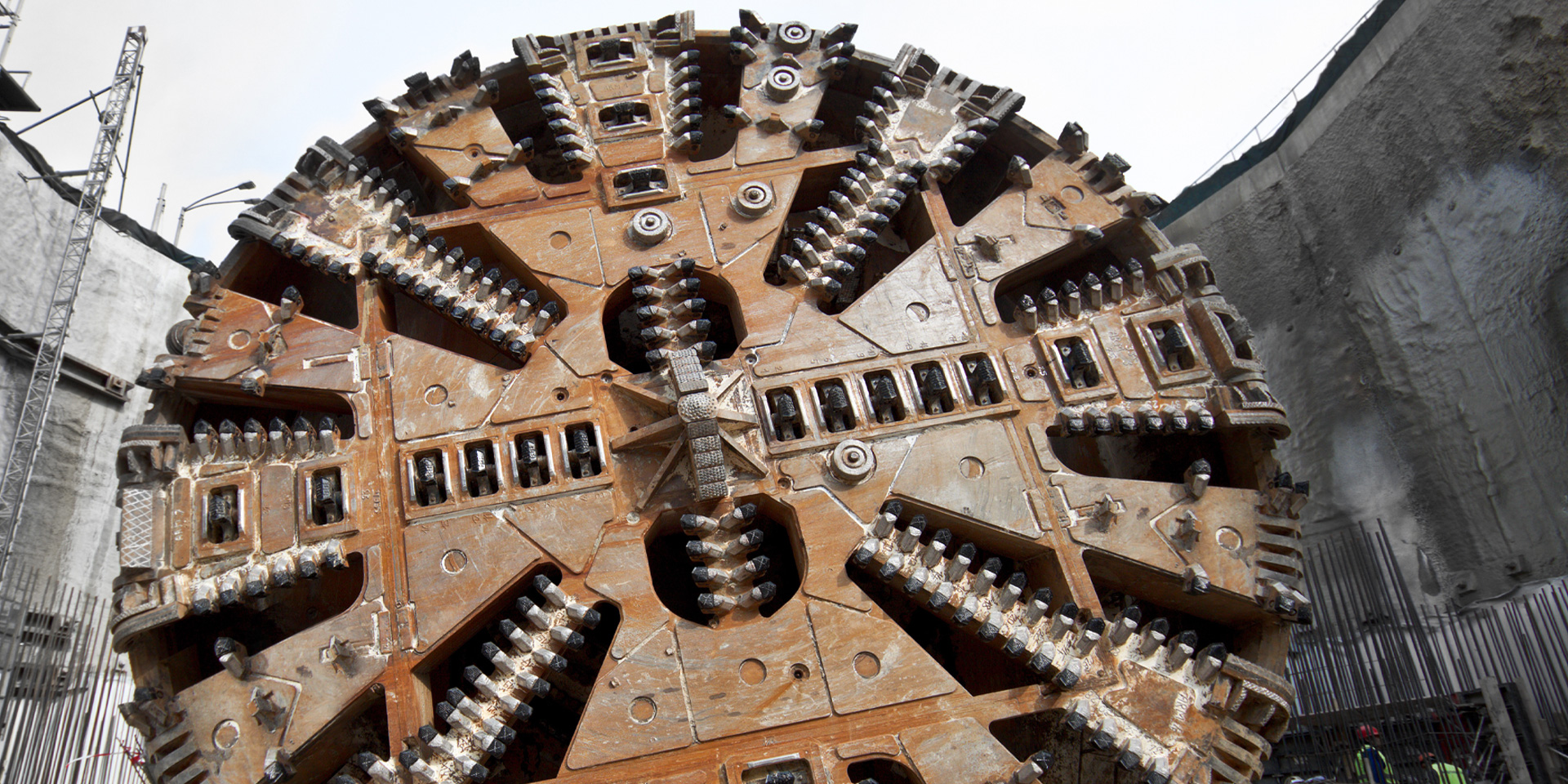

Liebherr components for tunnelling are specifically designed for toughest loads in continuous operation and have a proven track record of success in the field. You will find them in tunnel boring machines from renowned companies in numerous tunnel boring projects all around the world.

No time for downtime

Tunnel boring equipment is facing several challenges during operation. On the one hand there are extreme soil conditions, from hard rock to erosive soil and EPB. On the other, long project scopes and narrow timeframes with short reaction times. Given these circumstances, one thing is clear: You have no time for machine-downtimes.

In order to assure a successful project completion it is therefore essential to have, above all, reliable equipment.

Premium components for your tunnel boring productivity

You can rely on Liebherr components at all times. They are designed for toughest loads in continuous operation and are thoroughly tested on the company‘s own test benches. Whether it‘s a railway tunnel in Siberia or a new metro line in Mumbai - Liebherr components have successfully been put to use in the field. Renowned global companies are using Liebherr’s portfolio for numerous tunnel boring projects all around the world.

“Liebherr is more than a supplier, they are a partner that we can depend on to supply the most critical components on our machine.”

Mike Koelnich, Director of Supply Chain at the Robbins Company

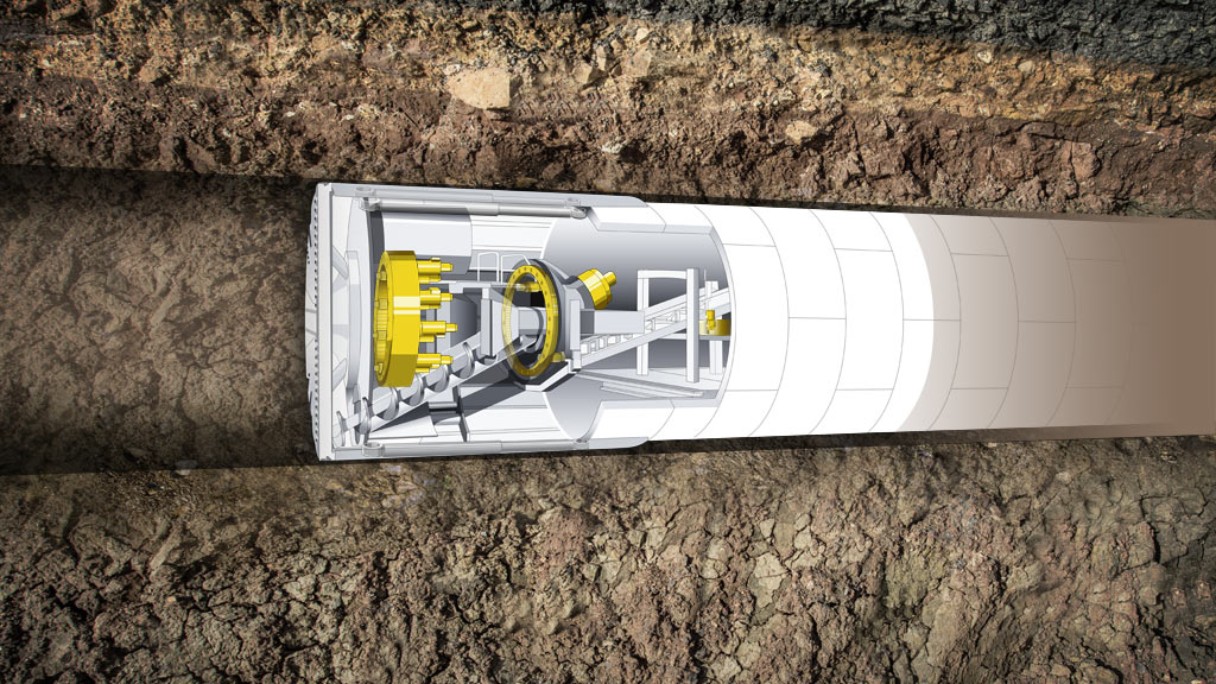

Make the breakthrough: Components for Earth Pressure Balance (EPB) tunnel boring machines

Axial piston double motor DMVA D

- Variable displacement double motor in swashplate design

- Proven robustness and reliability

- High conversion range, rotation speed and pressure levels

- Rotary groups are separately and parallely adjustable

- Through-drive possability

- Only half the amount of high pressure lines needed thanks to a shared port plate

Heavy metal vs. hard rock: Components for hard rock tunnel boring machines

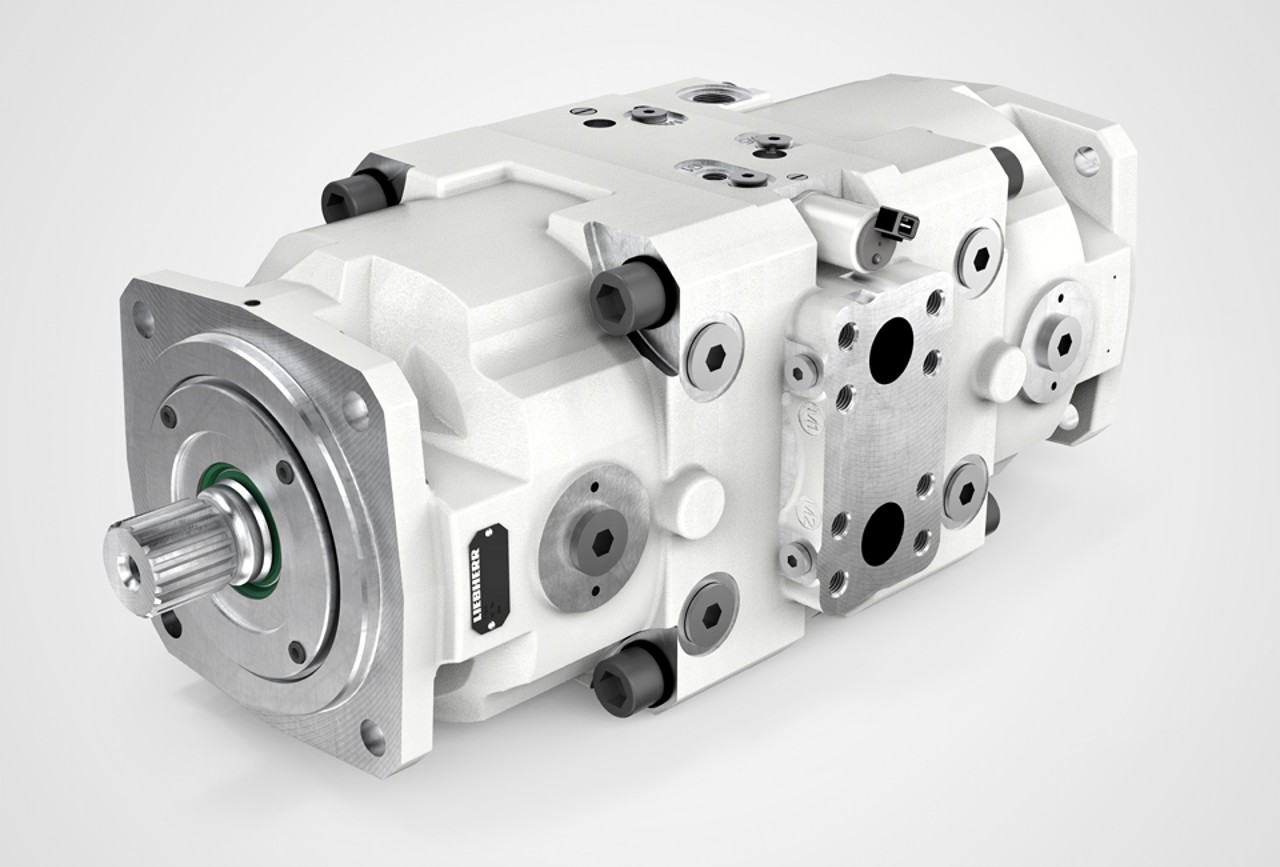

Axial piston pump DPVO

- Variable displacement pump in swashplate design

- Proven robustness and reliability

- Interchangeability due to different mounting flanges

- Long lifetime and high compressive strength

- Operates under harsh environmental conditions

- Through-drive possibility of 100%

Camera monitor system for TBM

- True-colour and detailed HD images even under challenging lighting conditions – with an illuminance level of 1 millilux

- Several smart functions to process the image in the camera itself

- Robust solution for demanding environmental conditions

IoT gateways for TBM

- Future-proofing and flexibility through open programmability

- Easy cloud connection and edge computing for data pre-processing

- Data security with our chain-of-trust concept

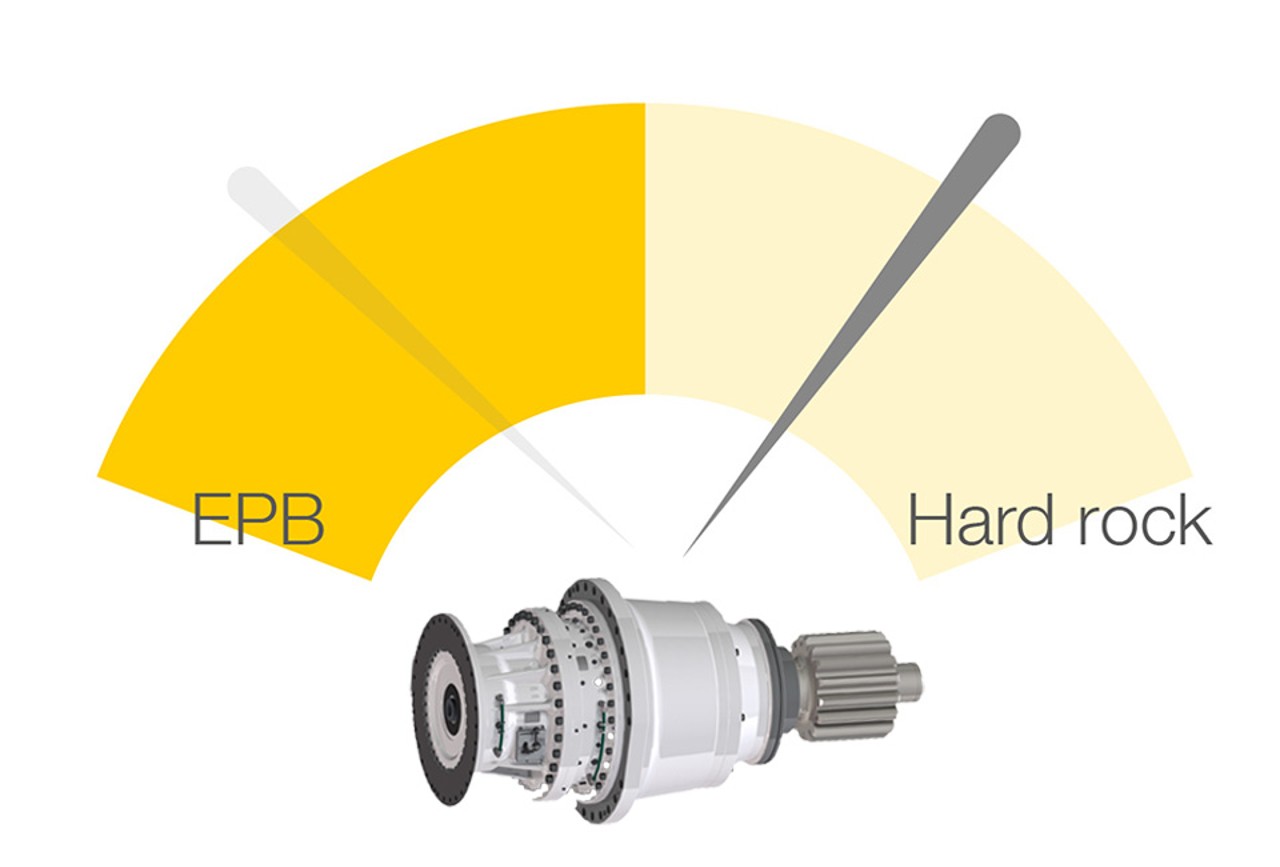

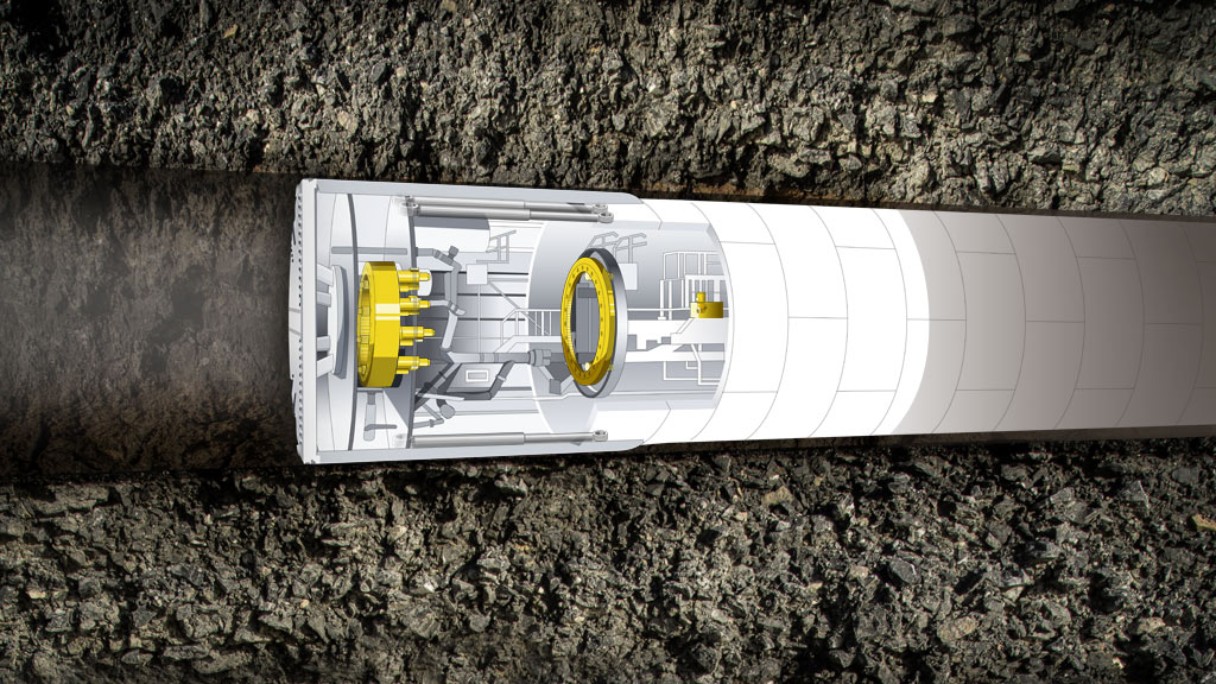

Whatever may come: Components for dual mode tunnel boring machines

Shift gears for cutter heads

- combine EPB and hard rock soil conditions in one tunnel boring machine

- time-saving speed adjustment of the cutter head

- require no more machine compromise for various soil conditions

- energy efficient operation at optimum engine speed

- separated oil supply and cooling circuit

- retrofitable with existing machines or gearboxes

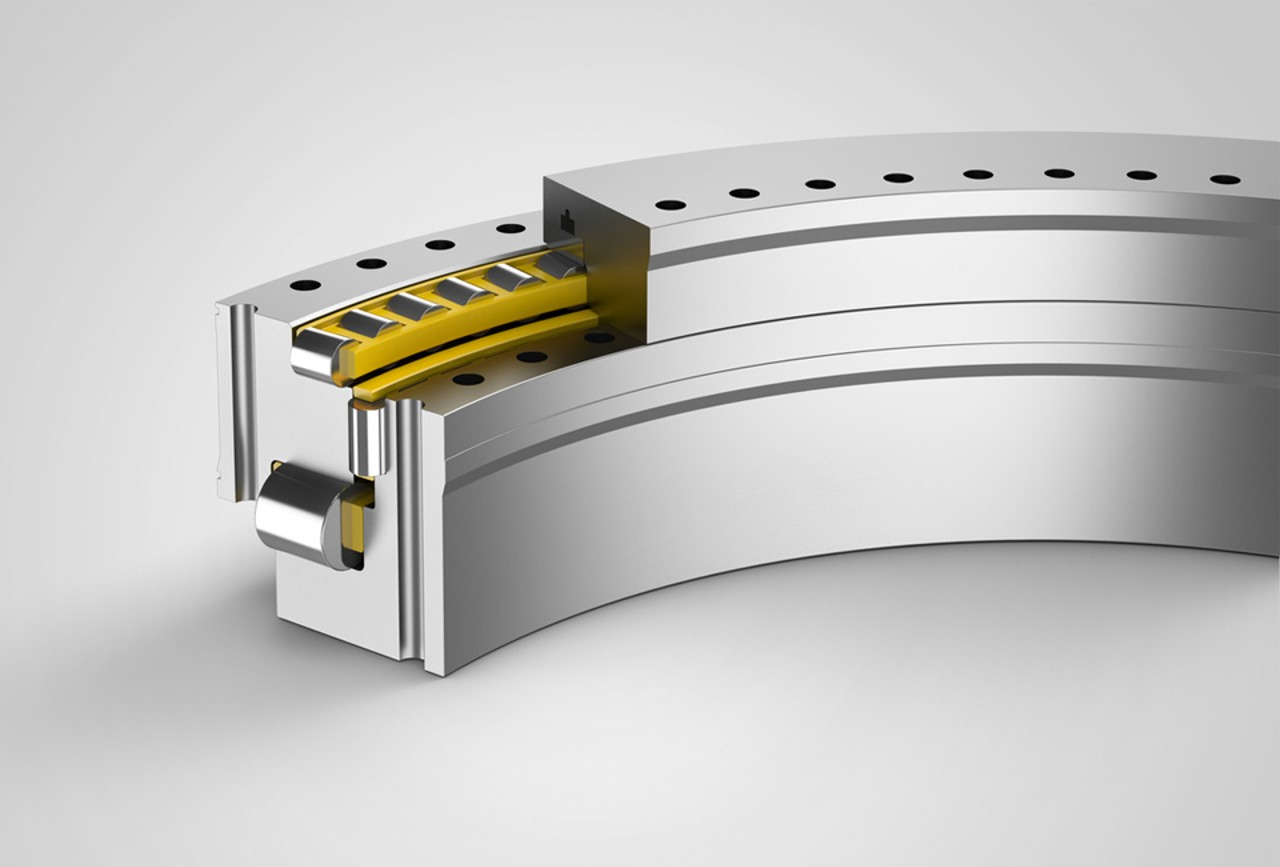

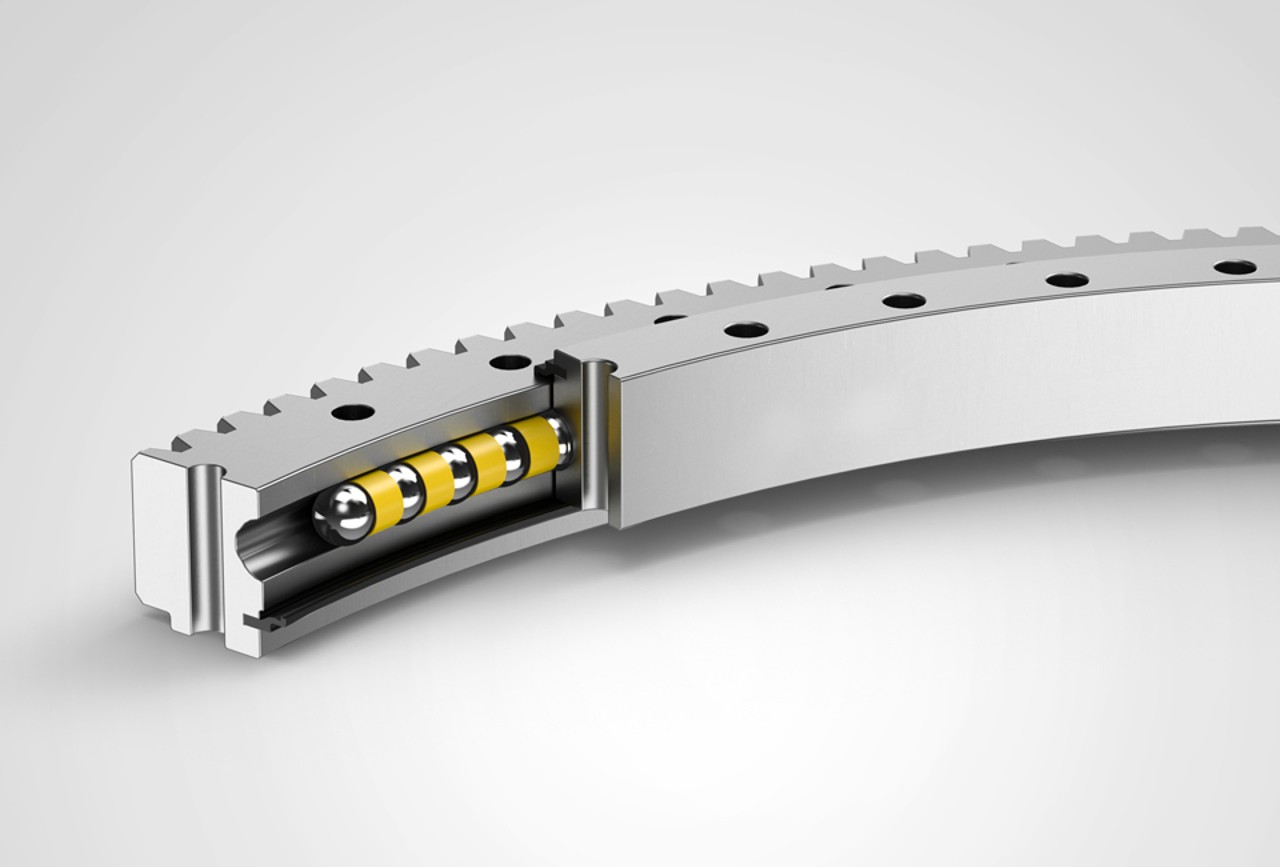

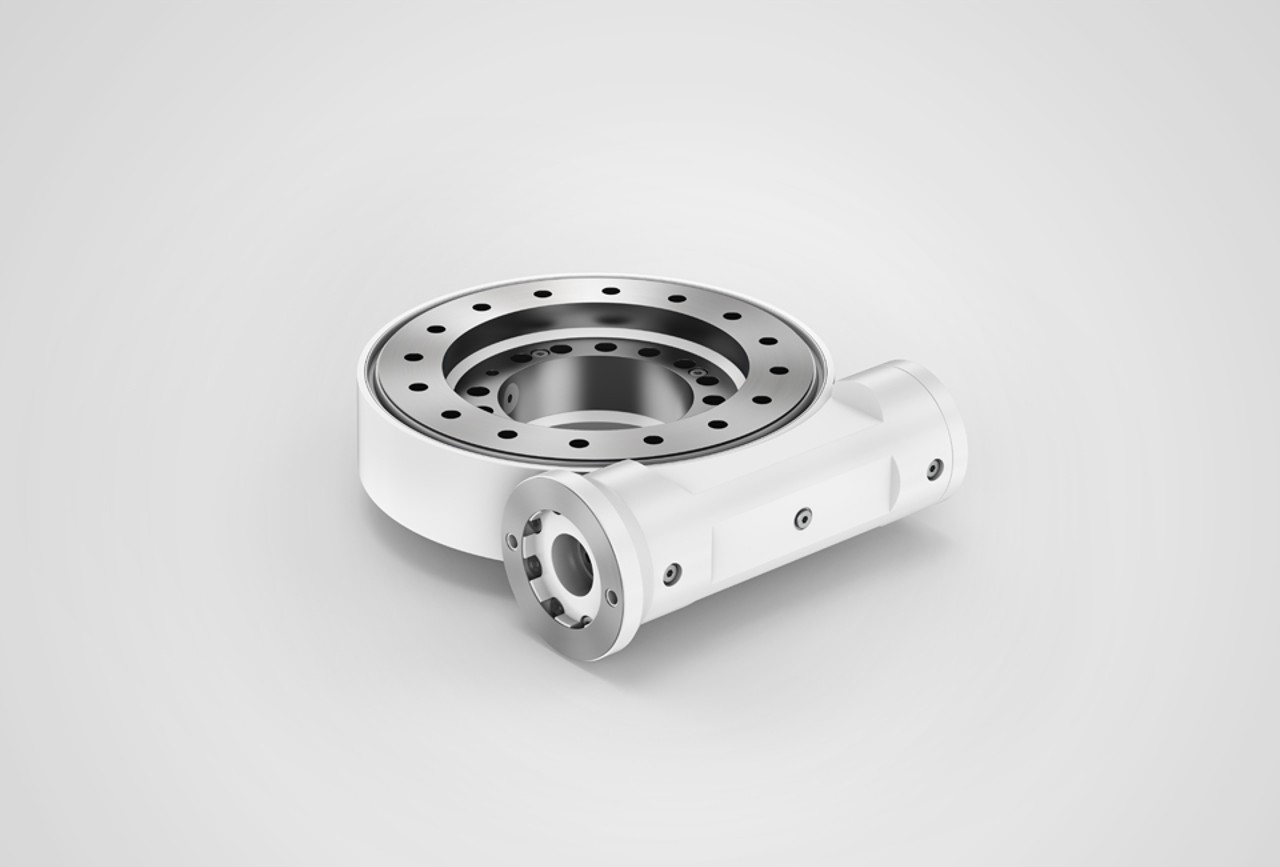

Erector drives

- High-precision movement

- Low noise level

- Low backlash

- Compact design

- High range of ratio

Drives for screw conveyor

- Hydraulic or electric driven

- Integrated cooling system

- Cusomised design

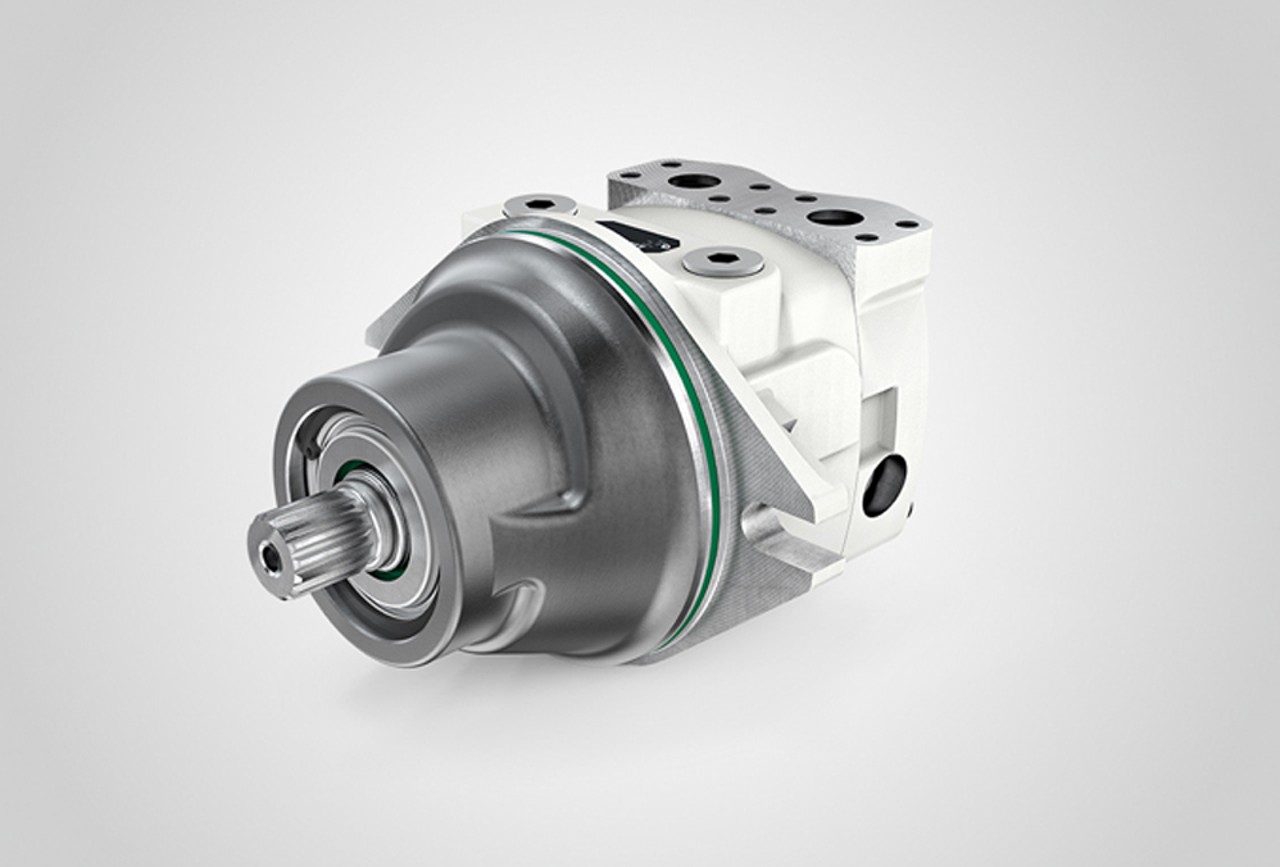

Axial piston motor FMF

- Fixed plug-in motor in swashplate design

- Proven robustness and reliability

- Available both with and without integrated valves in the port plate

Axial piston pump DPVO

- Variable displacement pump in swashplate design

- Proven robustness and reliability

- Interchangeability due to different mounting flanges

- Long lifetime and high compressive strength

- Operates under harsh environmental conditions

- Through-drive possibility of 100%

Camera monitor system for TBM

- True-colour and detailed HD images even under challenging lighting conditions – with an illuminance level of 1 millilux

- Several smart functions to process the image in the camera itself

- Robust solution for demanding environmental conditions

IoT gateways for TBM

- Future-proofing and flexibility through open programmability

- Easy cloud connection and edge computing for data pre-processing

- Data security with our chain-of-trust concept

Reference stories

Why do companies like the Robbins Company choose Liebherr components for their tunnelling projects? Request our reference story here and discover your possibilities.

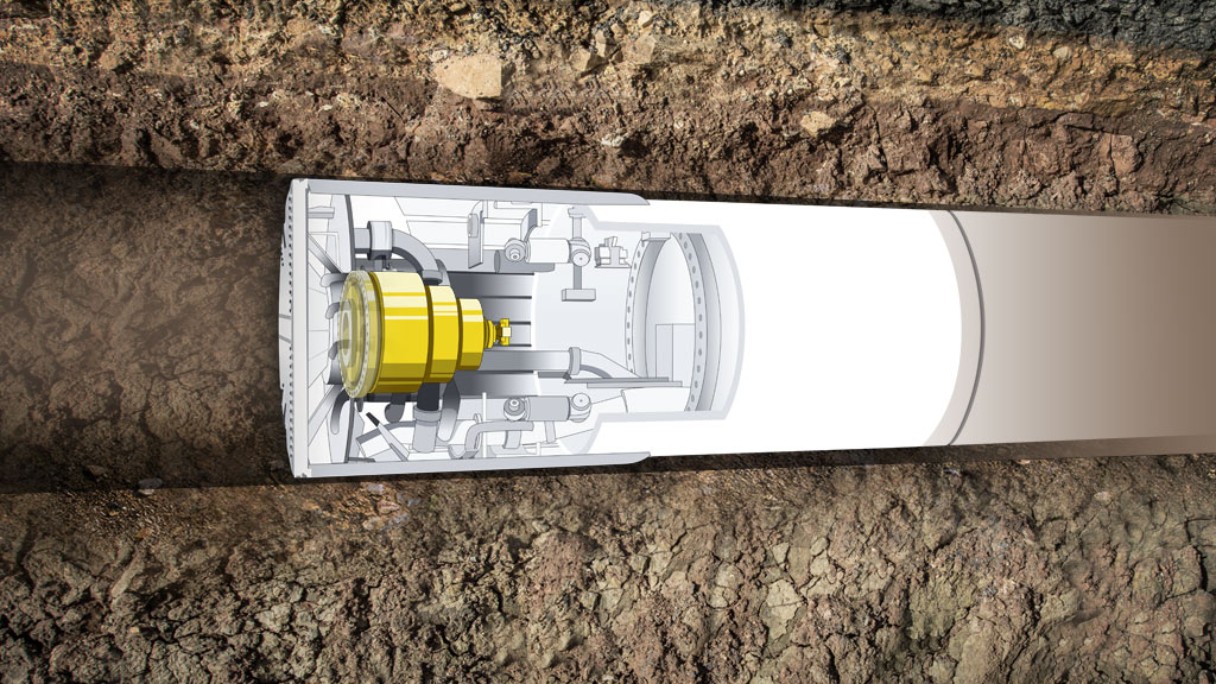

Like a large-diameter worm: Components for micro tunnel boring machines

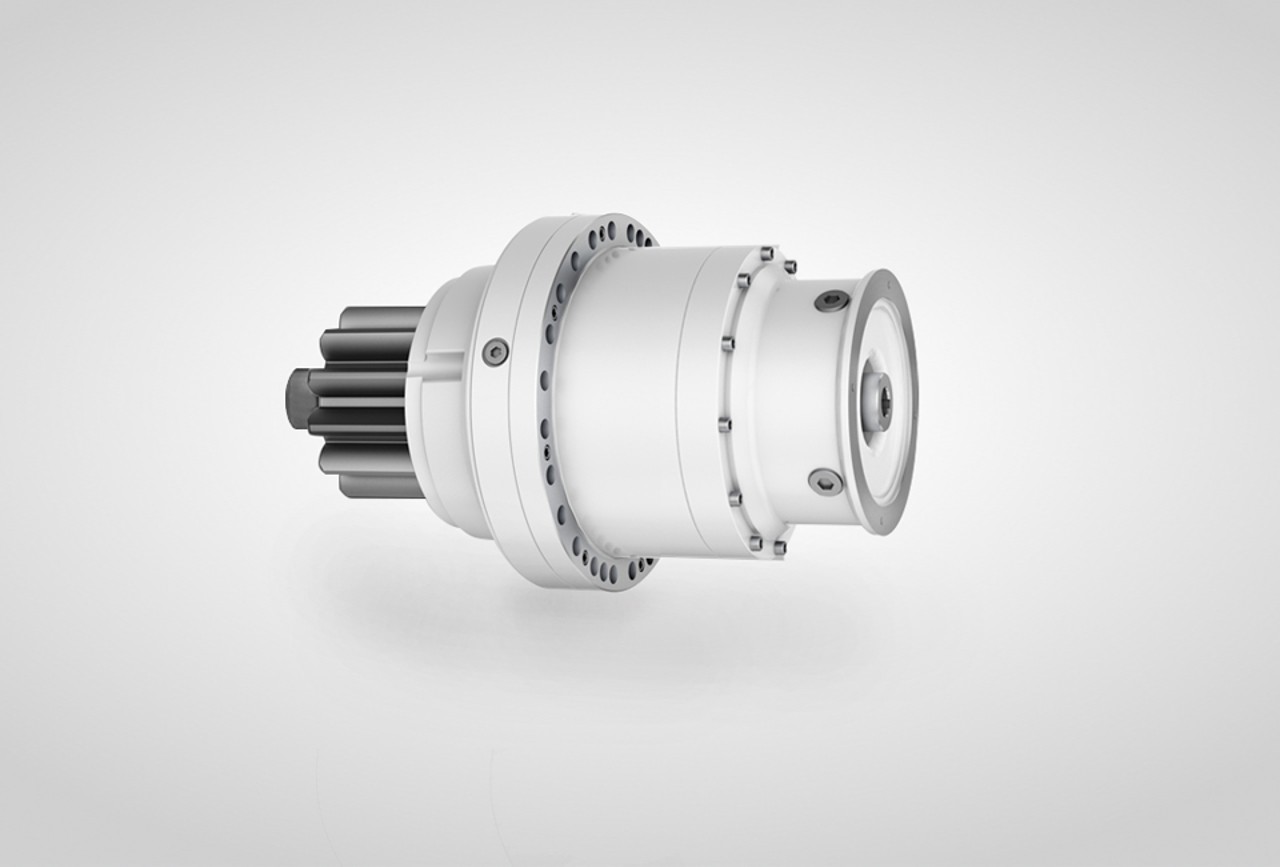

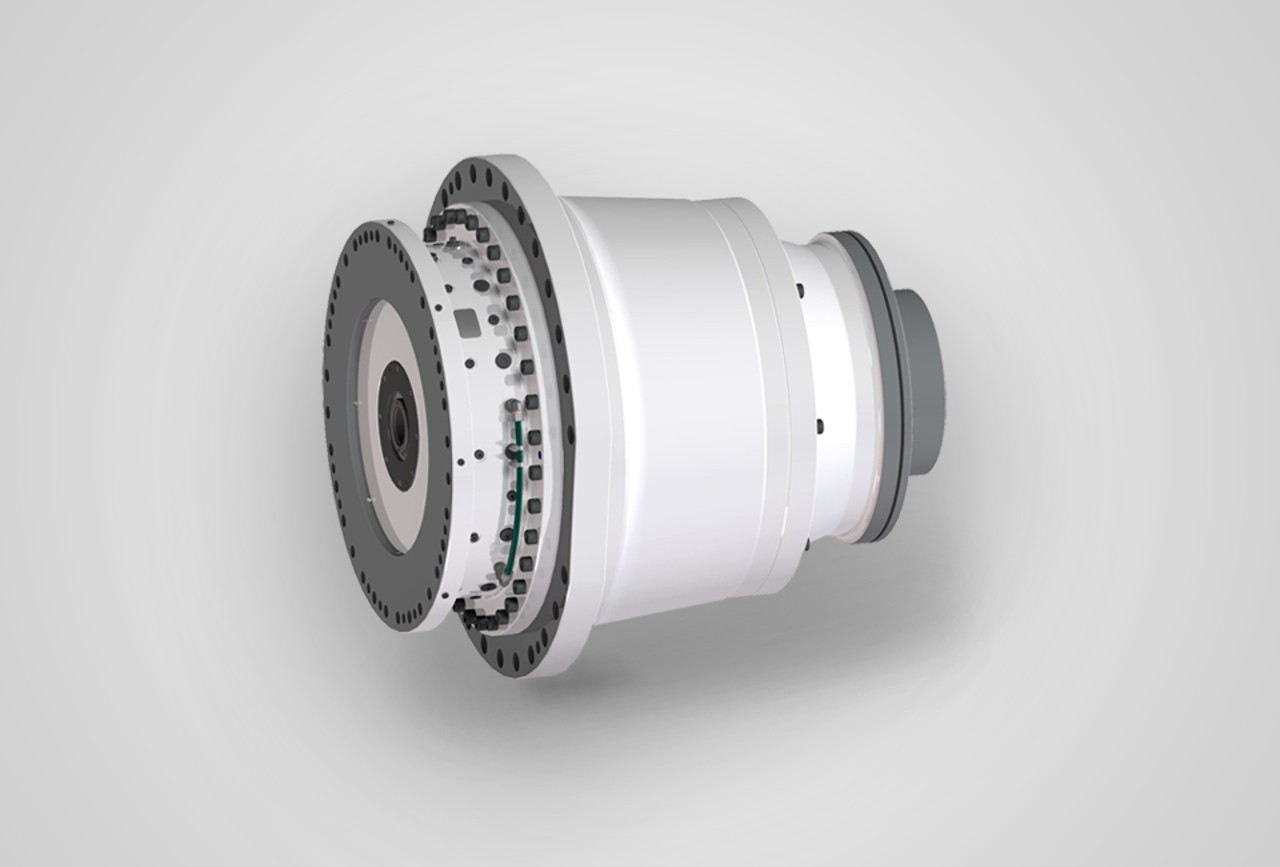

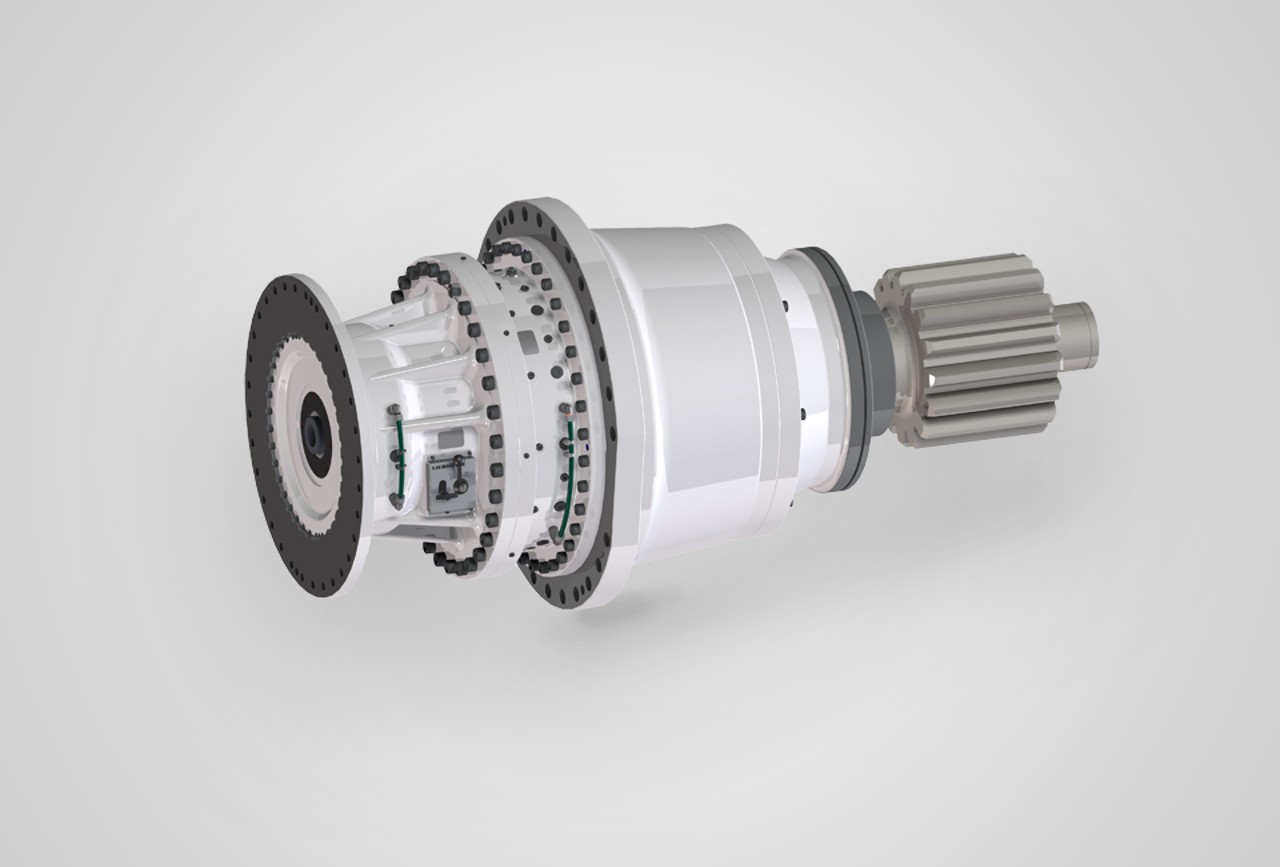

Planetary gearbox for central drives

- hydraulic or electric driven

- integraded cooling system

- customised design

Axial piston pump DPVO

- Variable displacement pump in swashplate design

- Proven robustness and reliability

- Interchangeability due to different mounting flanges

- Long lifetime and high compressive strength

- Operates under harsh environmental conditions

- Through-drive possibility of 100%

Camera monitor system for TBM

- True-colour and detailed HD images even under challenging lighting conditions – with an illuminance level of 1 millilux

- Several smart functions to process the image in the camera itself

- Robust solution for demanding environmental conditions

IoT gateways for TBM

- Future-proofing and flexibility through open programmability

- Easy cloud connection and edge computing for data pre-processing

- Data security with our chain-of-trust concept

Make your TBM even better with innovations from Liebherr